6

OF INCREASED LEVELS OF CARBON MONOXIDE GAS

IN EXCESS OF SAFE LIMITS WHICH COULD RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

You should contact your gas supplier for any specific changes

which may be required in your area.

As elevation above sea level is increased, there is less

oxygen per cubic foot of air. Therefore, the heater input

rate should be reduced at high altitudes for satisfactory

operation with the reduced oxygen supply. Failure to make

this reduction would result in an overfiring of the heater

causing sooting, poor combustion and/or unsatisfactory

heater performance.

Ratings specified by manufacturers for most appliances

apply for elevations up to 2000 feet (610m). For elevations

above 2000 feet (610), ratings must be reduced at the rate of

4% for each 1000 feet (305m) above sea level. For example,

if a heater is rated at 120,000 Btuh (35 kWh) at sea level,

to rate the heater at 4000 feet (1219m), you subtract 4

(once for each thousand feet) x .04 (4% input reduction) x

120,000 (original rating) from the original rating. Therefore,

to calculate the input rating at 4,000 feet (121.9m): 4 x

.04 x 120,000 =19,200 Btuh (5.6 kWh), 120,000 (35 kWh)

- 19,200 (5.6 kWh) = 100,800 Btuh (29.4 kWh). At 6000

feet (1829m) the correct input rating should be 91,200 Btuh

(26.7 kWh).

The input reduction is primarily achieved by reducing the size

of the main burner orifices. To do this, the main burner orifices

require replacement with orifices sized for the particular installation

elevation. Correct orifice sizing and parts may be obtained from

State Water Heaters. When ordering, be sure to state the model

number and the altitude of the location where the water heater

is being installed.

Upon completion of derating of the heater, adjustment to the

gas pressure regulator may be required. See CHECKING THE

INPUT section in this manual for inlet and manifold pressure

requirements.

Also due to the input rating reduction required at high altitudes,

the output rating of the appliance is reduced and should be

compensated for in the sizing of the equipment for application.

FEATURES

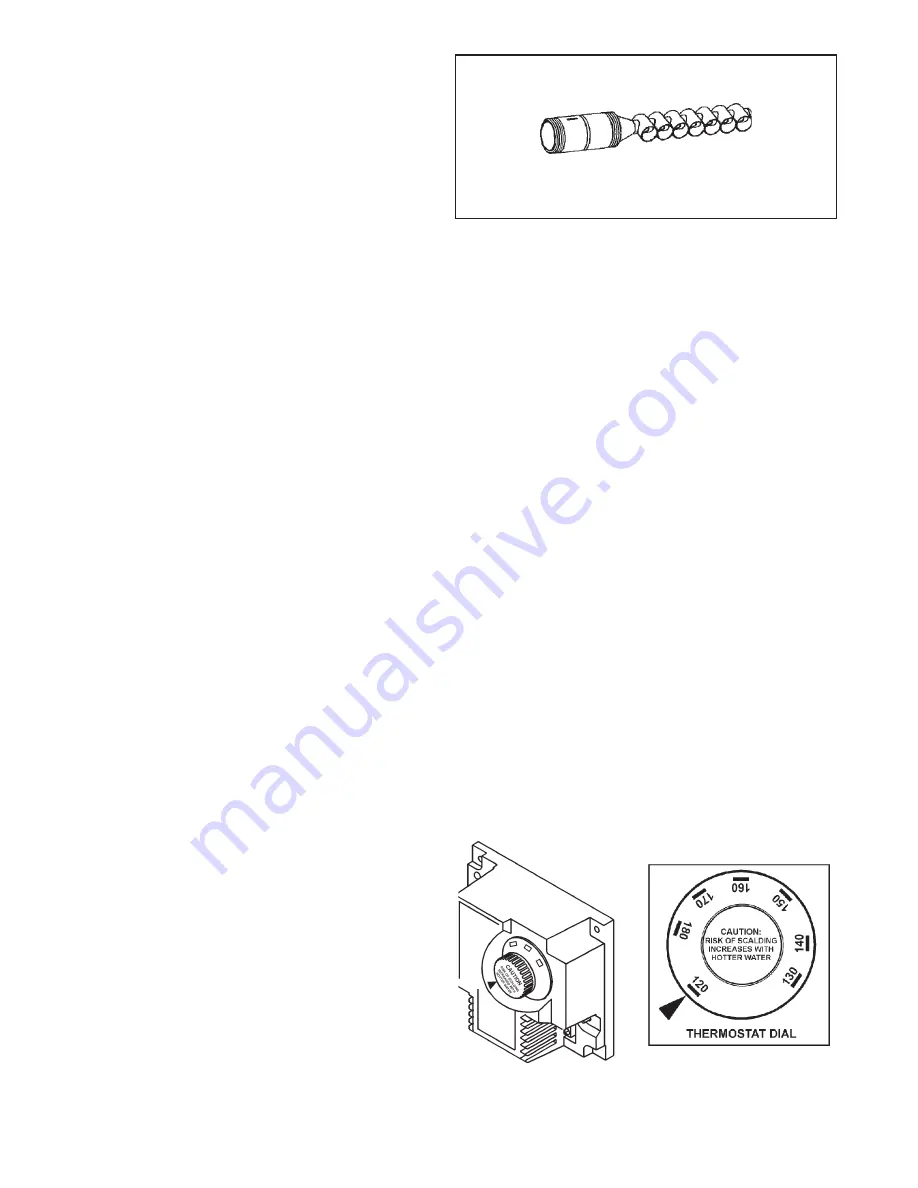

SELF-CLEANING HYDRO CANNON

These units include a self-cleaning hydro cannon installed

in the front water inlet. See figure 2. The hydro cannon

must be oriented correctly for proper function. There is a

marked range on the pipe nipple portion of the hydro cannon,

that must be aligned with the top of the inlet spud. A label

above the jacket hole has an arrow that will point to the

marked portion of the pipe nipple if the orientation is correct.

If the arrow does not point within the marked range on the

pipe nipple, adjust the pipe nipple to correct. A pipe union is

supplied with the hydro cannon to reduce the probability of

misaligning the hydro cannon accidentally while tightening the

connection to the inlet water supply line. Improper orientation

of the hydro-canon can cause poor performance of the heater

and can significantly reduce outlet water temperatures during

heavy draws.

NOTE: The inlet tube may have 1, 3 or 7 cross-tubes.

FIGURE 2

For proper function, the hydro cannon must be oriented correctly.

There is a marked range on the pipe nipple that must be aligned

with the top of the inlet spud (check for label on the appliance) to

assure proper orientation. Please check to confirm that the marked

range is in alignment with the top of the spud. A pipe union is

supplied with the hydro cannon to help eliminate the possibility of

changing the orientation by accidentally over-tightening the inlet

supply line. Improper orientation of the hydro cannon may cause

temperature build-up issues or spells of colder than usual water

temperatures.

HIGH LIMIT SWITCH

The digital thermostat (Fig. 3) contains the high limit (energy cutoff)

sensor. The high limit switch interrupts main burner gas flow should

the water temperature reach 203°F (95°C).

In the event of high limit switch operation, the appliance cannot be

restarted unless the water temperature is reduced to approximately

120°F (49°C). The high limit reset button on the front of the control

then needs to be depressed.

Continued manual resetting of high limit control, preceded by

higher than usual water temperature is evidence of high limit

switch operation. The following is a possible reason for high limit

switch operation:

• A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed the

thermostat setting. The water temperature would continue to

rise until high limit switch operation.

Contact your dealer or service agent if continued high limit switch

operation occurs.

DIGITAL THERMOSTAT

FIGURE 3

Summary of Contents for SBD100199*

Page 35: ...35...