19

2917

14

2020

-

PJC 211 & 212

Alarm Descriptions

MC_0053

1. PPC520, PPC820, PPC800, PPC840

2. Buzzer is only activated when any device is sending thrust on the S-link bus.

"Err.

No."

Errors shown in display "Auto

Reset"

"Ext. buzzer

activation at

Alert Level"

Description

Action

1

Motor Overcurrent

2

(

²

)

, 3

Motor current too high.

"Thruster must be serviced by

authorized personnel, reset or power

OFF/ON PPC

(

¹

)

."

2

Motor Overtemp

Yes

2

(

²

)

, 3

"Motortemp has been over

120°C/248°F."

Motor cool down below 110°C /230°F.

3

Controller Overtemp

2

(

²

)

, 3

"PPC

(

¹

)

temp has been over

80°C/176°F."

PPC

(

¹

)

cool down below 45°C/113°F.

4

Controller Overtemp

2

(

²

)

, 3

"SR150000 temp has been over

80°C/176°F."

SR150000 cool down below 45°C

/113°F.

5

Low Voltage

2

(

²

)

, 3

Low motor voltage alarm when motor

is running.

12V thruster below 8.00V

24V thruster below 12.00V

Recharge battery, reset or power OFF/

ON device.

6

Thermoswitch

Yes

2

(

²

)

, 3

Thermo switch input is activated and

there is an open circuit.

The thruster needs to cool down before

operating again.

7

IPC Error

2

(

²

)

, 3

Motor relay fault

"Turn off thruster battery main switch.

Thruster must be serviced by authorized

personnel."

8

Critical Error

2

(

²

)

, 3

PPC

(

¹

)

output fail

PPC

(

¹

)

must be sent for service.

9

Low Motor Current

2

(

²

)

, 3

Thruster uses no power

Check thruster connections or motor

dead!

10

Motor Contactor

2

(

²

)

, 3

No current on motor relay coil.

Check motor relay connections, short

circuit or relay dead!

11

System Error

2

(

²

)

, 3

Fatal error

Device must be serviced by authorized

personnel

12

No Communication

2

(

²

)

, 3

No communication with device

Check S-Link cables and power

connections.

13

Motor Temp Sensor

2

(

²

)

, 3

Motor temperature sensor fail

Check for an open circuit on the temp

sensor on the motor

14

Supply Voltage Fault

2

(

²

)

, 3

No power

Check power connections

15

Fuse Blown

2

(

²

)

, 3

Fuse blown

Replace fuse or check if main cable from

battery and main cable to thruster has

been switched

16

Manual Override

Yes

2

(

²

)

, 3

Main switch manually overridden

Pull main switch

17

Motion OUT Fault

2

(

²

)

, 3

Retract obstructed while deploying

Turn off all panels. Go for lower speed/

deeper water and retry.

18

Motion IN Fault

2

(

²

)

, 3

Retract obstructed while retracting

Turn panel on and manually override

main switch. Remove obstruction and

try again.

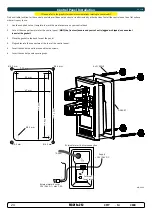

MENU System

MC_0053

LANGUAGE

LANGUAGE

•

Choose language by moving joystick:

English, Norwegian, German, French,

Spanish, Italian and Danish.

•

Press the button below

to set

the language to the highlighted menu

entry. A star (*) on each side indicates

the language set.

DEFAULT

DEFAULT SETTINGS

•

Reset all settings to factory default

- follow instructions on screen

•

Press the button below

to confi rm reset

•

The following parameters/values will be set to the

factory settings:

Language = English

Backlight Level = 5

Backlight Night Colour = Green

Backlight Nightlevel =1

Timer Auto-Off = 05 min

Hold Calibration =70% Bow and Stern

All system devices will be erased from memory.

(Setup procedure must be followed to reconfi gure the system)

STABILIZER

STABILIZER

(Shown only for yachts equipped with a Side-Power Stabilizer system)

Press the button below

to edit the selected parameter.

ON/OFF will start to blink, use joystick to alter value.

Press the button below

to save edited parameter to device.

(Default in systems

with stabilizers)

2. AnySpeed:

•

Values: ON/OFF

•

Switches the zero speed/at

anchor stabilization ON or OFF.

1. Stabilizer:

•

Values: ON/OFF

•

Switches the stabilizer ON or OFF.