MP PUMP

REMOVAL AND INSTALLATION OF MECHANICAL SEAL or MOTOR

MECHANICAL SEAL

:

1.

Turn off power and lock out machine

2.

Remove (4) 5/16-18 hex nuts from Impeller housing

3.

Remove housing from pump-pak assembly

4.

The impeller will now be visible, take care to NOT place anything in impeller

vanes. This will cause damage to the vane and will not be covered under

warranty.

5.

Loosen 2 bolts holding drive sleeve to motor shaft.

6.

Remove impeller with drive sleeve as an assembly, mechanical seal should come

off with drive sleeve.

7.

Replace mechanical seal. Install with raised carbon face towards motor. Take

care to install straight onto sleeve. Install ceramic disc into adapter seat bore with

polished side up. Take extreme caution to not damage polished side as this will

cause immediate leaks. Ensure seal is seated to bottom of adapter seat bore. If

needed use a wooden dowel and gently tap into place to ensure tight seat into

bore.

8.

Replace impeller assembly back onto motor shaft. Use a light coating of anti-seize

on motor shaft to ensure smooth seating.

9.

Push down onto impeller head using a gloved hand to reach a gap of .030

between the bottom of impeller to top of adapter.

10.

Tighten sleeve clamp while maintaining .030 clearance

11.

Check rotation of impeller to ensure proper seating and gap clearance

12.

If rotation and clearance are ok, then replace housing to adapter

13.

Install (4) 5/16-18 nuts and lock-washers onto studs and tighten to 15-ft.lbs.

14.

Verify that impeller does NOT hit or scrape housing.

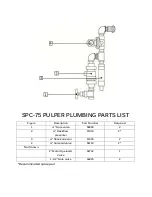

Summary of Contents for SPC-75S

Page 12: ...Installation ...

Page 16: ...MOUNTING DETAIL OF TROUGH ...

Page 21: ...FOR REFERENCE ONLY ...

Page 22: ...Start Up ...

Page 26: ...Operation ...

Page 32: ...CLEANING YOUR SYSTEM ...

Page 38: ...MAINTENANCE ...

Page 49: ...TROUBLESHOOTING ...

Page 56: ...REPLACEMENT PARTS EXPLODED VIEWS ...

Page 57: ......

Page 60: ......

Page 62: ......