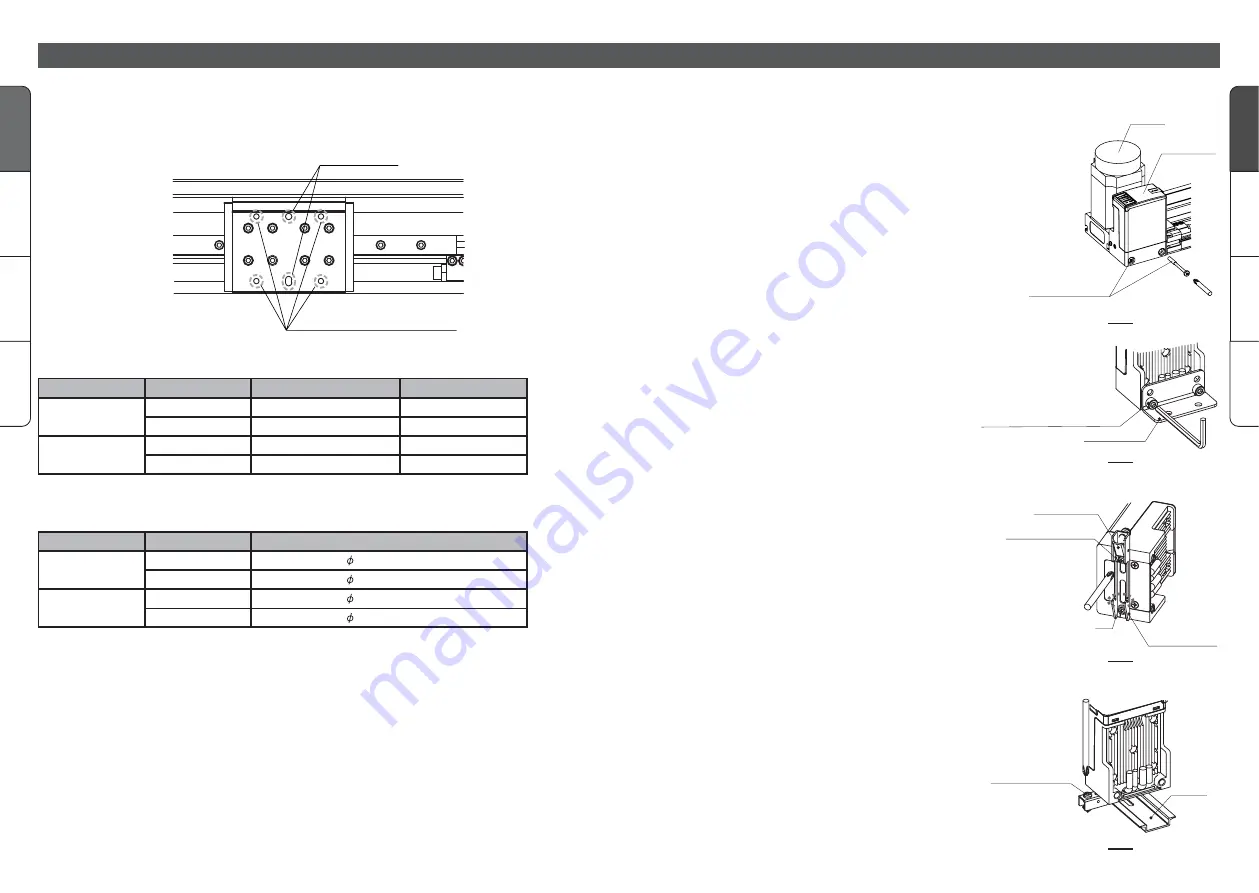

Knock pin hole

9

Gener

al

3 positions

5 positions

Gener

al

8

Gener

al

3 positions

5 positions

Gener

al

Installation (continue)

Installation of work tap

Taps hole to installation of work

Knock pin hole

Precautions for installation

•Do not operate the actuator outside operating temperature range.

•Do not install the actuator in the place which may be used as foot base.

•Keep flatness following mechanical accuracy or equivalent reference for the face where the

actuator is installed.

Also, confirm the flatness is within 0.1/500mm

Installation of work

Use 4 taps on the top of slider for installation of work.

Also, if necessary, utilize knock pin hole as well.

Nominal of actuator

16

25

Threaded hole dimension

M4 depth 7mm

M5 depth 9mm

Effective length

4 to 7mm

5 to 9mm

•Select screw which enables effective length of thread to enter.

Nominal of actuator

16

25

Hole diameter and width of oval hole

( )4 H7 depth 5mm

( )5 H7 depth 5mm

Mounting controller (When controller separated type is used)

Mounting screw (M5)

Tightening torgue 1.3 to 1.4N

•

m

L type bracket

Controller

Motor

Mounting screw

(M4)

Mounting by L type bracket

Mount the optional L type bracket on the main

unit using the two mounting screws M5X8L and

install on the facility using hexagon socket head

cap screws as shown in fig. 2.

Clamp bracket

DIN rail

mount bracket

Mounting screw(M3)

Tightening torgue

0.5 to 0.7N

•

m

A

Mounting by DIN rail bracket

Use set screw to mount optional DIN rail mount

bracket to the body.

When mounting, lower the clamp bracket as in

fig. 3.

Please be noted that some tools may interfere

with clamp bracket.

DIN rail

Tightening torgue

0.4 to 0.6N

•

m

Clamp screw(M4)

When setting to DIN rail, place A of fig. 3 into

DIN rail.

While pushing it, fix it by the clamp of screw in fig.

4.

Inadequate pushing may cause falling of parts.

Direct mounting

Use M4 mounting screw shown in fig. 1 or M5

tap hole to mount the controller.

How to remove controller

Loosen M4 mounting screw shown in fig. 1 and

remove the controller.

fig. 1

fig. 2

fig. 3

fig. 4

Model

E-MY2C

E-MY2H

16

25

M5 depth 9mm

M8 depth 12mm

5 to 9mm

8 to 12mm

E-MY2HT

Model

E-MY2H

16

25

( )5 H7 depth 5mm

( )6 H7 depth 8mm

E-MY2HT

•A knock pin is attached only to E-MY2H and E-MY2HT.