21

2917

14

2020

-

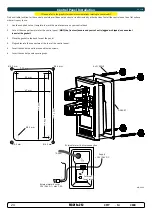

PJC 211 & 212

PHC-3

Fault Codes

MC_0117

Fault Code

Description

Cause

Action

10500.0.10

PHC Oil Level - Level Low

Hydraulic oil level is low

"-Limit use of thruster

-Inspect hydraulic oil level

-Check system for leaks and refi ll hydraulic oil"

10500.0.13

PHC Oil Level - Open Circuit

Analog oil level sensor open circuit

"-Sensor not connected or wire break.

-Verify sensor type in parameter 0201

-Disconnect sensor and measure that sensor resistance value is in

range 0-180ohm."

10501.0.11

PHC Oil Temp - Level High

Oil temperature higher than 75°C (167°F)

"-Limit use of thruster to prevent temperature to rise.

-Check if cooling pump is running and there is cooling water flow.

-Inspect seawater fi lter

-Verify that cooling pump is enabled in parameter 0301"

10501.0.13

PHC Oil Temp - Open Circuit

Analog oil temp sensor open circuit

"-Sensor not connected or wire break.

- Disconnect sensor and measure that sensor resistance value is in

range 104ohm-147Kohm

-Wrong sensor is defi ned in parameter 0201"

10501.0.16

PHC Oil Temp - Short Circuit

Analog oil temp input short circuit

"-Input shorted to GND, check wiring/sensor

-Disconnect sensor and measure that sensor resistance value is in

range 104ohm-147Kohm"

10502.0.13

PHC Stabilizer Pressure - Open Circuit

Stabilizer pressure sensor open circuit

"-Sensor not connected or wire break.

-System incorrectly confi gured with stabilizer, parameter 1001

-Replace sensor"

10502.0.16

PHC Stabilizer Pressure - Short Circuit

Stabilizer pressure sensor short circuit

"-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor"

10502.0.19

PHC Stablizier Pressure - Under Limit

Stabilizer pressure has dropped below 20bar.

"-Check accumulator charge pressure

-Check PTO pressure (if PTO powered)

-Check system for oil leaks

-Check generator power supply to the VFD (is VFD motor speed

maximum when pressure alarming low)"

10502.0.20

PHC Stablizier Pressure - Over Limit

"Stabilizer pressure is higher than:

parameter 1013 PTO OVER-PRESSURE FAULT LEVEL running

from PTO (FW V1.029 an older, set point + 30bar running

from PTO)

or set point + 15bar running from AC motor"

"-Check Parameter 1013 PTO OVER-PRESSURE FAULT LEVEL

-Check PTO pressure setting

-Check accumulator charge pressure

-Check unload valve operation"

10502.0.26

PHC Stablizier Pressure - VALUE MAX

Stabilizer pressure reached sensor max value.

"-Check that correct sensor is fi tted

-Check that sensor range parameter 1010 match the sensor

-Check PTO pressure setting"

10502.0.200

PHC Stablizier Pressure - Timeout

Stabilizer pressure has not reached 60% of set point parame-

ter 1003 after 30sec.

"-Check pump feed shutoff valve.

-Check PTO pressure (if PTO powered)

-Check system for oil leaks"

10503.0.13

PHC System Pressure - Open Circuit

System pressure sensor open circuit

"-Sensor not connected or wire break.

-Verify system pressure, parameter 0104"

10503.0.16

PHC System Pressure - Short Circuit

System pressure sensor short circuit

"-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor"

10504.0.13

PHC AI 1 - Open Circuit

Analog Input 1 (4-20mA) sensor open circuit

-Sensor not connected or wire break.

10504.0.16

PHC AI 1 - Short Circuit

Analog Input 1 (4-20mA) sensor short circuit

"-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor"

10505.0.13

PHC AI 2 - Open Circuit

Analog Input 2 (4-20mA) sensor open circuit

-Sensor not connected or wire break.

10505.0.16

PHC AI 2 - Short Circuit

Analog Input 2 (4-20mA) sensor short circuit

"-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor"

10508.0.13

PHC DOUT AC PUMP UNLOAD - Open Circuit

AC Pump Unload valve open circuit

"-Check for open circuit, power consumption < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001"

10508.0.51

PHC DOUT AC PUMP UNLOAD - Current High

AC Pump Unload valve current higher than 4.0A

-Check wires and connections for short circuit

10509.0.13

PHC DOUT ACCUMULATOR DUMP - Open

Circuit

Accumulator Dump valve open circuit

"-Check for open circuit, power < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001"

10509.0.51

PHC DOUT ACCUMULATOR DUMP - Current

High

Accumulator Dump valve current higher than 4.0A

-Check wires and connections for short circuit

10510.0.13

PHC DOUT STABILIZER - Open Circuit

Stabilizer valve open circuit

"-Check for open circuit, power consumption < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001"

10510.0.51

PHC DOUT STABILIZER - Current High

Stabilizer valve current higher than 4.0A

-Check wires and connections for short circuit

10511.0.13

PHC DOUT COOLING PUMP HYDRAULIC - Open

Circuit

Hydraulic Cooling Pump valve open circuit

"-Check for open circuit, power consumption < 5.0 Watt

-Wrong cooling pump confi gured, parameter 0301"

10511.0.51

PHC DOUT COOLING PUMP HYDRAULIC -

Current High

Hydraulic Cooling Pump valve current higher than 4.0A

-Check wires and connections for short circuit

10512.0.13

PHC DOUT LS DUMP - Open Circuit

LS-Dump valve open circuit

"-Check for open circuit, power consumption < 5.0 Watt

-System wrong confi gured with thrusters, parameter 2001 or

2101"

10512.0.51

PHC DOUT LS DUMP - Current High

LS-Dump valve current higher than 4.0A

-Check wires and connections for short circuit

10513.0.51

PHC DOUT PUMP #2 - Current High

Pump #2 valve current higher than 4.0A

-Check wires and connections for short circuit

10514.0.13

PHC DOUT 5 - Open Circuit

Digital Output 5 is confi gured as crossover and output is open

circuit

"-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0505"

10514.0.51

PHC DOUT 5 - Current High

Digital Output 5 current higher than 4.0A

-Check wires and connections for short circuit

10515.0.13

PHC DOUT 6 - Open Circuit

Digital Output 6 is confi gured as crossover and output is open

circuit

"-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0506"

Alarm Descriptions

MC_0053

1. PPC520, PPC820, PPC800, PPC840

2. Buzzer is only activated when any device is sending thrust on the S-link bus.

"Err.

No."

Errors shown in display "Auto

Reset"

"Ext. buzzer

activation at

Alert Level"

Description

Action

19

Actuator Fault

2

(

²

)

, 3

Actuator not getting any power

"Check actuator connection or power

to actuator. Reset alarm in alarm

menu on PJC 211/212/221/222 or

recycle power."

20

Pos.Sensor Fault

2

(

²

)

, 3

Retract position sensor fail

Check position sensor cables and for

sensor damage.

21

In Service Mode

Yes

2

(

²

)

, 3

"Retract controller in service mode. Switch

no. 4 is ON."

Check dip switch setting on retract

control box.

22

High Oil Temp

Yes

1, 2

(

²

)

, 3

"Hydraulic oil temperature is higher than

75°C /167°F."

"Stop running and wait for

temperature to drop.

Check if cooling pump is running."

23

Low Oil Level

1, 2

(

²

)

, 3

Hydraulic oil level is to low

Fill more hydraulic oil to the

hydraulic tank.

24

Warning Return Filter

Yes

2

(

²

)

, 3

Return fi lter element required

replacing.

25

Warning Pressure Filter

Yes

2

(

²

)

, 3

Pressure fi lter element required

replacing.

26

Warning High Speed

Yes

1, 2

(

²

)

, 3

"WARNING! High Speed.

Stabilizer not active!"

27

Stabilizer Fault

Yes

1, 2

(

²

)

, 3

Any Stabilizer alarm.

See stabilizer panel for more info.

28

AC Motor Overtemp

Yes

1, 2

(

²

)

, 3

"Hydraulic AC motor power pack overtemp.

Higher than

120°C/248°F."

Stop running and wait for

temperature to drop.

29

AC Motor Sensor Fail

2

(

²

)

, 3

"Hydraulic AC motor power pack temp

sensor open circuit"

Check sensor cables.

30

Temperature Warning

Yes

2

(

²

)

, 3

(

²

)

High temperature warning.

Warns that the motor temperature is

getting high.

31

Motor Overtemp

Yes

1, 2

(

²

)

, 3

High temperature Alarm.

See SAC manual for more details.

32

VFD Warning

Yes

2

(

²

)

, 3

There is an warning from VFD.

Check VFD for more details.

33

VFD Not Ready

Yes

2

(

²

)

, 3

The VFD is not ready.

Check VFD for more details.

34

VFD Fault

1, 2

(

²

)

, 3

VFD has an Alarm.

Check VFD for more details.

35

Warning Low Voltage

Yes

2

(

²

)

, 3

(

²

)

Low motor voltage warning when motor is

running.

12V thruster below 9.30V

24V thruster below 17.50V

36

Not Calibrated

Yes

2

(

²

)

, 3

Shaft Not Calibrated

See manual for how to calibrate.

37

VFD Com. Fault

2

(

²

)

, 3

No Modbus communication with VFD

Check VFD Modbus cables and

power.

38

Cooling Fan Fault

2

(

²

)

, 3

Cooling fan stopped running, or running

too slow

Device must be sent for service

39

Interlock

2

(

²

)

, 3

S-link communication between PPC and

retract controller are missing

-Check PPC or retract controller has

power.

-Check S-Link connections to PPC

and retract controller.

-Check if not PPC or SR150000/

SR61242 is wrongly setup as SRP or

SRVP/SRLP.