-61-

Model W1825 (For Machines Mfd. Since 07/15)

SE

RV

IC

E

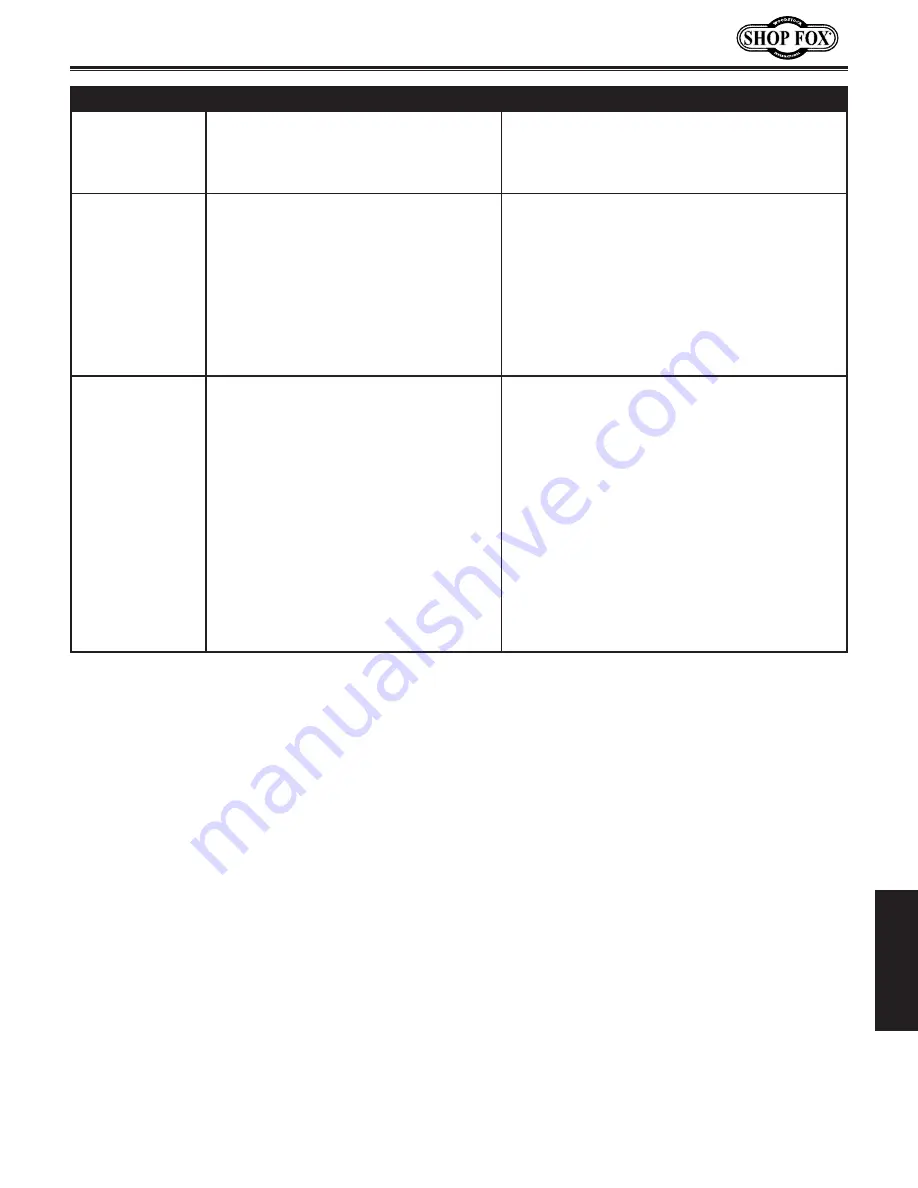

PROBLEM

POSSIBLE.CAUSE

CORRECTIVE.ACTION

Sawdust buildup

inside cabinet.

1. Clogged dust port.

2. Low CFM (airflow) from dust collection

system.

1. Clean out dust port.

2. Repair duct for leaks or clogs, move dust collector

closer to machine, install a stronger dust collec-

tor.

Blade tracks incor-

rectly, or comes off

wheels.

1. Tracking is not adjusted properly.

2. Wheels are not coplanar.

3. Blade tension is too loose.

4. Blade guides need adjustment.

5. Feeding workpiece too fast.

6. Incorrect blade for bandsaw.

7. Blade is bell-mouthed, worn or dull.

8. Rubber tire on wheel is damaged or worn.

1. Adjust tracking (

Page 20).

2. Adjust wheel coplanarity (

Page 54).

3. Increase blade tension (

Page 24).

4. Adjust blade guides (

Page 26).

5. Feed workpiece slower (

Page 34).

6. Install correct blade for machine.

7. Install new blade, and de-tension blade when not in

use.

8. Replace rubber tires.

The cut is crooked,

or the blade wan-

ders (blade lead).

1. The feed pressure is too high or the blade

speed is wrong.

2. The blade tension is low.

3. The blade is dull or damaged.

4. Inadequate blade support.

5. Incorrect blade for application.

6. The blade tracking is wrong.

7. Table is loose.

8. Fence or miter slot out of alignment with

blade.

9. Blade guide alignment at fault.

1. Adjust feed rate and cutting speed as required.

2. Increase the blade tension (

Page 24).

3. Replace the blade (

Page 41).

4. Adjust upper blade guide so it is as close as possible

to workpiece (

Page 26).

5. Use wider blade.

6. Adjust the blade tracking back to normal.

7. Tighten table trunnion mounting bolts or tilt lock

lever.

8. Align table miter slot and fence with blade

(

Page 30).

9. Adjust blade guide bearings for correct blade sup-

port.

Summary of Contents for W1825

Page 73: ...Model W1825 For Machines Mfd Since 07 15...

Page 76: ......