Error/Symptom

Reason

Solution

Over temperature, heating by low ambient temperatures

M.EZ-04.01-S-en-F1-extra-info EL

28-july-2011

Schischek GmbH

Germany, Mühlsteig 45, Gewerbegebiet Süd 5, 90579 Langenzenn, Tel. +49 (0)9101 9081-0, Fax +49 (0)9101 9081-77, E-Mail [email protected]

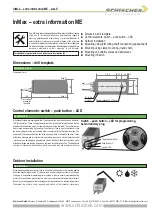

ExMax-.., RedMax-.., InMax extra information EL F1

Actuator does not work

LED ligths red

l

The actuator is operated by a too high ambient

temperature and the internal temperature sensor

responded

l

Shut off actuator and let temperature decrease, reduce ambient

temperature by suitable measures e.g. ventilation or other mounting

position of the actuator

02

Actuator does not work

LED lights green

l

3-Pos control signal is wired on both entrances

l

Required torque is greater than actuators torque

l

Control signals are not attached or attached on a

wrong conductor

l

Actuator is incorrect mounted and is blocked by an

external stop unit

l

Actuator is clocked with more than 20 impulses <0,5

per sec. and therefore adjusted into suspend mode

l

Interchanged supply lines

l

Readjust/correct circuit

l

Adjust a higher torque at the actuator if possible otherwise exchange

for a type with higher torque.

l

Examine rule and adjusting signal in accordance with attached diagram

l

Dismount actuator and testdrive without load for operability. Install

actuator accordingly that the power transmissions runs without external

blockade or torsion

l

Switch off supply voltage for at least 2 sec. thereby a reset is conducted

Readjust controller in order to extend control pulses

l

Wire 1 must be (-, N) and wire 2 (+, L)

03

05

06

07

Y-drive in the 3-pos mode can not gear

into intermediate positions

l

The conversion of constant mode on 3-pos-modus

was not set

l

Recalibrate the actuator in accordance with assembly instructions

08

Actuator sits diagonally on the squared

damper shaft

l

The actuators have an angle of rotation of 95°

inclusive 5° pre-tention. While assembling the pre-

loading was not considered

l

Dismount actuator of the damper, use the enclosed socket wrench to

draw up approx. 5° over the hand operated control device before

remounting on the damper shaft. Consider additional information

ME (size S) of the assembly instructions

A modulating actuator (Y) works with

reduced angle of rotation and already

reaches its end positions before 0 V/4

mA, respectively before 10V/20mA.

l

At start up no self adjustment of angle of rotation

was accomplished

l

Accomplish self adjustment of angle of rotation in accordance with

assembly instruction

LED flashes irregularly and actuator

does not work

l

Actuator does not receive sufficient supply voltage

l

Cable to long, voltage drop in the supply line to large

l

Increase line cross section or increase tension at the transformer/power

suply unit

l

Increase line cross section or increase tension

l

No power supply attached

l

The actuator is operated beyond ex-prevention

ambient temperature specifications and the internal

temperature sensor did irreversibly shut down

operations

l

Attache power supply and turn on

l

Because of inadmissable operation the actuator drove out of safety

relevant reasons into an irreversible condition and must be exchanged.

Accompanying new installation the ambient temperature has to be

reduced accordingly

Actuator does not work

LED does not lights

01

Acuator does not work

LED is red blinking

04

l

The actuator has been mounted by temperatures

of less than -20°C and did not reach is operating

temperatur of at least -20°C.

l

Ensure that a constant voltage supply on conductor 1--2 is existing.

l

Wait until the required operating temperature is achieved by the actuators

internal heating system.The actuator will start operating independently

E X P L O S I O N P R O O F

Error indication

I. 3 sec. motor running time

1. The 3 sec. motor running time mode is only in switch position 0 and 5 and at a constant

supply voltage on terminals 1 and 2 which must be in minimum for 1 minute applied

/available.

2. The actuator opens at voltage on terminal 3 (resp. closes), and closes at voltage on

terminal 4 (resp. opens ) depending on mounting position of the actuator.

3. The max. duty ratio is 10 % resp. 1 cycle / minute. Between two fully cycles to the same

direction there must be a minimum intermission of 1 minute. The actuator is blocked if

the break time is less than 1 minute. The release for the next cycle is made automatically

by an internal timing relay.

4. Same function is applied on spring return actuators . Faile safe operation is regarded

same as a motor running cycle.

5. If its tried to use the 1 wire On/Off methode in switch position 0 and 5, software changes

the running time temporarily and automatically to 15 sec. motor running time to protect

the actuator for overheating due to uncontrolled duty ratio.

II. Temperature rise

While operating the ..Max actuator following parameters have to be aligned:

At overload resp. temperature rise the actuator will remain functionless until cooling.

During cooing the LED is red.

III. Use at low ambient temparature below -20°C

All ..Max actuators are equipped with a regulated integrated heating device designed

for employments down to -40°C ambient temperature.

The heater will be supplied automatically by connecting the constant voltage supply on

the clamps 1 and 2.

Following parameters are to be considered by ambient temperaure < 10°C:

1. After mounting the actuator must bei immediately electrically connected.

2. The actuator will only be activated after the operating temperature has reached at least

-20°C .

3. The adjustment options are only ensured after this heating up period.

IV.Mechanical protection

1. The actuator must be operated with an outside load of at least 5 Nm.

2. After installing the actuator to the damper/armature an automatic alignment has to be

accomplished, in order to obtain a gentle blockade/stop. This function protects the

damper/armature by reducing the end positions/blockade speed in order to avoid

mechanical overload. The actuator alignes specifically once with 90 sec./90° onto each

position, recognizes the blockade position in order to reduce the motor performance

during operation briefly before reaching the end/blockade position.

www.schischek.com