23

Ins

tallation Pr

oc

edur

e

English

3

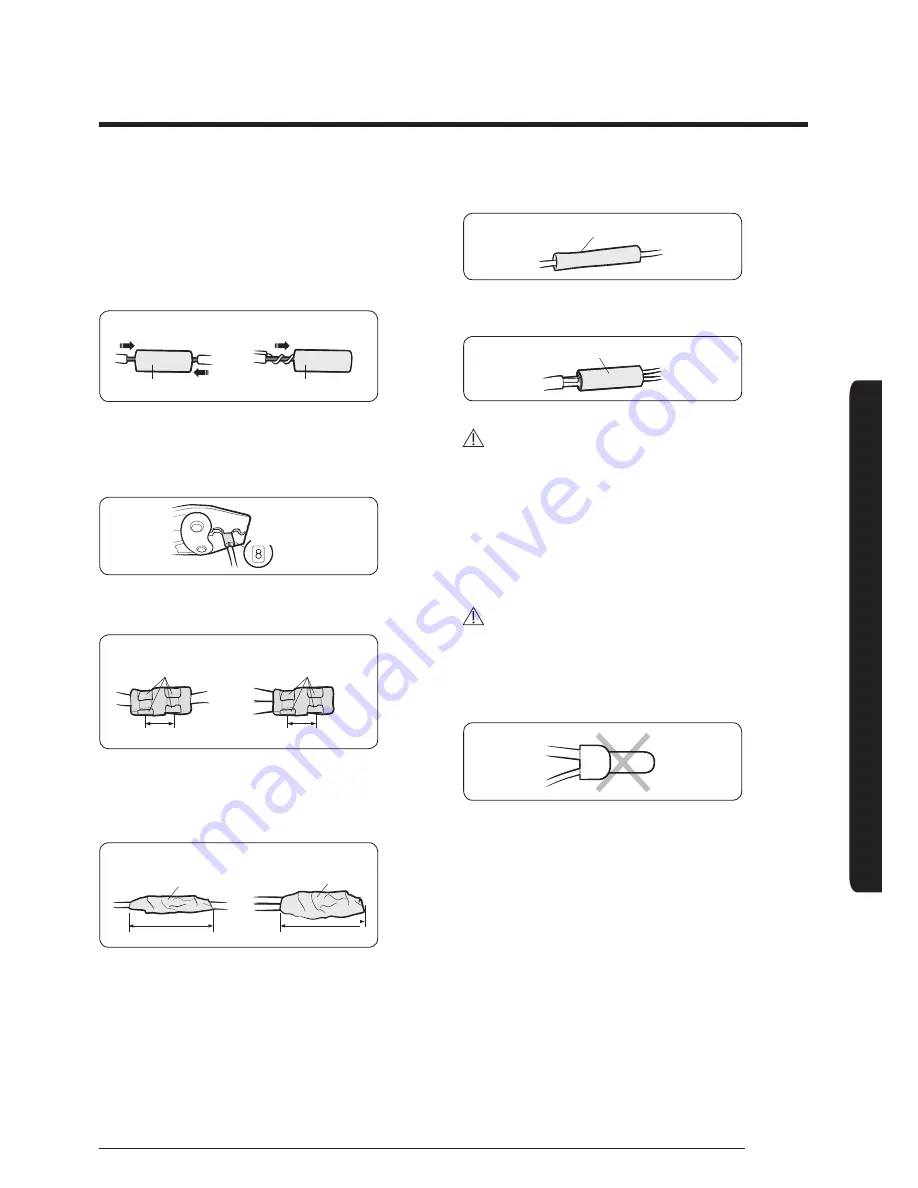

Insert both sides of core wire of the power cable into the

connection sleeve.

•

Method 1

: Push the core wire into the sleeve from

both sides.

•

Method 2

: Twist the wire cores together and push it

into the sleeve.

Method 1

Method 2

Connection sleeve

Connection sleeve

4

Using a crimping tool, compress the two points and flip

it over and compress another two points in the same

location.

•

The compression dimension should be 8.0.

Compression

dimension

•

After compressing it, pull both sides of the wire to

make sure it is firmly pressed.

Method 1

Method 2

Compress it 4 times

Compress it 4 times

5 mm

5 mm

5

Wrap it with the insulation tape twice or more and

position your contraction tube in the middle of the

insulation tape.

Three or more layers of insulation are required.

Method 1

Method 2

Insulation tape

Insulation tape

40 mm

35 mm

6

Apply heat to the contraction tube to contract it.

Contraction tube

7

After tube contraction work is completed, wrap it with

the insulation tape to finish.

Insulation tape

CAUTION

•

Make sure that the connection parts are not exposed

to outside.

•

Be sure to use insulation tape and a contraction tube

made of approved reinforced insulating materials that

have the same level of withstand voltage with the

power cable. (Comply with the local regulations on

extensions.)

WARNING

•

In case of extending the electric wire, please DO NOT

use a round-shaped pressing socket.

– Incomplete wire connections can cause electric shock

or a fire.

Summary of Contents for AE071MNMPEH

Page 40: ......