34

English

5-10-1. Cautions

•

Before use, be sure to turn the steel ball with the fingers about the axis of the shaft 2 or 3 times

both clockwise and counterclockwise so that the steel ball rests properly on the end of the shaft.

If this not done, the rust-preventive grease between the steel ball and shaft might cause a

detection error.

Note

•

Do not turn the steel ball more than 180

°

in either direction since a spring is connected to it.

•

Do not pull the steel ball and let it spring back sharply against the end of the shaft.

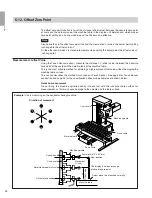

Spring

Dust cover

Give a 180

°

turn

2 to 3 times

(No more than 180

°

)

Shaft

Steel ball

•

Fix the shank to the main spindle in such a way that the shank is not inclined against the axis of

the spindle, since inclination of the shank will cause errors in the measurement.

•

For more precise positioning at the center of the workpiece: Touch the workpiece with the feeler

ball

1

. Then, move the touch sensor to the other side of the workpiece, rotate the shank holder

of the machine through 180

°

and then touch the workpiece

2

. Half the measured value is the

center of the workpiece.

1

2

Rotate the shank holder of the machine

through 180

°

and then touch the workpiece.

Axis of spindle

Center

Workpiece

Axis of spindle