Installing and wiring the drive unit

Installing the ferrite core (MU-S705)

27

Installing the ferrite core (MU-S705)

If a ferrite core is included with MU-S705, install it by following the procedure described below.

Depending on the specifications, a ferrite core may not be included with MU-S705, so installation is not required.

1

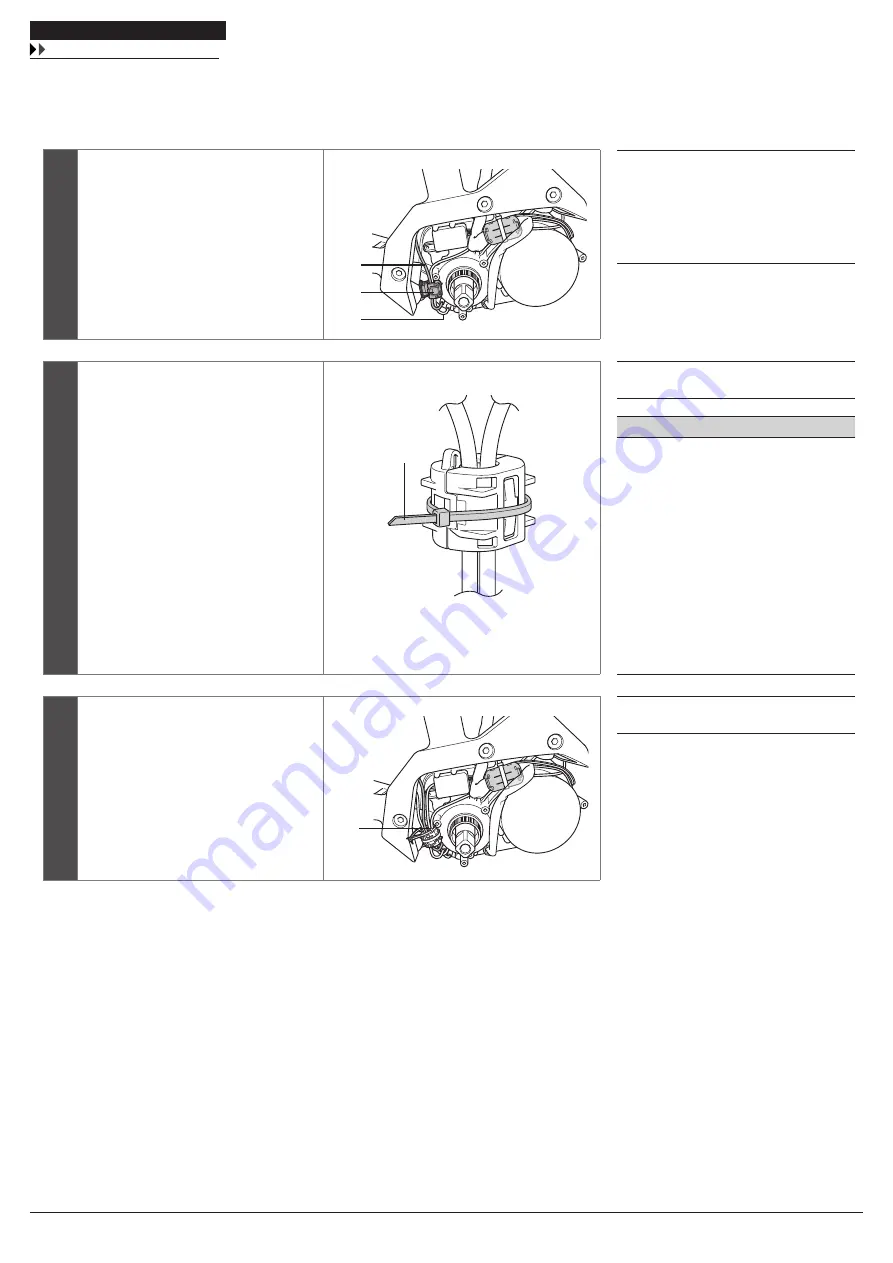

Install the ferrite core

(A)

onto electric

wire for motor unit

(B)

and electric wire

for cycle computer

(C)

.

(A)

(C)

(B)

(A)

Ferrite core

(B)

Electric wire (EW-SD50) for motor

unit

(C)

Electric wire (EW-SD50) for cycle

computer

2

Make sure that the electric wires are not

pinched and firmly secure the ferrite

core.

Then, fix the ferrite core with the zip tie

(D)

.

The zip ties are included with MU-S705.

(D)

(D)

Zip tie

NOTE

•

Check that the ferrite core tabs are

firmly secured.

•

Do not cut off the excess portion

of the zip tie. The cut surface of

the zip tie may scratch the cable or

case.

•

Do not drop the ferrite core or

subject it to any shocks. Subjecting

the ferrite core to shocks will

cause it to break or crack,

rendering it unusable.

3

Pass the zip tie through projection

(E)

located at the top of the ferrite core.

Bundle together the electric wires and

peripheral wires, and fix them with the

zip tie.

(E)

(E)

Projection

Summary of Contents for BT-E6000

Page 8: ...Installation ...

Page 20: ...Installing and wiring the drive unit ...

Page 30: ...Charging the battery ...

Page 35: ...Cycle Computer Display and Setting ...

Page 50: ...Connection and communication with the PC ...

Page 55: ...MAINTENANCE ...