SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Not enough

water in Pulper.

1. Water make up shut-

off valve closed.

2. Low water pressure

3. Faulty operation of

solenoid valve (see

equipment

schematic for

location).

1. Open valve.

2. Increase “POT 1” setting to increase pre-fill. Increase

“POT 2” setting to increase frequency of make-up

water

3. Check for loose electrical connections. If the valve

plunger is stuck or the coil is burned out, replace with

a new valve.

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Too much water

in Pulper.

1. Trough valve open

too far

2. Misadjusted PLC

POT setting.

3. Faulty operation at

valve. (see

equipment

schematic for

location.)

4. Overflow fitting and

line clogged.

1. Throttle down valve to decrease water in pulper and

increase water in extractor (more overflow)

2. The PLC controls the circuit to the solenoid valve. Too

high a setting would tend to hold the solenoid valve

open too long letting too much water into the Pulper.

Adjust POT 2 to correct the problem.

3. Repair or replace solenoid valve.

4. Clean fitting and line.

Summary of Contents for SPC-75S

Page 12: ...Installation ...

Page 16: ...MOUNTING DETAIL OF TROUGH ...

Page 21: ...FOR REFERENCE ONLY ...

Page 22: ...Start Up ...

Page 26: ...Operation ...

Page 32: ...CLEANING YOUR SYSTEM ...

Page 38: ...MAINTENANCE ...

Page 49: ...TROUBLESHOOTING ...

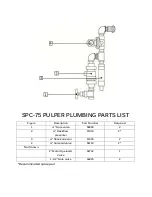

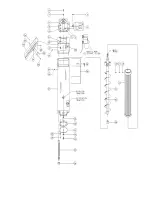

Page 56: ...REPLACEMENT PARTS EXPLODED VIEWS ...

Page 57: ......

Page 60: ......

Page 62: ......