8

GB

7. Preparation

7.1 Setting up the device

Place the device on a dry, level and heat-re-

sistant surface.

7.2 Requirements on the

film/bags

-

You can use tubular film or complete

bags.

-

The film bag must not be wider than

30

|

cm.

-

The film bag must have dots/knobs or

grooves on one side. Smooth film bags

are not suited for sealing.

-

The thickness should be between 0.17

and 0.29 mm (170 - 290

m).

-

When buying the film bag, check the

temperature range it is suited for. The

ideal range is between -20 °C and

+110 °C. Such film bags can be deep-

frozen or boiled. The film supplied is

suitable for this application.

-

You will find those data on the package

of the film or bag.

7.3 Producing a bag

If you use finished bags, these steps do not

apply.

1. Unwind the length of vacuum bagging

tube from the roll that you require for

your bag. Regarding the length of the

bag, remember that a space of approx.

6 cm towards the top should be left af-

ter filling.

2. Use scissors to cut the piece of vacuum

bagging tube as straight as possible.

3. Seal one end of the bag (see “Sealing

bags (without valves)” on page 10).

8. Use

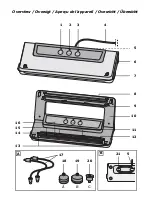

8.1 Overview of the

functions

All functions stop automatically when the

process is complete.

Pressing the function button again can cancel the

process sooner.

WARNING! Risk of material dam-

age!

~

After the sealing and/or vacuuming

process, the device needs to cool down

for at least 80 seconds.

Button

Function

|

1

Start/cancel vacuum-pack-

ing using the connection

|

6

with a vacuum tube

|

17

and

an adapter

|

18

/

19

/

20

|

2

Start/cancel sealing (with-

out vacuum)

|

3

Start/cancel vacuum-pack-

ing and sealing the film bag