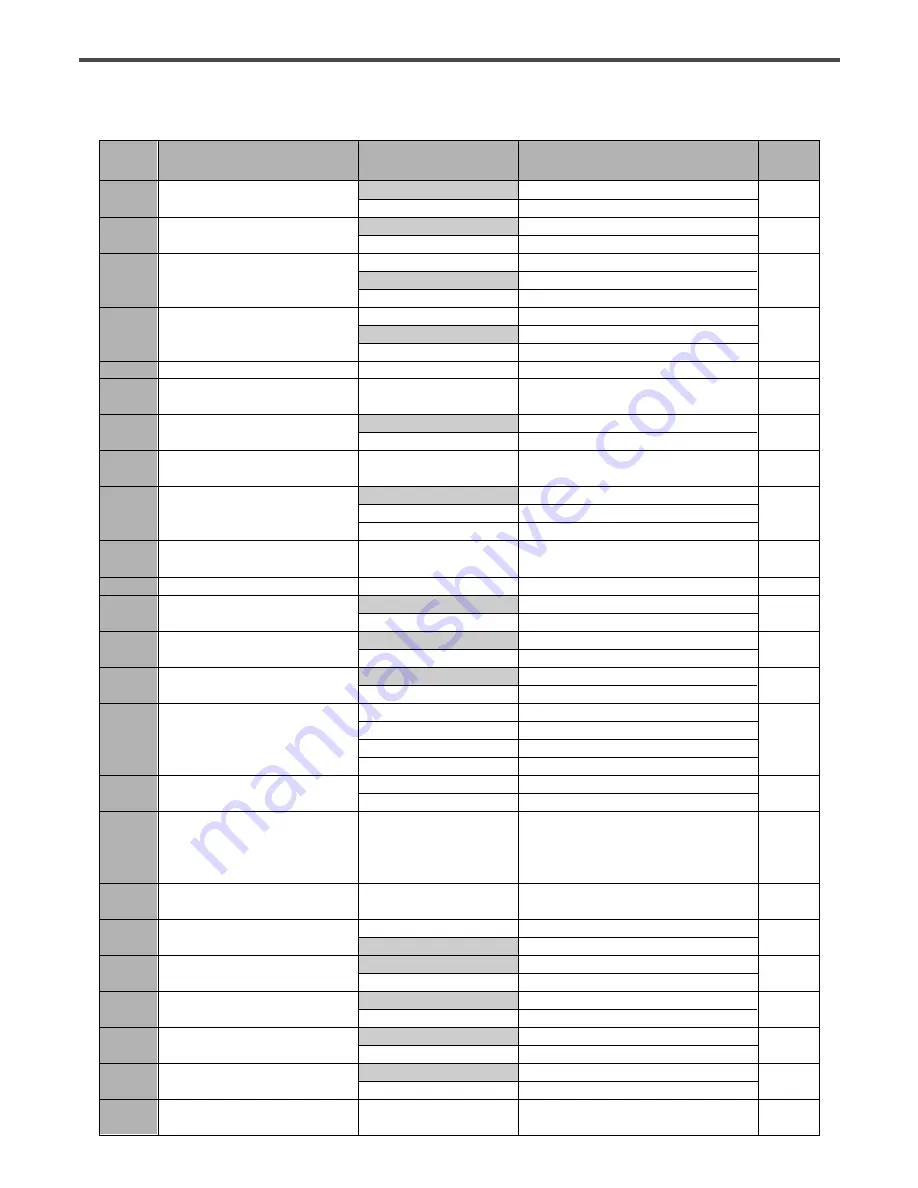

66

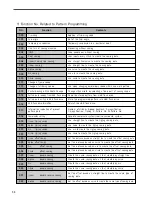

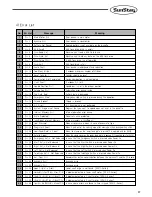

NO.

Function name

Contents

Explanation and factory-installed setting value

Unit

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

Extended I/O board setting

Design preview setting (For Graphic Op

use only.)

Upper/Lower shaft origin search motion

setting

Head up/down setting

Oil spray time setting

Oil stray frequency setting

Upper thread holder setting

Upper thread holder's needle thread

holding time setting

Needle cooling setting

Needle cooling time setting

Needle cooling off time cycle setting

Trimming method setting

Setting the head sensor

Clamp Sensor Setting

Barcode origin point selection

Set barcode Type

Setting the pneumatic trimmer entry

angle

Set up the entry angle of pneumatic

upper thread holder

Set up the presser stepped pulley motor

Setting the opening of the thread

release device for jump section

Setting a lock to the program mode

Setting the default position of the clamp

Air Bag Mode Setting

(Air Bag specification)

Needle bar upper stop position setting

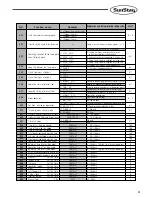

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

1) JOB_SETUP

2) JOB_READY

3) JOB_TRIM

1) HEAD_DOWN

2) HEAD_UP

3) JUMP_HEAD

4

5

1) DISABLE

2) ENABLE

1

1) NORMAL

2) TIMER

3) DISABLE

4

5

1) STANDARD

2) UPER TRIM

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

1) B_ORG_PNT_1

2) B_ORG_PNT_2

3) B_ORG_PNT_3

4) B_ORG_PNT_4

1) DATALOGIC

2) LEUZE BLC 22

0。~50。

0。~100。

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

1) DISABLE

2) ENABLE

1) REF UP

2) REF DOWN

1) DISABLE

2) ENABLE

0~360[degree]

Not used.

Use the extended I/O board.

Not used.

Give a preview of saved designs.

Does not search the upper/lower shaft origin.

Search the upper/lower shaft origin.

Search the origin after trimming.

Does not move up the head.

Move up the head.

Move up the head during the jump motion.

Set the oil spray time (00~10 x 4 [ms]).

This function is to set the cycle of ending oil

spraying motion.(00~50 [sec])

Not used

The thread holder function used after trimming

Set the time the thread holder holds the thread of

the needle after trimming (00~20ms).

The needle cooling function is enabled during sewing.

The function is enabled according to the methods set by user.

Not used

This function is to set the air spraying time to

cool off the needle.(000~100ms).

Set the needle cooling off time cycle.

Trim both the upper and lower threads.

Trim the lower thread only.

Not used.

Used.

Does not detect the clamp sensor.

Detect the clamp sensor.

Set the barcode origin point 1.

Set the barcode origin point 2.

Set the barcode origin point 3.

Set the barcode origin point 4.

DATALOGIC

LEUZE BLC 22

By nature of the device or sewing materials, some

difference is found in the trimmers entry angle. A

user can adjust the trimmer blade entry angle by

using parameters.

A user can adjust the motion angle of the upper

thread holder after setting the trimmer entry angle.

Not used (default value)

Not use the pressure foot stepped pulley motor (use the air-compressed wiper)

Use the pressure foot stepped pulley motor (Factory shipment state)

Used

The function is disabled (default).

In use

The function is disabled (default).

In use

Not use the Air Bag Mode (Factory shipment state)

Use the Air Bag Mod

The value can be set at the range of 0~360。

(Default value: 97。)

4[ms]

1[sec]

1[ms]

1[ms]

1[ms]

1[。]

Summary of Contents for SPS/E-5050 Series

Page 2: ......