ENGLISH

15

Other

impeller

diameters

:

P

suction

+

P

differential

+

0,5

bar

Flow

:

Delivered

flow

should

be

between

0,1

and

0,2

m

3

/h

Quench

:

Max

Pressure

=

4

bar

Heating

:

Max

pressure

=

4

bar

with

water

vapor

at

140°C

Gland

packing

assembly

:

A

small

leakage

of

packing

gland

is

necessary

to

ensure

proper

lubrication

of

the

packing

rings

(20

to

40

drops

per

minute

is

acceptable).

If

there

is

not

enough

leakage

then

packing

ring

will

be

destroyed

rapidly.

Check

that

the

external

liquid

supply

of

the

gland

packing

is

turned

on

before

starting

‐

up

the

pump

(if

applicable).

Mechanical

seal

assembly

:

For

pumps

equipped

with

a

quench,

external

flushing,

or

a

heating

system,

check

that

the

external

liquid

supply

is

turned

on

before

starting

‐

up

the

pump.

In

any

case

the

mechanical

seal

should

have

time

to

cool

down

between

two

starts.

8.5

SHUTDOWN

Before

the

pump

is

stopped

close

the

discharge

isolating

valve.

Ensure

that

the

pump

runs

in

that

condition

no

more

than

few

seconds.

When

the

pump

has

come

to

a

standstill

:

close

the

suction

isolating

valve.

If

the

pump

is

equipped

with

auxiliary

systems

such

as

a

quench,

heating

system,

flushing,

external

lubrication,

etc

…

it

must

be

closed

at

the

last

step.

If

temperature

is

likely

to

drop

below

freezing

point,

pump

casing

and

auxiliary

connected

systems

should

be

completely

drained

or

otherwise

protected.

For

prolonged

shut

‐

downs

an

adapted

rust

protective

coating

should

be

applied

to

the

inside

and

outside

of

the

pump.

Pumping

explosive,

toxic

or

polluting

fluids

:

make

sure

that

all

necessary

actions

were

taken

to

avoid

the

creation

of

a

hazard

for

people

or

environment

during

drainage

operations.

Products

which

are

sent

back

to

Salmson

must

be

drained

and

cleaned.

Pumped

fluid

should

be

completely

removed

from

the

pump.

9

MAINTENANCE

9.1

GENERAL

INFORMATION

Only

properly

trained

and

skilled

staff

should

undertake

maintenance

operations.

Only

authorized

personnel

should

undertake

maintenance

on

ATEX

certified

equipments.

Make

sure

to

avoid

creation

of

explosion

hazard

while

proceeding

to

maintenance

in

a

ATEX

zone.

All

technical

documents

delivered

with

the

pump

should

be

known

and

should

be

available

near

the

pump.

The

maintenance

crew

should

be

informed

about

the

risks

linked

to

the

use

of

the

pump

and

to

the

pumped

fluids

before

they

can

start

working

on

the

equipment

(dangerous

products,

fluid

and

pump

temperature,

pressurized

parts,

…).

They

should

be

equipped

with

all

appropriated

individual

safety

protections

(glasses,

gloves,

…)

and

should

respect

local

industrial

and

security

rules.

Pump

contains

a

part

of

pumped

fluid

even

when

it

is

at

a

standstill.

Drain

and

flush

pump

casing

with

care

before

starting

pump

disassembly.

Appropriate

lifting

devices

should

be

available

to

help

personnel

moving

heavy

loads.

The

maintenance

area

must

be

clearly

identified.

Install

warning

boards

with

the

words

«

WARNING

:

machine

under

repair

!

»

on

the

pump

and

on

the

control

cabinet.

Any

work

on

the

machine

must

be

performed

when

pump

is

stopped.

Prior

to

any

maintenance

or

repair

work

the

motor

should

be

electrically

isolated

and

secured

against

uncontrolled

start.

Lock

the

main

switch

open

and

disconnect

circuit

breaker.

Withdraw

the

fuses

if

any.

WARNING

:

electrical

equipments

that

must

be

powered

on

during

the

maintenance

work

or

pressurized

equipments

must

be

clearly

identified.

End

of

maintenance

operations

:

all

protective

parts

that

were

removed

before

maintenance

should

be

reinstalled

and

all

security

devices

should

be

reactivated.

Pump

surrounding

area

should

be

cleaned.

9.2

MAINTENANCE

AND

PERIODIC

INSPECTIONS

SCHEDULE

It

is

recommended

to

build

up

a

maintenance

and

inspection

plan

to

ensure

a

reliable

use

of

pump

and

to

reduce

malfunctions

hazards.

Following

check

points

should

be

included

in

this

maintenance

plan

:

Check

state

and

working

of

securities

and

auxiliary

systems,

Check

and

adjust

gland

packing

(if

any)

for

visible

leakage,

Check

for

any

leaks

from

pump

gaskets

and

flanges

seals,

Check

lubricant

level

and

aspect

of

oil

(oil

lubricated

bearings)

in

bearing

bracket,

Check

running

time

and

replacement

frequency

of

lubricants

/

ball

bearings,

Check

the

bearing

bracket

housing

surface

temperature

on

ball

bearings

area,

Check

dirt

and

dust

is

removed

from

pump

and

motor

,

Check

coupling

alignment

(depending

on

pump

variant),

Check

if

there

is

unusual

noises

(cavitations,

hissing,

purring,

…)

or

excessive

vibrations.

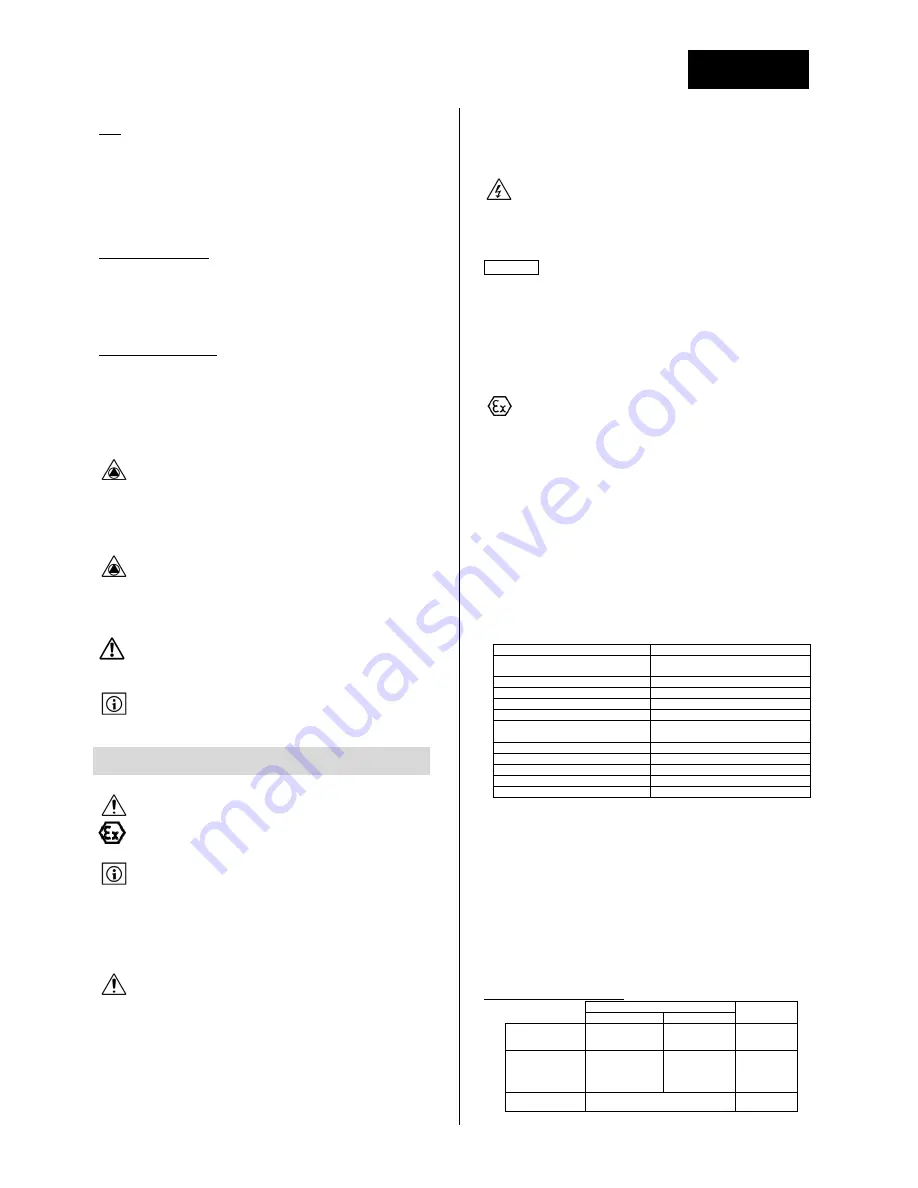

Check

point

Periodicity

State

of

the

auxiliary

systems

Depends

on

equipment

type.

See

dedicated

equipment

IOM

Motor

See

manufacturer

IOM

Shaft

sealing

Weekly

Leaks

from

gaskets

Weekly

Oil

level

and

grease

quantities

Daily

/

Weekly

/

Monthly

Lubricants

(ball

bearings)

Replacement

frequency

according

ball

bearing

type

and

shaft

speed

Bearings

surface

temperature

Monthly

Cleaning

Twice

a

year

Alignment

and

coupling

wear

Twice

a

year

Noise,

vibrations

Monthly

Anchoring

quality

Yearly

Those

frequencies

are

given

for

information

only.

They

could

be

used

as

a

basis

to

the

creation

of

a

maintenance

plan

when

starting

a

new

installation.

Depending

on

installation

conditions

and

use,

the

periodicity

will

be

shortened

or

prolonged.

9.2.1

LUBRICATION

Bearing

bracket

sizes

25,

35

and

45,

are

fitted

with

lifetime

lubricated

ball

bearings

as

a

standard.

Bearing

brackets

sizes

55

and

65,

are

fitted

with

grease

lubricated

ball

bearings

and

greasing

nipples

as

a

standard

on

motor

side

and

impeller

side.

These

pumps

are

available

upon

request

with

oil

lubricated

ball

bearings.

Recommended

oil

lubricants

:

Bracket

temp.

<

80°C

Amb

Temp.

<

0°C

1500

RPM

>

1500

RPM

Type

acc.

to

DIN

51517

CL68

CL46

CL22

Kinematic

viscosity

@

50°C

[mm²/s]

61,2

to

74,8

41,8

to

50,8

19,8

to

24,2

Corresp.

Oil

type

SAE

20

et

20W

SAE

10W

Summary of Contents for NOLH series

Page 2: ...NOLH INSTALLATION ET MISE EN SERVICE FRAN AIS N M S n 4086805 Ed 3 10 13...

Page 27: ...FRAN AIS 27 Avec palier roulements lubrifi s bain d huile Montage presse toupe tresses...

Page 32: ...FRAN AIS 32 13 DECLARATION CE...

Page 33: ......

Page 34: ...NOLH INSTALLATION AND OPERATING INSTRUCTIONS ENGLISH N M S n 4086805 Ed 3 10 13...

Page 35: ...2...

Page 59: ...ENGLISH 26 Oil lubricated ball bearings Stuffing box arrangement...