14

7.6

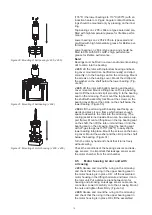

Wear plate on J 205 and J 405

(Figure 20)

J 205:

Lye the oil casing/wear plate down and take out

the stud bolts holding the wear plate. Remove the wear

plate and check the condition if it must be replaced.

Also check the condition of the oil casing.

J 405:

Lye the oil casing /wear plate down. The stud

bolts can be left on the oil casing if condition is OK. Re

-

move the wear plate and check the condition if it must

be replaced. Also check the condition of the oil casing.

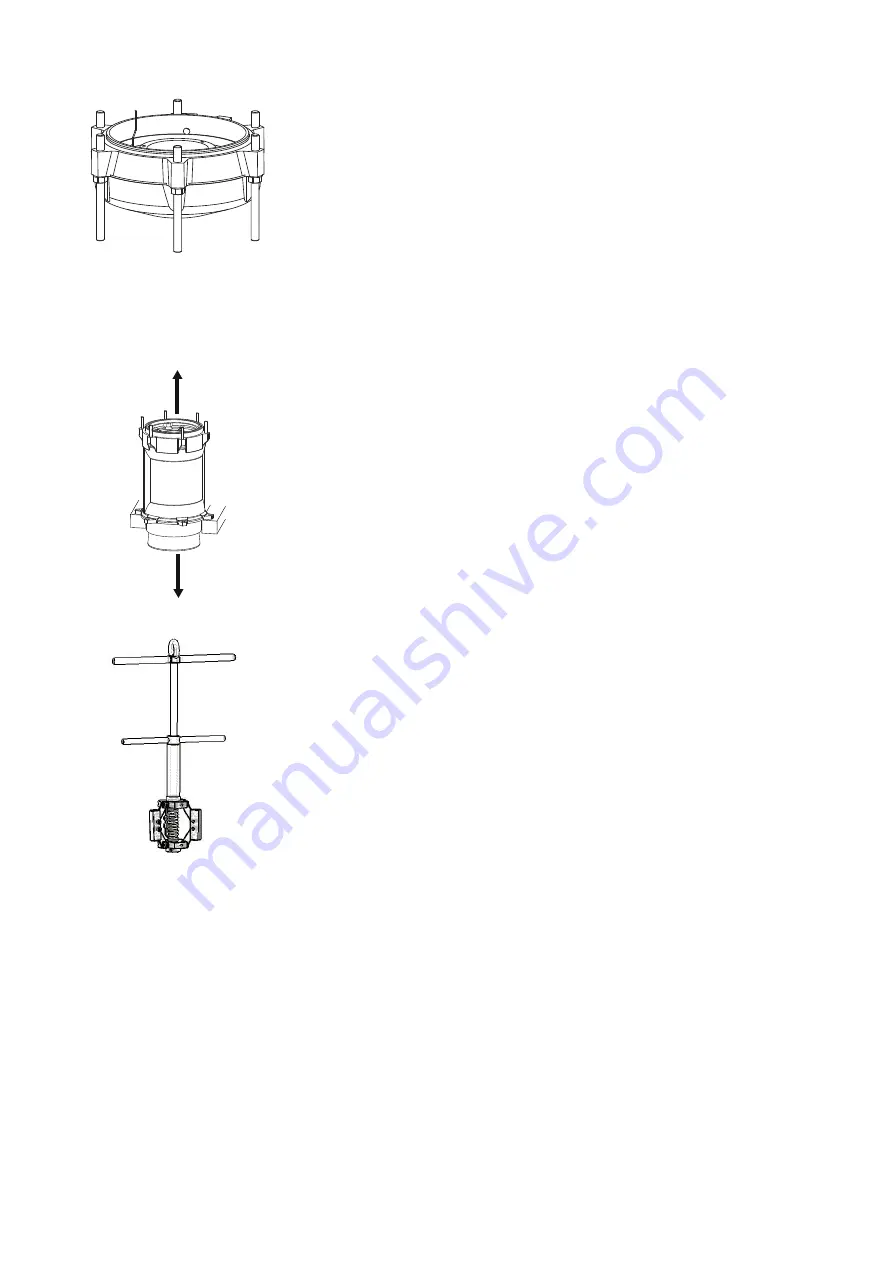

8

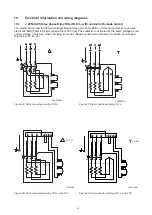

Exchange of stator

8.1

Removal of stator

(Figure 21, 22)

J 205:

Keep the lifting chain mounted on the motor

housing. Put it standing upright. Dismantle the terminal

plate completely.

J 405:

Dismantle the upper motor part/bearing bracket

from the motor housing completely and mount a lifting

chain on the motor housing to secure it with the lifting

crane. Put it standing upright.

J 604:

Mount the lifting eye bolts back on the motor

housing and put the motor housing upright. Dismantle

the terminal plate completely.

Unscrew the stator lock key inside the motor housing

just below the stator (from serial no 60400400).

For all models:

When contactor/terminal plate/upper bearing bracket

has been removed together with all cable seals, ar-

range motor cables well folded together to smoothly fol-

low when the stator is released from the motor housing.

Put the motor housing on distance pieces.

Heat the motor housing with two LP gas flames (Large

propane burner) at the stator laminations and down-

wards until the temperature of about 250ºC (482ºF) is

reached or till the stator starts to fall out.

Then lift the motor housing up smoothly to make sure it

is released from the stator. If necessary tap the motor

housing with a rubber hammer in order to release the

stator. Lift the motor housing up away from the stator.

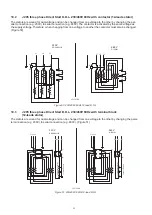

A stator lifting tool may be used for an alternative way

to lift out the old stator from the motor housing. Check

section 11 for part No. (Figure 22)

Clean the motor housing and check for damages, par-

ticularly on the sealing surfaces and in the upper bear-

ing seat.

Remove the o-ring in the upper bearing seat. If damag-

es cannot be corrected, the housing must be rejected.

Note!

Do not use a welder as a burner as this can cause

damages on the motor housing.

Figure 20: Removal of wear plate (J 205, J405)

Figure 21: Removal of stator

Figure 22: Stator lifting tool

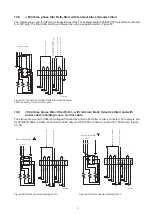

Summary of Contents for J 205

Page 30: ...30 11 Sectional drawing Tools J 205 ...

Page 31: ...31 J 405 ...

Page 32: ...32 J 604 ...

Page 37: ...37 ...