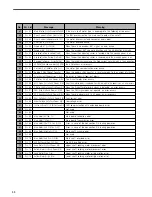

Setting the parameter related to general sewing

Function number related to pattern programming

0)

TRIM

1)

SEC-ORG

2)

PAUSE

3)

EMPTY

4)

JUMP

5)

POINT

6)

LINE/CURVE

7)

LINE

8)

CURVE

9)

ARC

10)

CIRCLE

11)

JUMP SPD

12)

STI SPD

13)

STI WIDT

14)

PTRN READ

15)

PTRN WRITE

16)

FORMAT

17)

INFO DISP

18)

CORD SYS

19)

LINE ZIG

20)

CURVE ZIG

21)

ARC ZIG

22)

CIRCLE ZIG

23)

LINE OFST

24)

CURVE OFST

25)

ARC OFST

26)

CIRCLE OFST

27)

LINE DBL

28)

CURVE DBL

29)

ARC DBL

30)

CIRCLE DBL

31)

LINE DREV

32)

CURVE DREV

33)

ARC DREV

Trimming

2nd origin

Temporary suspension

One turn of sewing machine

JUMP

Point sewing

Linear/Curving line sewing

Linear sewing

Spline sewing

Arc sewing

Circle sewing

Change of jump speed

Change of stitching speed

Partial Sewing Stitch Width Change

Pattern data reading from USB flash drive

Pattern data writing to USB flash drive

USB flash drive formatting

Information indication of present pattern data

Coordinates setting

Linear zig-zag sewing

Spline zig-zag sewing

Arc zig-zag sewing

Circle zig-zag sewing

Linea offset sewing

Spline offset sewing

Arc offset sewing

Circle offset sewing

Linear double sewing

Spline double sewing

Arc double sewing

Circle double sewing

Linear double reverse sewing

Spline double reverse sewing

Arc double reverse sewing

Circle double reverse sewing

34)

CIRCLE DREV

35)

LINE REV

36)

CURVE REV

37)

ARC REV

38)

CIRCLE REV

39)

PTRN DEL

40)

BACK TACK

41)

CNDNS STI

42)

OVLAP STI

43)

SYMMETRY X

44)

SYMMETRY Y

45)

SYMMETRY P

46)

MOVE PTRN

47)

COPY PTRN

48)

DEL PTRN

49)

REV SET

50)

SPD CHNG

51)

STITCH DRAG

52)

STITCH DEL

53)

MOV SEWSTRT

54)

MOV 2ndORG

55)

Auto TRIM

56)

SCALE REFER

57) SET_OPnn

58) CHK_IPnn

59) TIME_DELAY

60)

PF_CONTROL

61)

EXT OP

62)

EXT IP

63)

SET TR3

64)

MODIFY

81)

82)

Guide End Pnt

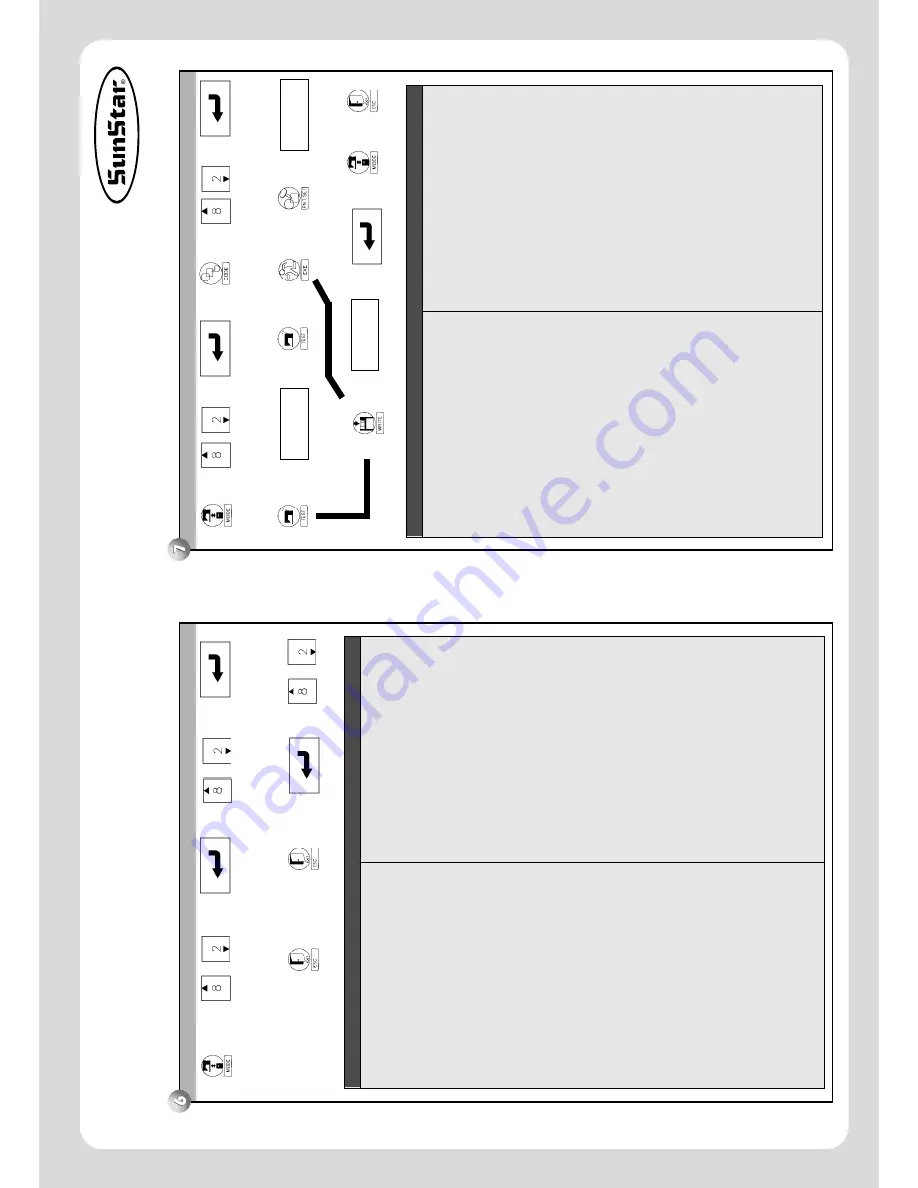

Pattern programming : Generating the pattern that users want

➞

➞

➞

➞

➞

➞

➞

➞

“1. PARAMETER SET”

Parameter no. set

Change of setting

value/condition

➞

➞

➞

➞

➞

➞➞

➞

➞

“2. PROGRAM”

Pattern saving

Generation of relevant

code data

Test sewing

Selection of function

related to programming

Mode key

➞

➞

➞

➞

➞

➞

➞➞

➞

IInn

ppuu

tt o

off

dd

aatt

aa w

w

iitthh

ddii

rree

cctt

iioo

nn//

ddii

ggii

tt k

kee

yyss

IInn

ppuu

tt o

off

pp

aatt

ttee

rrnn

nnoo

.. w

w

iitthh

dd

iigg

iitt k

kee

yyss

PP

eedd

aall

ss

ww

iittcc

hh

Linear reverse sewing

Spline reverse sewing

Arc reverse sewing

Circle reverse sewing

Partial Pattern Data Delete Function

Addition of automatic back-tack

Condensed Sewing Stitch Adding

Addition of overlap stitch

X-axis Symmetrical Data Addition

Y-axis Symmetrical Data Addition

Point Symmetrical Data Addition

Partial Movement of Pattern Data

Copying Function of Pattern Data to Specific Location

Deletion of pattern data

Partial Pattern Data Delete Function

Change/Saving Function of Maximum Pattern Sewing

Speed and Extension/Reduction Rate

One Stitch Movement Function

A Fixed Number of Stitch Delete Function

Change/Saving Function of Pattern

Data Start Point

Change/Saving Function of Pattern

2nd Original Point

Setting-up automatic thread trimmer

Setting-up user-defined reference point for zooming

User Output Port Setting Upon Programming�

User Input Port Setting Upon Programming�

Entry of User Lapse Time Upon Programming

User's Presser Foot Height Setting

Extended I/O board output port setting

Extended I/O board input port setting

3rd thread adjustment device setting

Modifying function for section design

Formation function for pocket design only

Setting function for pocket guide end point

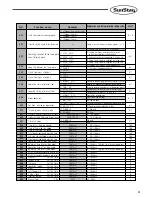

Parameter number related to general sewing

000 001 002 003 004 005 006 007 008 009 010 011 012 013 014 015 016 017 018 019 020 021 022 023 024 025 026 027 028 029 030 031 032 033 034 035 036 037 038 039 040 041 042 043 044 045 046 047 048 049 050 051 052 053 054 055 056 057 058 059 060 061 062 063 064 065 066 067

Jog En/Dis Jog Mode Machine Org1 Machine Org2 Strt Ret Mod Bobbin Count Prodct Count Pattern Read Trim EM Stop Slow Start User_Slow_1 User_Slow_2 User_Slow_3 User_Slow_4 User_Slow_5 User_Slow_6 User_Slow_7 User_Slow_8 User_Slow_9 User_Slow_10 Max Speed Feed End Pos FF Operation FF Close En Pedal 1 Mode Pedal 2 Mode PF Operation PF Down Mode WP Operation WP Position Thrd Detect Thrd Stitch 1 Thrd Stitch 2 Trim En/Dis Jog Time 1 Jog Time 2 Jog Time 3 Con Key Tm 1 Con Key Tm 2 Con Key Tm 3 Elc WP On Tm Elc WP Off Tm Air WP On Tm Air WP Off Tm PF Down Time PF Up Time PF Full On Tm FF Full On Tm TT Full On Tm TH Full On Tm WP Full On Tm FFLFull On Tm TS Full On Tm RV Full On Tm PF Duty FF Duty TT Duty TH Duty WP Duty FFL Duty TS Duty RV Duty PTRN RD MODE Scale Mode Chain Number Chain Select Chain Clamp Decel Stitch

Manual Operation En/Dis Moving to start position/the 2nd origin by manual drive Return to the machine origin after finishing sewing operation Return to the origin when limit error occurs Return mode to the sewing start position Counting method for bobbin count Use of products counter Time for reading patterns Trimming during emergency stop Acceleration characteristics of main-shaft speed 1st

Needle Speed Setting

2nd

Needle Speed Setting

3rd

Needle Speed Setting

4th

Needle Speed Setting

5th

Needle Speed Setting

6th

Needle Speed Setting

7th

Needle Speed Setting

8th

Needle Speed Setting

9th

Needle Speed Setting

10

th

Needle Speed Setting

Maximum speed limit of sewing Opening angle of feed plate transfer Operation condition of feed plate when sewing operation finishes Descent maintenance of upper feed plate Signal mode of Pedal 1 Signal mode of pedal 2 Setup for presser foot operation Setup for descent time of presser foot Setup for wiper operation Setup for wiper operation position Setup for thread detection Detecting the stitch number in starting sewing Detecting the stitch number during sewing Use of trimming function Manual operation time in speed level 1 Manual operation time in speed level 2 Manual operation time in speed level 3 Time for function of the speed level 1 key Time for function of the speed level 2 key Time for function of the speed level 3 key Electric wiper operation time Electric wiper standby time Pneumatic wiper operation time Pneumatic wiper standby time Standby time for completely lowered presser foot Standby time for completely uplifted presser foot Presser foot full on time Feed plate full on time Thread trimming full on time Thread Retaining Full On Time Wiper full on time Left feed plate full on time 2 step stroke full on time Inverting device full on time Presser foot duty Feed plate duty Thread trimming duty Thread retaining duty Wiper duty Left feed plate duty 2 step stroke duty Reverting device duty Pattern data reading mode Setting the magnifying/demagnifying mode Number of chain sewings Transferring chain numbers Set the clamp when the chain is used Number of stitches to decelerate before ending work

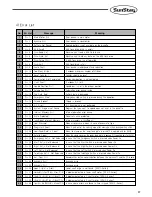

068 069 070 071 072 073 074 075 076 077 078 079 080 081 082 083 084 085 086 087 088 089 090 091

092

093

094

095

096

097

098 099 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122

123 124 125 126

Decel SPM Trim Trim Delay Low Pressure FF Number FF PauseCntl Thrd Hold En Upper Clamp En ConKey3 Num Scale Refer Palette Chk Sewing Limit XPLUS Limit XMINUS Limit YPLUS Limit YMINUS Limit FFOrign 1811 RevAfterTrim ReverseAngle Save Type DsgnOpnCtrl Safety Mode Jump Speed Jump EM_SW Jump PF Ctrl

PF Code Ctrl

Clamp En/Dis

Clamp Data

PF En/Dis

Clamp Range

PF Range

Auto Call Auto Ready Attatch Set AutoCall TM AutoNumSet EX_IO BD SET Thumbnail Set HookORG MODE HEAD En/ Dis Oil Control Oil Off Time ThHold En/Dis ThreadHoldTm NeedleCoolSet NeedleControl NeedleOffTime Set Trimmer Head Sensor Clamp Sensor BCODE ORG SET BARCODE TYPE Trim St Angle Thrd Hold Angle PF Motor Used JumpTention

Program Lock Clmp Ref Pos Cassette Type UpStop Pos

Decelerating speed before ending work Thread trimming delayed time The selection of the low pressure detecting device Feed plate control Upper feed plate control when paused Whether to use thread tension adjusting plate after thread trimming Upper feed plate control Back/Forth jump stitches Setting-up reference point for zooming Palette signal check Sewing limit set-up X-axis forward direction sewing limit set-up X-axis reverse direction sewing limit set-up Y-axis forward direction sewing limit set-up Y-axis reverse direction sewing limit set-up Quick origin search motion selection for 1811 Setting reverse rotation after trimming Set reverse rotation angles after trimming Save Type Setting Deleting Other Designs When Opening New Design Setting the Safety Mode Jump Speed Setting Emergency Stop Switch Setting During Jump Motion Presser Foot Lift Setting During Jump Motion (depending on the presser foot motor specifications) Presser Foot's Thickness Difference Control Code Setting (depending on the presser foot motor specifications) Clamp Move Enable/Disable (limited to the clamp motor- equipped models) Primary Use of User-Defined Clamp Move Enable/Disable (limited to the clamp motor-equipped models) PF Height Control Enable/Disable (limited to the presser foot motor-equipped models) Clamp Height Setting (limited to the clamp motor-equipped models) Presser Foot Height Setting (limited to the presser foot motor-equipped models) Design auto call Sewing ready setting upon design auto call External Control Signal Setting Design call sensor time setting Design Auto Call Group Setting Extended I/O board setting Design Preview Setting Upper/Lower Shaft Origin Search Motion Setting HEAD Up/Down Setting Oil Spray Time Setting Set the oil spraying motion end cycleg Upper thread holder setting Upper thread holder's needle thread holding time setting Needle Cooling Setting Needle Cooling Time Setting Needle cooling off time cycle setting Trimming method setting Setting the head sensor Clamp Sensor Setting Barcode origin point selection Set barcode Type Needle bar upper stop position setting Set up the entry angle of pneumatic upper thread holder Set up the presser stepped pulley motor Setting the opening of the thread release device for jump section Setting a lock to the program mode Setting the default position of the clamp Air Bag Mode Setting (Air Bag specification) Needle bar upper stop position setting

Summary of Contents for SPS/E-5050 Series

Page 2: ......