CRAFT-STICK | Version 1.12

15

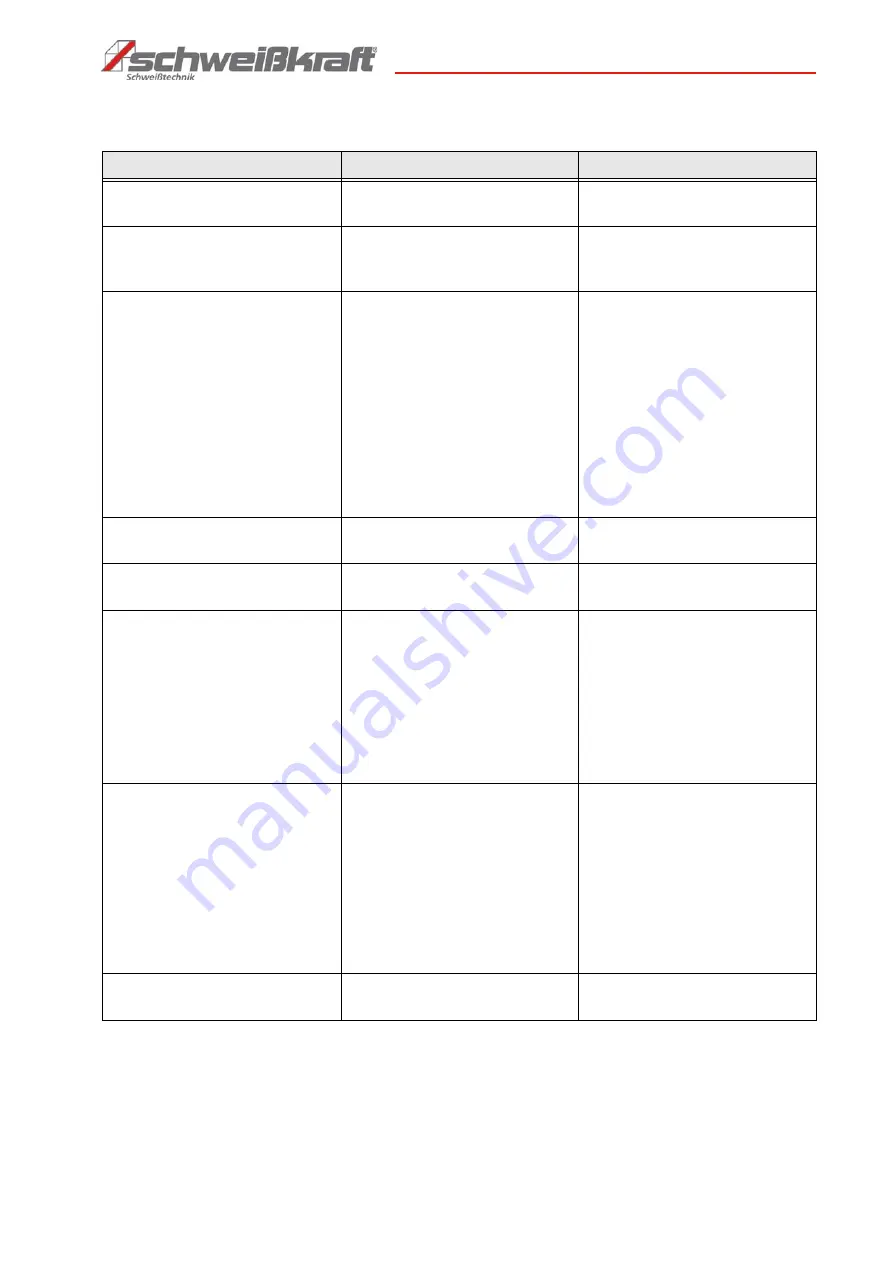

Troubleshooting

9.2 TIG welding

Fault

Possible cause

Solution

The electrode melts when the arc is

skipped.

1. Electrode connected to output "+".

1. Connect electrode to output "-".

The weld bath is dirty.

1. Electrode contaminated by contact

with the weld bath or rod.

2. Gas contaminated with air.

1. New sharpen the electrode.

2. Check the gas pipes or replace the

cylinder.

The electrode melts or oxidizes when

the arc is skipped.

1. The gas does not reach the weld

bath.

2. Burner blocked by contamination.

3. Gas hose is cutting in.

4. Gas path contains impurities.

5. Gas valve closed.

6. Burner valve closed.

7. Electrode too small for the current

used.

1. Check for obstructions in the gas

pipes and check the cylinder.

2. Clean the burner.

3. Replace the gas hose.

4 Disconnect the gas supply from the

burner and increase the pressure

to blow the impurities out.

5 Open the gas valve.

6. Open the burner valve.

7. Reduce the welding current or re-

place the electrode with a larger

one.

Visibly bad welding.

1. Insufficient shielding gas. .

1. Raise the gas flow or check the

gas supply pipe.

Arc during TIG welding is unstable.

1. Tungsten electrode too large for

the welding current.

1. Select the correct electrode size.

The welding arc does not stabilize.

1. Grounding clamp not attached to

the workpiece or clamp not

connected to the correct poles.

2. Burner cable not connected.

3. Wrong gas flow, bottle empty or

valve closed.

1. Connect the earth clamp to the

workpiece to be welded or

connect the cables of the burner

and the earth to the correct

connections.

2. Connect the burner cable to con-

tact "-".

3. Correct the gas flow rate, change

the bottle or open the valve.

Arc does not jump smoothly over.

1. Tungsten electrode too large for

the welding current.

2. Tungsten electrode not adequate

for the work to be performed.

3. Gas flow too high.

4. Use of the wrong gas.

5. Bad contact between earth clamp

and workpiece.

1 Select the correct electrode size.

2. Select the correct electrode type.

3. Select the correct gas flow rate for

the work to be performed.

4. Select the correct gas type.

5. Make sure that there is good con-

tact between the grounding clamp

and the workpiece.

Fuse is triggered

1. High power consumption

1. Ensure that the house installation

is sufficiently dimensioned.

Summary of Contents for 1073141

Page 25: ...CRAFT STICK Version 1 12 25 Notes 15 Notes ...

Page 26: ...www schweißkraft de ...