32

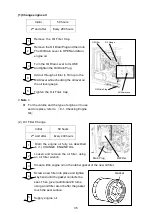

9-5. Connecting to External Fuel Tank

CAUTION

Always stop the engine, when working on the fuel line.

Always wipe any drip of Diesel fuel or oil. Do not use this equipment

when a leak is found. Repair the equipment before use.

Ensure that there is no fuel leakage on the fuel line after the fuel line

working finished.

Turn the 3-way valve lever to A position.

(Installed tank use position)

Disconnect the P/T 1/2 plugs from the

External Fuel Intake and the External Fuel

Return, and then connect the hoses from

the External Fuel Tank, as shown below.

Turn the 3-way Valve Lever to B

position.

(External tank use position)

Extract the air out from the

connected hoses.

By the above procedure, it makes

possible to use an External Fuel

Tank.

< Note >

Use always oil-proof hose in 8-10mm

inner diameter as connecting hose.

The fuel level in the external fuel tank

should be 0 to 3m higher than the bottom

of the equipment. Otherwise, it may

cause engine malfunction or stoppage.

To avoid any leak from the external fuel

intake and return ports, always turn the lever for 3-way Valve to A position

whenever piping work is performed.

Use extreme caution when connecting the hoses. If the lever position is set improper,

the fuel may leak from either the Built-in Fuel Tank or the External Fuel Tank.

Set the fuel intake position 15-20mm above from the External Fuel Intake bottom line,

otherwise water or garbage in the tank may come into the fuel line.

In order to avoid engine malfunction due to air suction, set the fuel return at the same

level as the fuel intake level in the External Tank.

Refer air extraction to

『

9-2. Procedures during Operation

』

1

2

3

4

External Fuel Tank

A side Lever Position

B side Lever Position

3-way valve

External Fuel Inlet (PT1/2)

External Fuel Return (PT1/2)

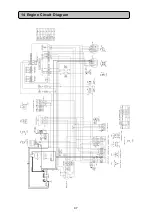

Summary of Contents for DGA50CM

Page 2: ......

Page 50: ...46 13 Generator Circuit Diagram ...

Page 51: ...47 14 Engine Circuit Diagram ...

Page 52: ... 2021 ...