7SG11 Argus 8 Commissioning

3 Commissioning tests

3.1 Inspection

Check that the relay has not been damaged in any way since being installed into the panel. Remove

the relay from the case and check that the serial numbers of the relay, the case and the relay cover are

all identical. Check also that the relay is the correct model and that the rating information is correct for

the particular installation.

Ensure that all external connections are tight and that the relay case is solidly bonded to a local earth

point by checking the earthing connection to the case. Replace the relay back into the case and check

that it is fully inserted.

3.2 Insulation

When required, insulation tests to check the relay and associated wiring can be performed using a

500V electronic insulation resistance test set. The wiring may be tested between :-

1. All electrically isolated circuits.

2. All circuits to earth.

Accessible terminals of the same circuit should be connected together and deliberate circuit earthing

links removed for the tests. Normal connections must be restored after testing. Satisfactory values for

the various readings above depend upon the amount of wiring concerned. Where considerable multi-

core wiring is involved a reading of 2.5 to 3.0 M

Ω

can be considered satisfactory. For short lengths of

wiring higher values can be expected. A value of 1.0 M

Ω

or less should not be considered satisfactory

and should be investigated.

We do not recommend a 2KV site pressure test on the secondary wiring with relays connected. If this

has to be carried out then, as above, deliberate earth links must be removed. Note that both the

positive and negative feeds to the relay’s DC/DC converter are earthed via 5KV capacitors and the

leakage current of these capacitors may trip the 2KV pressure test set. Also note that the capacitance

effect of the secondary wiring may give rise to test set calibration errors that give impressed voltages

higher than measured. To avoid this phenomenon, the pressure test set used should have the metering

on the secondary (high voltage) side. Suitable test sets are manufactured by T&R Test Equipment

(Type KV5 – 100).

While performing the tests, HV test voltages should be smoothly increased form zero and smoothly

decreased to zero after the test to avoid arcing and trapped charge.

All Reyrolle relays are comprehensively pressure tested during manufacture.

3.3 Wiring Check

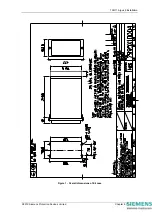

Check that the wiring to the back of the relay is as required by the external connection diagram or the

relevant scheme diagram.

3.4 Auxiliary Supply Check

Before energising the relay check with a multimeter that the dc auxiliary supply voltage is within the

operating range of the relay given in the table below :

Rating (V)

Operating Range (V)

Vaux

24 / 30 / 48

18 – 60

Vaux

110 / 220

88 – 280

Note that the relay can withstand a superimposed ac ripple of upto 12% on the upper limit of the

operative dc voltage range

.

©2010 Siemens Protection Devices Limited

Chapter 7 Page 4 of 12