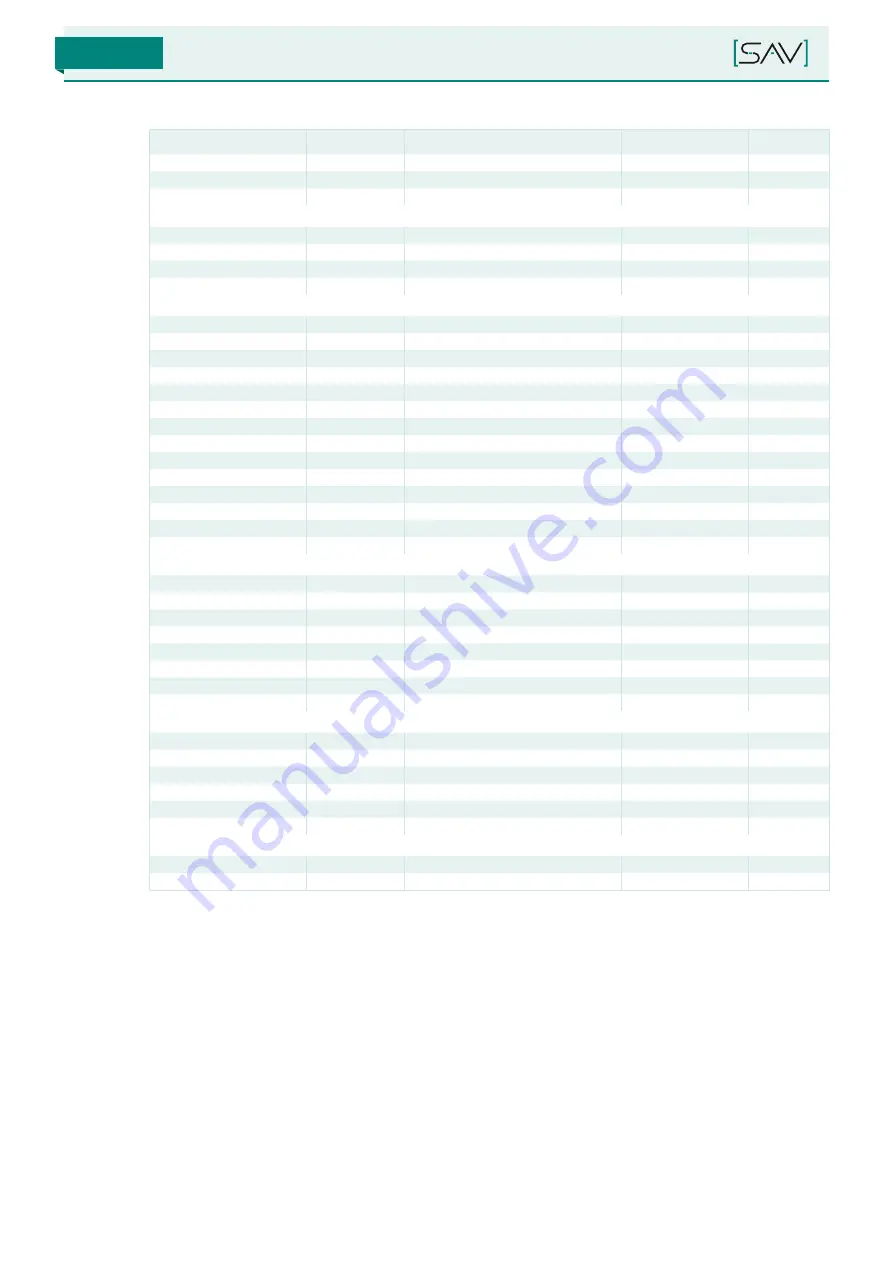

3 TECHNICAL SPECIFICATIONS

Short designation as per DIN

Material no.

Max. non-magnetic alloy component

Heat treatment

Holding force

31CrMoV9

1.8519

4.65 %

nitrided

49 %

34CrAlNi7

1.8550

5.93 %

nitrided

46 %

39CrMoV13-9

1.8523

6.44 %

nitrided

44 %

Free machining steel

15S10

1.0710

1.77 %

untreated

90 %

9SMn28

1.0715

1.92 %

untreated

89 %

45S20

1.0727

2.21 %

untreated

88 %

60SPb20

1.0758

2.71 %

untreated

85 %

Q & T steel

C22

1.0402

2.96 %

soft

84 %

C45

1.0503

3.20 %

soft

83 %

Ck45

1.1191

3.50 %

soft

81 %

C60

1.0601

3.57 %

soft

81 %

Ck60

1.1221

3.65 %

soft

80 %

43CrMo4

1.3563

3.62 %

soft

80 %

36CrNiMo4

1.6511

4.37 %

soft

77 %

C22

1.0402

2.96 %

annealed

49 %

C45

1.0503

3.20 %

annealed

48 %

Ck45

1.1191

3.50 %

annealed

47 %

C60

1.0601

3.57 %

annealed

47 %

Ck60

1.1221

3.65 %

annealed

47 %

43CrMo4

1.3563

3.62 %

annealed

47 %

36CrNiMo4

1.6511

4.37 %

annealed

45 %

Ball bearing steel

100Cr6

1.3501

3.11 %

soft

83 %

100CrMn6

1.3520

5.26 %

soft

73 %

X102CrMo17

1.3543

22.72 %

soft

26 %

X82WMoCrV6-5-4

1.3553

11.40 %

soft

44 %

100Cr6

1.3501

3.11 %

hardened

43 %

100CrMn6

1.3520

5.26 %

hardened

38 %

X102CrMo17

1.3543

22.72 %

hardened

13 %

X82WMoCrV6-5-4

1.3553

11.40 %

hardened

24 %

Spring steel

Ck67

1.1231

2.04 %

soft

88 %

60SiMn5

1.5142

3.15 %

soft

83 %

51MnV7

1.5225

2.87 %

soft

84 %

Ck67

1.1231

2.04 %

hardened

46 %

60SiMn5

1.5142

3.15 %

hardened

43 %

51MnV7

1.5225

2.87 %

hardened

44 %

Cold extrusion steel

Cp15

1.1132

1.10 %

soft

94 %

41Cr4

1.7035

3.55 %

soft

81 %

SAV 531.42

Version 1.0

[

78

]

Summary of Contents for SAV 531.42

Page 3: ...BATTERIE LASTHEBEMAGNETE BETRIEBSANLEITUNG Version 1 0 DE SAV 531 42 just experts ...

Page 56: ...SAV 531 42 NOTIZEN Version 1 0 56 ...

Page 57: ...BATTERY POWERED LIFTING MAGNETS OPERATING INSTRUCTIONS Version 1 0 EN SAV 531 42 just experts ...

Page 110: ...NOTES SAV 531 42 Version 1 0 110 ...

Page 111: ......