14

CRAFT-STICK | Version 1.12

Troubleshooting

9

Troubleshooting

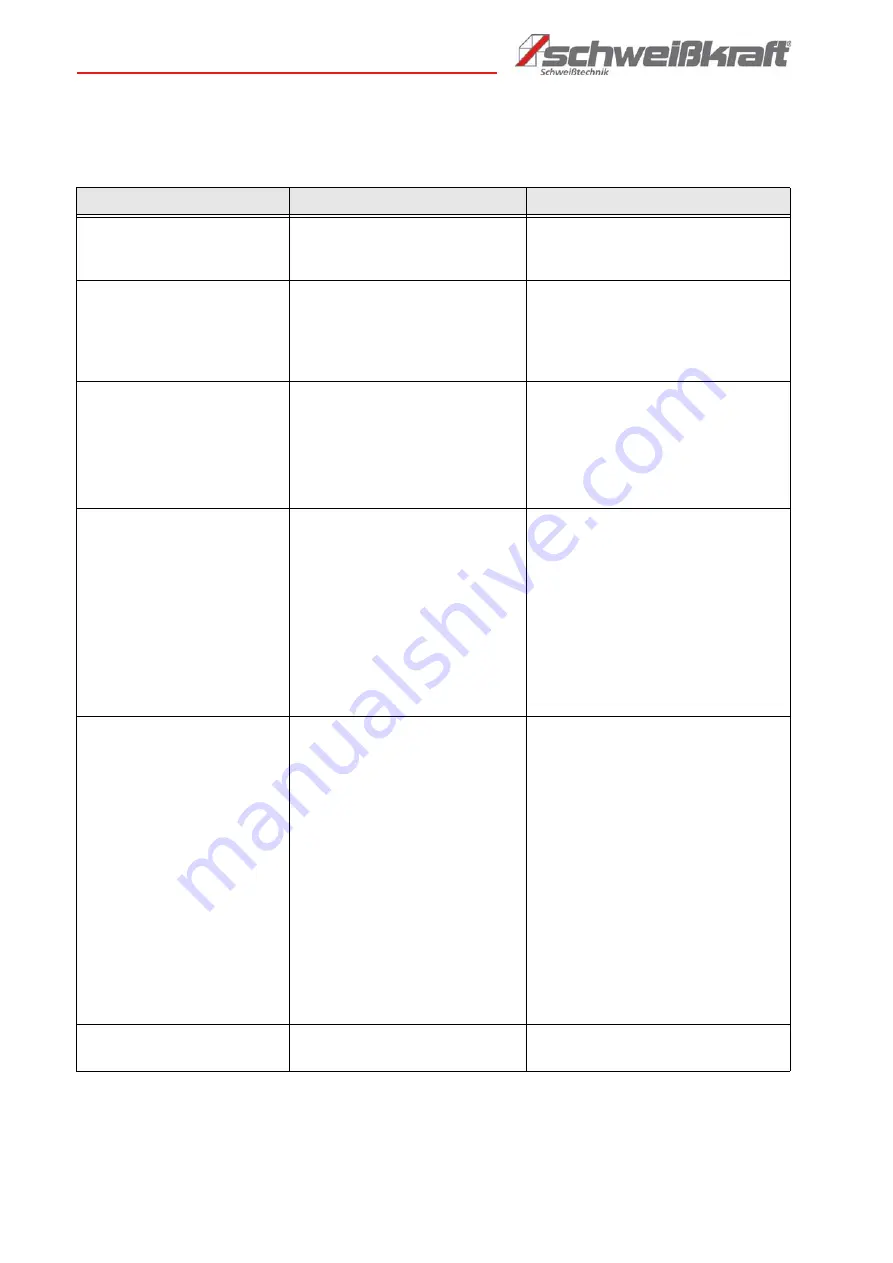

9.1 Electrode welding

Fault

Possible cause

Solution

Air bubbles in the weld seam

(porosity).

1. Wet electrodes.

2. Welding current too high.

3. Surfaces dirty with oil, paint etc.

1. Dry the electrodes before use.

2. Reduce the welding current.

3. Clean the edges before welding.

Visible cracks in the weld seam

immediately after solidification.

1. Edges too rigid.

2. Weld throat too small.

3.Cooling too fast.

1. Avoid stresses due to edge shape.

2. Reduce the working speed to obtain a

more uniform deposit.

3. Preheat the workpiece and cool it

slowly.

Cracks due to poor filling of the

throat.

1. Welding current too low.

2. Electrode too large for connection.

3. Throat unsuitable.

4. Wrong welding sequence.

1. Increase the welding current.

2. Use electrodes with a smaller diame-

ter.

3. Enlarge the throat.

4. Follow the correct welding sequence.

Parts of the workpiece not mol-

ten to the sheet metal or joint.

1. Electrodes too thin for the work-

piece to be welded.

2. Welding current too low.

3. Electrode used at the wrong

angle.

4. Too fast movement of the

electrode.

5. Slag or dirt on the surface of the

workpiece.

1. Use electrodes with a larger diameter

and preheat the workpiece.

2. Increase the welding current.

3. Correct the welding angle towards the

base plate.

4. Reduce the speed of the electrode.

5. Clean the surfaces before welding.

Non-metallic material in the weld

pool (slag inclusions).

1. Particles in the lower layers of the

preceding passages.

2. Prepared joint too narrow.

3. An irregular surface promotes slag

containment.

4. Poor penetration of slags trapped

under the weld pool.

5. Rust or splinters prevent complete

melting.

6. Wrong electrode for the intended

welding position.

1. In case of bad welding, remove the

slag and replace the base with a small

diameter electrode.

2. Provide adequate space for cleaning

the slag.

3 If necessary, grind off the entire bad or

irregular area.

4. Remove all slags from the corners.

Use smaller electrodes to allow proper

penetration.

5. Clean the edge before welding.

6. Use electrodes appropriate to the posi-

tion to be welded, otherwise removing

the slag will be difficult.

Fuse is triggered

1. High power consumption

1.Ensure that the house installation is

sufficiently dimensioned.

Summary of Contents for 1073141

Page 25: ...CRAFT STICK Version 1 12 25 Notes 15 Notes ...

Page 26: ...www schweißkraft de ...