Operator’s manual

Double-sided disc mowers

with central suspension

- 48 -

4.

Mount the new belt upwards.

5.

Mount front belt P.

6.

Mount front tensioners and tighten rear tensioner.

III.

Maintenance of belt conveyor adjusted in "work" position - inclination towards the

ground should be 23°.

1.

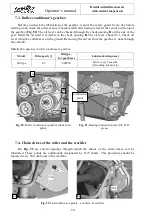

Mark two lines on newly mounted belt in intervals of l = 3.9" (Fig. 47).

2.

With adjustment screws S

2

tighten the roller so the distance on belt between marked lines is

l

= 3' 4" - 3' 4.2" (lines on measures from item I. 1 may prove to be helpful). The distance

between the lines may differ on both edges of conveyor's belt.

Fig. 47.

3.

Measure diagonals with use of 9' 10" measure using angle bars.

4.

Start the mower and in particular hydraulic drive, gradually increasing rpm from 0 to 1250 rpm.

5.

Adjust with screws S

2,

locking screws S

1

each time – to be repeated until fine tuned, so there

are no bulges on the belt.

IMPORTANT:

Precision is recommended, so belts and their edges work symmetrically on

rollers. Well-adjusted belts cannot bulge in places where v-belt is guided

inside the roller channel.

7.

LUBRICATION

7.1.

Cutterbar

Refilling oil in the cutterbar is done through the inlet A (Fig. 48). Proper oil level is 0.2" -

0.3" from the cutterbar bottom.

Tab. 6. Oil capacities

Model

Oil capacity

[l]

Oil type

Lubrication frequency

KDD 861 (S/W (H) (T)) - 8,60 m

KDD 860 (S/W (H)) - 8,60 m

2 x 6,0

80W90

Once every 3 seasons

(if working intyensively, more

frequently)

KDD 941 (S (H) (T)) - 9,40 m

KDD 940 (S/W (H)) - 9,40 m

2 x 6,5

S

2

S

2

S

1

measure

l