TROUBLE

CAUSES

TROUBLESHOOTING

Air does not

come out from

the tool.

The tank in

not under

pressure.

Switch on the machine and

wait until the tank is loaded

verifying the pressure on

the proper pressure gauge.

Wrong

adjustment

of the output

pressure.

Check that the value

indicated on the pressure

gauge at output is greater

than 0 (zero) bar.

The tool is

damaged.

Check the integrity and

efficiency of the tool.

Pressure

decrease in the

air tank.

Leaks from

the air tube,

the tool or the

pneumatic

plant.

1.

Check the integrity of the

pneumatic plant.

2.

Check the integrity of the

air tube and of the tool.

3.

Verify that the machine

air tube and air tube tool

connections are right.

4. Make sure that the

condensate drain valve is

well closed.

Tripping of the

safety valve.

Pressure

switch faulty.

Apply to an

authorized dealer.

Air leak from

the valve of the

pressure switch

with stopped

machine.

Check valve

dirty or worn.

The machine

vibrates and/

or emits a lot of

noise.

Mechanical

break.

Frequent starts

and low yield.

Air filters

dirty.

Clean the filters.

PACKAGING

SPARE PARTS

Original spare parts for possible replacements are to

be requested exclusively to the manufacyurer or to the

authorized dealer.

It is strictly forbidden to replace any components of

the machine with non original spare parts.

PACKAGING

The machine is packed by the Manufacturer in a cardboard box

equipped with two handles and containing No. 1 Dry compressor

and No. 1 Use and maintenance instructions.

UNPACKING

Once the package has been positioned on the floor, on an even

surface assuring its stability, unpack the machine removing it from

the package observing the instructions contained.

STORAGE

If the machine is not used for a long time, it is neces-

sary to store it in a safe place, provided with proper

temperature and humidity, as well as to protect it

against dust.

Before storing the machine, it is recommended to drain

the condensate from the air tank.

It is recommended to dispose the package according

to the different types of materials in full observance of

the laws in force in the country of use.

Ain order to allow the authorized operators to work

in safe places, it is suggested to assure a minimum

distance (1 m) from others, objects and/or obstructions.

POSITIONING

The machine must be used in a work place having

the features described, positioned on an even floor

assuring its stability relation to its overall dimensions

and weight.

bar

0

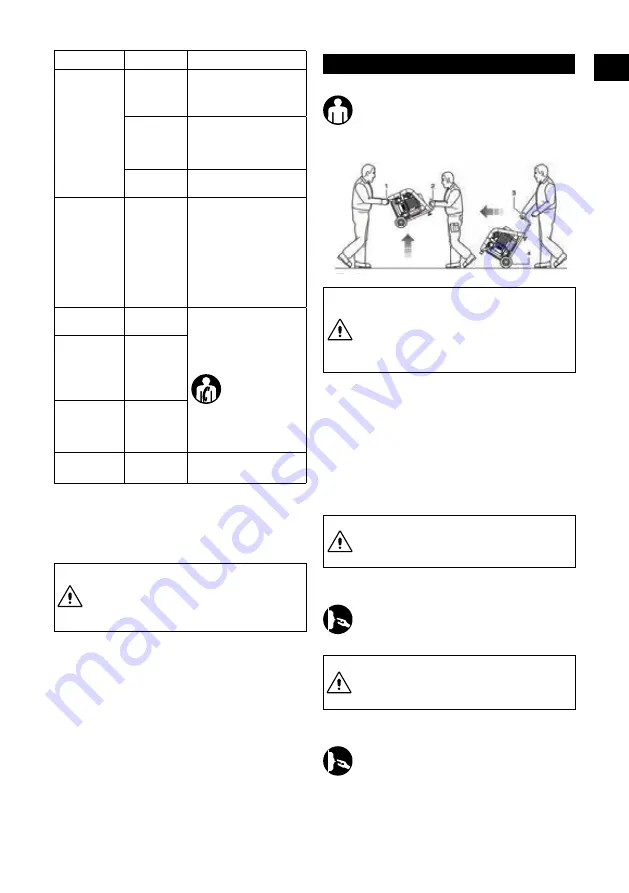

The transport of the manchine must compulsorily be

carried out by two charged operators in compliance

with the regulations on the “manual handling of

loads”, in order to avoid unfavourable ergonomic con-

ditions that may involve risks of spine/lumbar lesions.

MACHINE TRANSPORT AND HANDLINGT

The machine can be transported manually by two charged

operators by seizing it by the bearing foot and the handle

or handled manually by a charged operator using the

handle and the wheels with which it is equipped.

bar

0

9

EN

Summary of Contents for ISANTA AC19306BL

Page 94: ...18 2006 42 EC 1 10 5 2 7 10 7 10 3 4 94 RU...

Page 95: ...bar 0 5 6 95 RU...

Page 96: ...1 2 ON OFF ON I 10 3 1 2 3 4 0 5 6 7 5 1 2 3 ON OFF 4 5 6 7 23 2 3 4 5 1 7 8 9 4 5 96 RU...

Page 98: ...bar 0 2 5 2 bar 0 1 7 bar 0 0 bar 0 1 ON OFF ON I 2 3 4 ON I 1 2 bar 0 98 RU...

Page 110: ...I 18 2006 42 EC 1 10 5 bar 2 7 bar 10 bar 7 bar 10 bar 3 110 GR...

Page 111: ...PPE bar 0 4 5 6 0 10 bar 111 GR...

Page 112: ...5 1 2 3 ON OFF 4 5 6 7 2 3 4 5 1 7 8 9 1 2 3 4 ON OFF OFF 0 5 6 7 2 5 112 GR...

Page 114: ...bar 0 ON OFF OFF 0 bar 0 1 2 ON OFF OFF 0 1 ON OFF Off 0 2 24 114 GR...

Page 115: ...w 2 5 bar 2 1 7 bar 0 bar 0 1 ON OFF ON I 2 3 4 ON I 26 1 2 0 bar bar 0 115 GR...

Page 116: ...1 2 3 4 1 1 12 1 2 bar 0 bar 0 116 GR...

Page 191: ...18 2006 42 EC 1 10 5 2 7 10 7 10 3 191 191 BG...

Page 192: ...bar 0 ppe ppe 4 5 6 0 10 192 192 BG...

Page 193: ...1 2 3 ON OFF 4 5 6 7 1 2 3 4 ON OFF OFF 0 5 6 7 2 3 4 5 1 7 8 9 9 193 193 BG...

Page 195: ...ON OFF OFF 0 1 on off On pos 0 2 1 2 bar 0 ON OFF OFF 0 bar 0 10 2 195 195 BG...

Page 196: ...bar 0 2 5 2 N B 1 7 bar 0 1 ON OFF I 2 3 4 ON I 1 2 0 bar 0 196 196 BG...