67

Troubleshooting

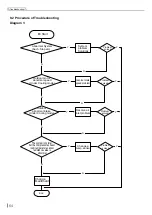

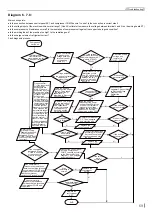

Diagram 4:

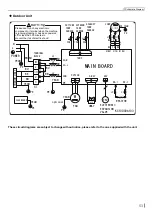

Main test points:

● Check the system pressure is high.

● Check the voltage is low.

Step out problem happen

after power on

Check the

compressor stop

more than 3 mins

Check the compressor wire

COMP(UVW) is connected.Make sure

chronological connection.

Change control

board AP1

Errors declared?

Change

Compressor

End

Connected wires

End

Change

Compressor

Errors declared?

Change control

board AP1

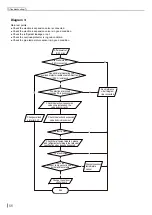

Over fill refrigerant?

The input voltage

setting is normal.

The unit

heat dissipation is

bad.

Step out during the

operation

Check the outside fan

motor is normal.

Check the fan terminals

OFAN is connected.

Change fan motor

capacity C1

Change outside

fan motor

Improve heat dissipation for

unit( such as heat exchanger

clearance strengthen

ventilated

Please recovery the

power to normal voltage

before start

Add the refrigerant by the

technical service manual