15

2917

14

2020

-

PJC 211 & 212

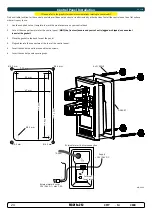

Proportional Thruster Display

MC_0053

Status indicators for bow

thruster. (Port bow thruster

in a dual bow thruster setup).

Runtime indicator will be shown here

in a single DC electric bow thruster

setup.

Status indicators for stern thruster.

(Port bow thruster in a dual stern

thruster setup)

Runtime indicator will be shown here

in a single DC electric stern thruster

setup.

Status indicators for starboard

bow thruster. Only shown in

a dual bow thruster setup.

Battery indicator will be

shown here in a single DC

electric bow thruster setup.

Status indicators for starboard

stern thruster. Only shown in a

dual stern thruster setup.

Battery indicator will be shown

here in a single DC electric stern thruster

setup.

BOW

STERN

BOW-STB

STERN-STB

Examples of display view for different panels applications:

PJC211:

DC Electric Bow thruster

PJC221:

Hydraulic Bow thruster

PJC221:

AC Electric Bow thruster

PJC212:

DC Electric Bow thruster

DC Electric Stern Thruster

PJC222:

Hydraulic Bow thruster

Hydraulic Stern Thruster

PJC222:

AC Electric Bow thruster

Hydraulic Stern Thruster

PJC211:

DC Electric Stern thruster

PJC212:

Dual DC Electric Bow thrusters

Dual DC Electric Stern thrusters

PJC222:

Dual Hydraulic Bow thrusters

Dual Hydraulic Stern thrusters

PJC222:

Dual AC Electric Bow thrusters

Dual AC Electric Stern thrusters

PJC221:

Dual AC Electric Bow thrusters

PJC221:

Dual Hydraulic Bow thrusters

PJC221

PJC222

PJC211

PJC212