Operator’s manual

Double-sided disc mowers

with central suspension

- 9 -

3.2.3.

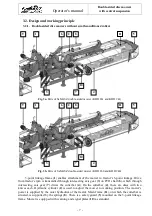

Double-sided disc mowers with roller conditioner.

Fig. 3e. Parts of SaMASZ double-sided mower with roller conditioner (KDD 860 W and KDD 940 W)

3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive

from tractor’s rpm is transmitted through intersecting axis gear (3) on PTO shaft (6), which through

intersecting axis gear (7) drives the cutterbar (4). On the cutterbar, there are discs with two knives

each. Apart from that, drive from tractor’s rpm through intersecting axis gear (3), PTO shaft (6),

intersecting axis gear (7) and chain gearbox (13) is transmitted to roller conditioner (14). Hydraulic

cylinder (2) is used to adjust the mower to working position. It is supplied from outer hydraulics of

the tractor. Main frame, on which the cutterbar (4) is situated, is supported by the springs (8). On

top of roller conditioner’s safety guard, there are swath guides (5) mounted.

3.2.4.

Belt conveyors

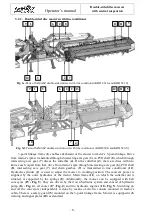

Fig. 4. Hydraulic system of belt conveyors

Fig. 5. Belt conveyor

Additionally, the mower can be equipped with belt conveyors (15 - Fig. 5). They are driven

by their own hydraulic system and consist of hydraulic pump (16 - Fig. 4), oil cooler (17 - Fig. 4)

and two hydraulic engines (18 - Fig. 5). Switching on and off the conveyors (independent) is done

by means of electric console mounted in tractor’s cabin. There is safety guard (5) mounted on the 3-

point linkage frame. Mower is equipped with warning and signal plates (10) as standard.

7

11

13

3

5

8

14

2

6

1

9

10

16

17

15

18