Troubleshooting Guides

Integrated

(700-

3

BASE)

Series

8-16

#3758424 - Revision B - December, 2005

700BR-3

X” vacuum to X psi

XX psi to XXX psi

700BF/I-3

3” vacuum to 2 psi

90 psi to 120 psi

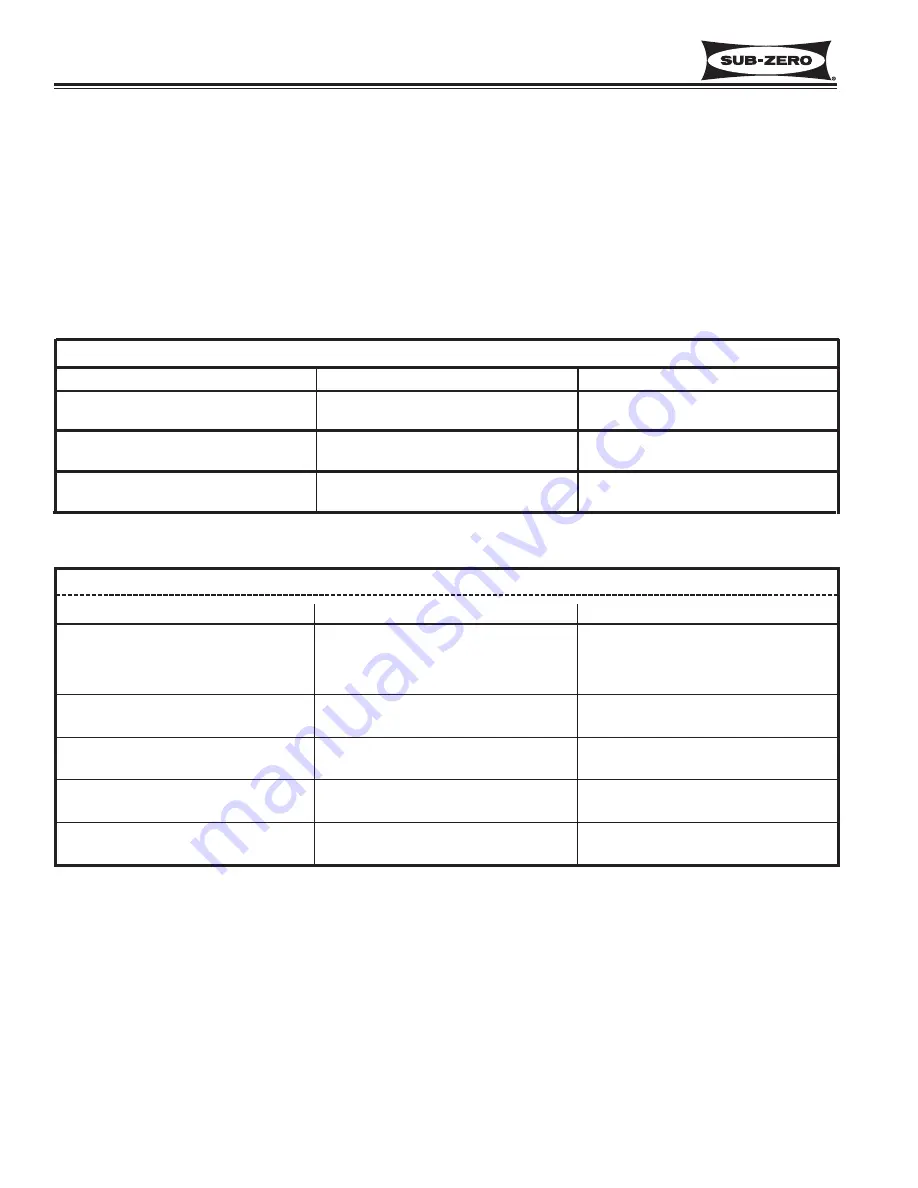

SEALED SYSTEM TROUBLESHOOTING / DIAGNOSTICS TABLES

Before tapping into the sealed system to check pressures, see General Troubleshooting Guide, taking note of prob-

lems “A” through “J”, and if applicable, be sure to reference the “Pointers” in the first column. By initiating Diagnostic

Mode and observing evaporator temperatures, it may be determined unnecessary to tap the sealed system. If need-

ed, the table on the following page provides a quick reference for temperature/pressure correlation.

NOTE:

If entering the sealed system to check pressures, always use solder-on process valves. Do NOT use bolt-

on process valves as they are prone to leak.

NOTE:

Whenever servicing the sealed system, the high-side filter-drier must be replaced.

NORMAL OPERATING PRESSURES

PRESSURE INDICATIONS

If low-side pressure is

NORMAL

LOW

LOW

HIGH

HIGH

& high-side pressure is

NORMAL

LOW

HIGH

LOW

HIGH

possible problem is

MECHANICAL

(see General Troubleshooting Guide)

LEAK

RESTRICTION

INEFFICIENT COMPRESSOR

OVER CHARGE

Model

Normal Low-Side Pressures

Normal High-Side Pressures

700BC/I-3

3” vacuum to 2 psi

90 psi to 120 psi

Summary of Contents for 700-3 BASE

Page 2: ......

Page 12: ...Installation Information Integrated 700 3 BASE Series 2 4 3758424 Revision B December 2005 ...

Page 40: ...Electronic Control System Integrated 700 3 BASE Series 3 28 3758424 Revision B December 2005 ...

Page 48: ...Sealed System Information Integrated 700 3 BASE Series 4 8 3758424 Revision B December 2005 ...

Page 52: ...Airflow Fan Blade Spacing Integrated 700 3 BASE Series 5 4 3758424 Revision B December 2005 ...

Page 58: ...Icemaker Information Integrated 700 3 BASE Series 6 6 3758424 Revision B December 2005 ...

Page 114: ...Wire Diagrams Schematics Integrated 700 3 BASE Series 10 10 3758424 Revision B December 2005 ...