Stenner Chemical Pump

Tube Replacement Instructions

1.

Remove the three cover screws. Lift the cover free.

2.

Set the Feed Rate Dial on #1. Turn the feeder switch

on. Line up the slot in the roller assembly with the lower

or "IN" tube fitting.

3.

With the feeder dial set on #1, lift the tube housing out

of the housing slot and pull it toward the center of the

roller. Start the motor while pulling on the tube until it

comes completely out of the housing. Turn the feeder off.

4.

To install a new tube assembly, position the roller

assembly until the slot is again in line with the "IN" or

suction fitting (See drawing for roller position). Place the

tube fitting into position and push the tube into the slot of

the roller assembly. With the feed rate dial set on #1, start

the motor and feed the tube into the slot as the roller

assembly turns. Be careful of your fingers. Do not force

the tube. Avoid kinds. When the roller assembly slot lines

up with the "OUT" tube housing slot, quickly pull the tube

Summary of Contents for SPC-75S

Page 12: ...Installation ...

Page 16: ...MOUNTING DETAIL OF TROUGH ...

Page 21: ...FOR REFERENCE ONLY ...

Page 22: ...Start Up ...

Page 26: ...Operation ...

Page 32: ...CLEANING YOUR SYSTEM ...

Page 38: ...MAINTENANCE ...

Page 49: ...TROUBLESHOOTING ...

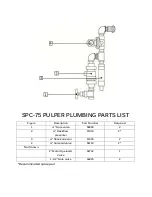

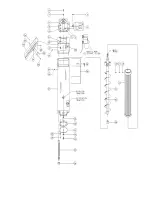

Page 56: ...REPLACEMENT PARTS EXPLODED VIEWS ...

Page 57: ......

Page 60: ......

Page 62: ......