Operator’s manual

Double-sided disc mowers

with central suspension

- 51 -

7.5.

Lubrication points

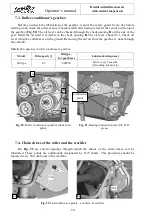

Every 50 mower working hours, lubricate tine/roller conditioner’s bearings (Fig. 53, 54) with

LT43 grease (or other designed to lubricate rolling and slide bearings, that work in -30

to +130

o

C)

and main joints of the mower with STP grease and all connections in cylinders (Fig. 55) with STP

lubricant.

Fig. 53. Bearing lubrication point withLT43 grease

Fig. 54. Bearing lubrication point with LT43 grease

Fig. 55. Lubrication point of the suspension with STP grease

Lubrication

point

Lubrication

point

Lubrication

points

Lubrication

points