Maintenance

5

-18

5

2

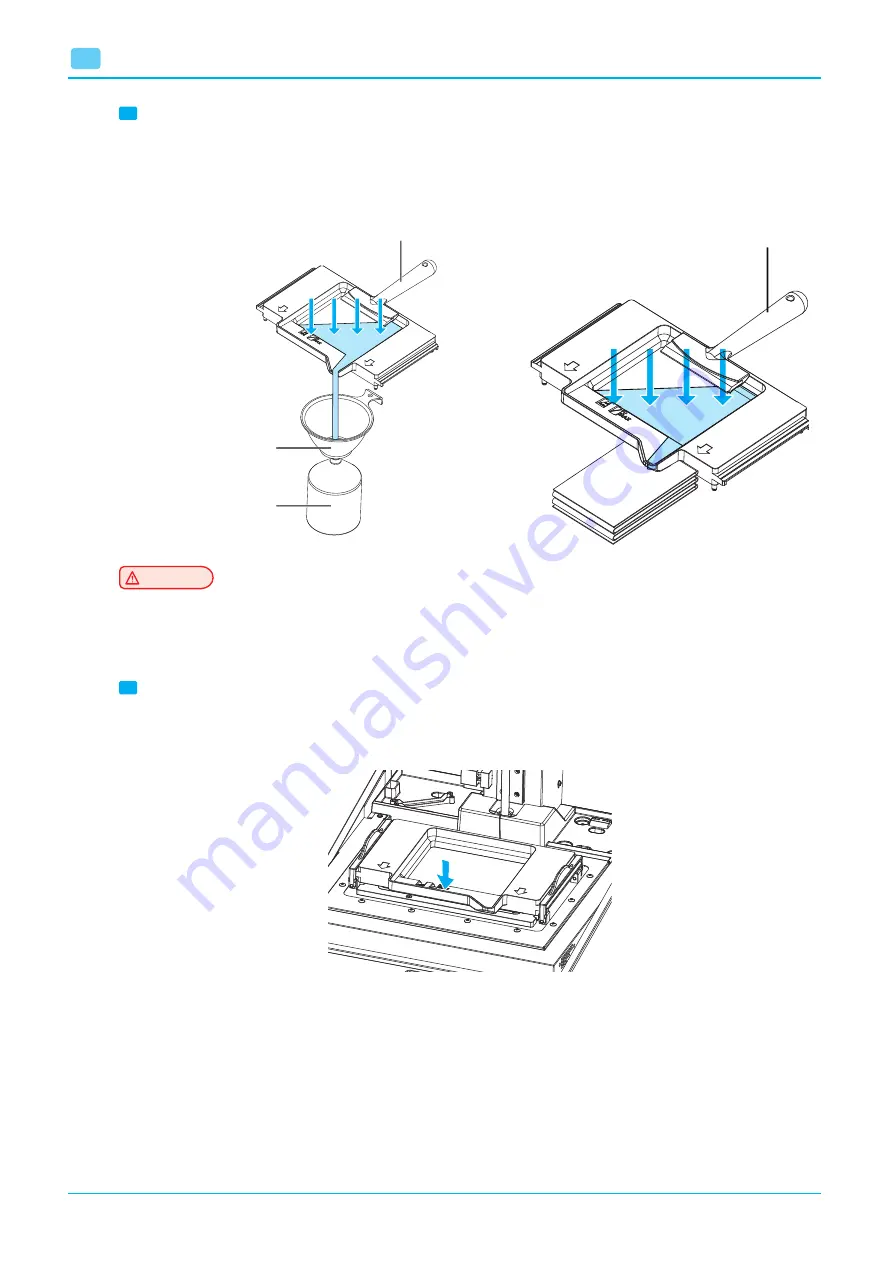

Removing remaining resin

If resin remains in the resin tank, pour all remaining resin through the filter and store them in a bottle.

If resin does not flow down from the resin tank, lean the resin tank onto several layers of waste paper or

paper towel, and use a rubber scraper to scrape down resin. Repeat this procedure.

Cleaning Funnel

Bottle

Rubber Scraper

Rubber Scraper

Caution

- Use a safe bottle made of stainless steel or transparent PE/PP plastic. If not, resin can be pigmented,

or the bottle can melt down and mix with resin.

-

Be careful not to drop or splash resin when pouring.

3

Installing a new resin tank

Install the resin tank in the following order:

①

Place the resin tank between the locking levers.

Summary of Contents for A1SD Series

Page 28: ......

Page 29: ...1 Preparation for Machine Operation Sindoh A1SD Series USER MANUAL ...

Page 40: ......

Page 41: ...2 UI Menu Function Sindoh A1SD Series USER MANUAL ...

Page 92: ......

Page 93: ...3 Printing Sindoh A1SD Series USER MANUAL ...

Page 106: ......

Page 107: ...4 Checking Printed Output Sindoh A1SD Series USER MANUAL ...

Page 117: ...Maintenance 5 Sindoh A1SD Series ...

Page 142: ......