1.

Connect the machine to the mains by inserting the

power supply plug in the proper outlet;

2.

Switch on the machine by pulling the “ON-OFF”

switch in pos. “ON (I)” (the machine works until the

max. operation pressure of 10 bar is reached, then

it stops automatically);

3. Adjust pressure at output using the proper

regulator, according to the used tool and to the

type of processing. Check pressure in the proper

pressure gauge ;

4. Connect the tool to the air tube (extension);

5.

Connect the air tube (extension) to the fast air

outlet tap of the machine;

It is strictly forbidden to use air tubes (extensions),

fittings, and tools not suitable and/or not

complying with the regulations in force.

It is compulsory to use air tubes (extensions),

fittings, and tools, complying with the provisions

It is strictly forbidden to commission the machine in

environments with potentially explosive atmosphere

and/or in presence of combustible dusts (ex: wood

dusts, flours, sugars and middlings).

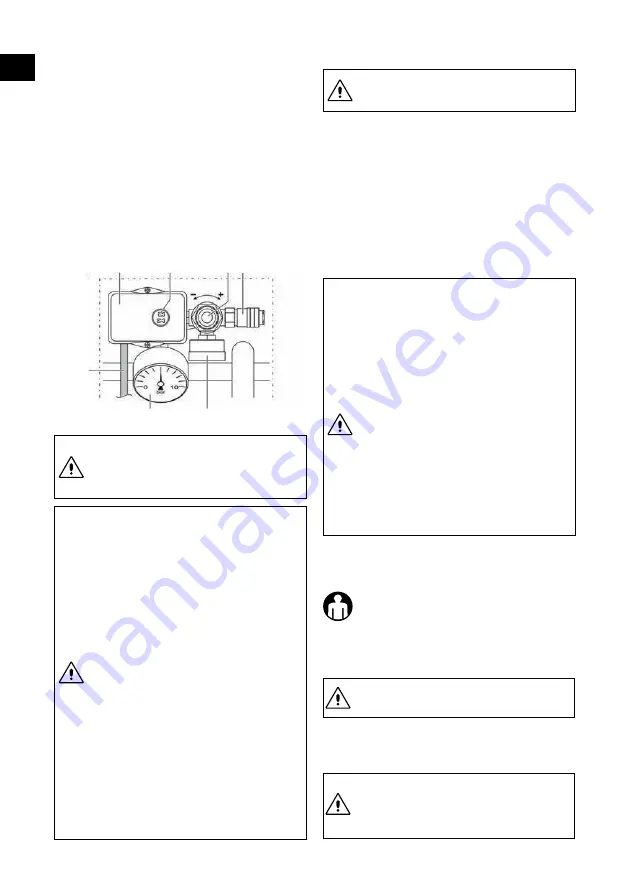

COMMAND DEVICES

They are shown

1.

Power supply cable

2.

Pressure switch

3.

“ON-OFF” switch

4.

Pressure regulator at output

5.

Fast air outlet tape

6.

Pressure gauge at output

7.

Tank pressure gauge

CHECKS BEFORE SWITCHING ON

Before switching-on of the machine, the

authorized operators must compulsory

perform the following checks.

1.

Make sure that there are not any non-authorized persons

close to the machine.

2.

Make sure that the safety devices are integral and properly

installed and working .

3.

Make sure that the machine is properly positioned .

4.

Make sure that the “ON-OFF” switch or selector is positioned

on “OFF (0)”.

5.

Make sure that the condensate drain valve is closed .

6.

Use the compulsory personal protection devices (PPE) .

7.

Make sure that you have read and understood the “Use and

Maintenance Instructions ” in all its parts.

MACHINE SWITCHING ON

The authorized operators can switch on

the machine only after having compulsorly

performed the checks described.

Before using this machine, the authorized operators

must read and understand this manual in all its part.

During the use, it is compulsory to verify that non-

authorized people do not get close to the machine.

The authorized operators are not allowed

to let the machine unattended during

operation and maintenace interventions.

Hazard of burning by accidental contact with the

bi-cylindrical pumping assembly and the electric

motor. Caution! There is a residual risk.

The manufacturer declines all liability for

damages to persons, animals and things,

due to the inobservance of the standards

and warnings described in this manual.

The manufacturer declines all liability on the final

result of the processing given that it depends

expends exclusively on the type of tool used and on

the professional skils of the authorized operators.

2

3

4

5

1

7

8

USE LIMITS

This machine was designed and produced exclusively for the

intended use described in par.9 , any other use and operation

is therefore absolutely forbidden in order to assure in every

moment the safety of the charged operators, as well as the

efficiency of machine itself.

It is forbidden to screw the pressure regulator at

output. Beyond the end of stroke, in order to avoid

damaging the membrane.

Limitations in use: it is strictly forbidden to use

the machine for improper used, differing from the

foreseen use (par.9).

It is compulsory to keep the machine out of the reach

of children.

During the use, it is compulsory to verify that non-

authorized people do not get close to the machine.

It is strictly forbidden to use air tubes (extensions),

fittings, and tools not suitable and/or not complying

with the regulations in force.

It is strictly forbidden to life the machine with cranes

and/or fork lift trucks.

It is strictly forbidden to direct compressed air jets

against persons, animals and things.

It is strictly forbidden to use the machine to transport

and/or lift persons, animals and things.

It is strictly forbidden to get on the machine.

It is strictly forbidden to tow the machine by any

means and/or vehicle whatsoever.

It is strictly forbidden to move the machine manually

on upwards and/or downwards slopes with

hazardous grade.

Hazard of burning by accidental contact with the

bi-cylindrical pumping assembly and the electric motor.

Caution! There is a residual risk.

6

EN

Summary of Contents for ISANTA AC19306BL

Page 94: ...18 2006 42 EC 1 10 5 2 7 10 7 10 3 4 94 RU...

Page 95: ...bar 0 5 6 95 RU...

Page 96: ...1 2 ON OFF ON I 10 3 1 2 3 4 0 5 6 7 5 1 2 3 ON OFF 4 5 6 7 23 2 3 4 5 1 7 8 9 4 5 96 RU...

Page 98: ...bar 0 2 5 2 bar 0 1 7 bar 0 0 bar 0 1 ON OFF ON I 2 3 4 ON I 1 2 bar 0 98 RU...

Page 110: ...I 18 2006 42 EC 1 10 5 bar 2 7 bar 10 bar 7 bar 10 bar 3 110 GR...

Page 111: ...PPE bar 0 4 5 6 0 10 bar 111 GR...

Page 112: ...5 1 2 3 ON OFF 4 5 6 7 2 3 4 5 1 7 8 9 1 2 3 4 ON OFF OFF 0 5 6 7 2 5 112 GR...

Page 114: ...bar 0 ON OFF OFF 0 bar 0 1 2 ON OFF OFF 0 1 ON OFF Off 0 2 24 114 GR...

Page 115: ...w 2 5 bar 2 1 7 bar 0 bar 0 1 ON OFF ON I 2 3 4 ON I 26 1 2 0 bar bar 0 115 GR...

Page 116: ...1 2 3 4 1 1 12 1 2 bar 0 bar 0 116 GR...

Page 191: ...18 2006 42 EC 1 10 5 2 7 10 7 10 3 191 191 BG...

Page 192: ...bar 0 ppe ppe 4 5 6 0 10 192 192 BG...

Page 193: ...1 2 3 ON OFF 4 5 6 7 1 2 3 4 ON OFF OFF 0 5 6 7 2 3 4 5 1 7 8 9 9 193 193 BG...

Page 195: ...ON OFF OFF 0 1 on off On pos 0 2 1 2 bar 0 ON OFF OFF 0 bar 0 10 2 195 195 BG...

Page 196: ...bar 0 2 5 2 N B 1 7 bar 0 1 ON OFF I 2 3 4 ON I 1 2 0 bar 0 196 196 BG...