MF 9841 MF 9626/9631/9841 1 – 18

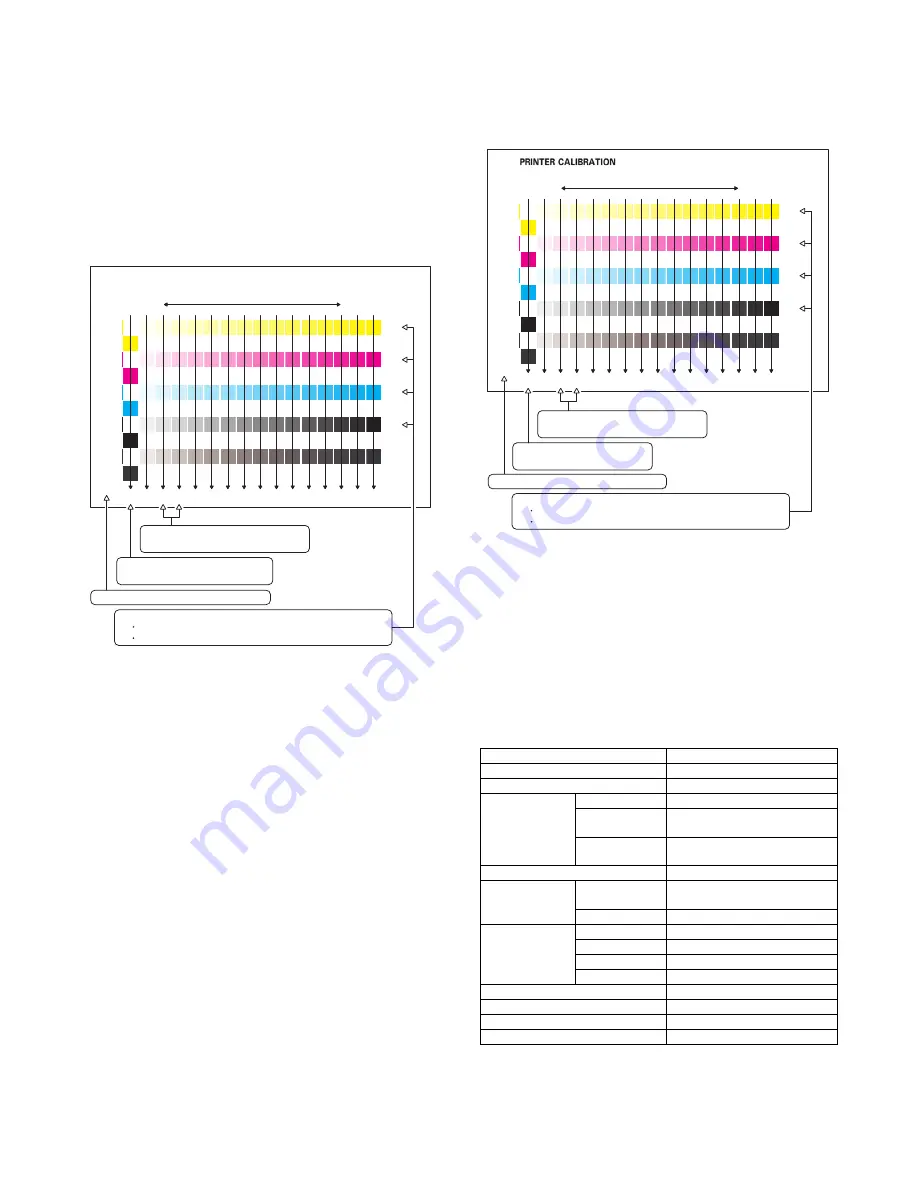

10) Check the copy color balance and density.

There are two methods to check the color balance and density.

(Method 1)

Use the servicing color test chart (UKOG-0317FCZZ/UKOG-

0317FC11) in the Text/Printed Photo mode (Manual) to check

the copy color balance and density. (Refer to the item of the

copy color balance and density check.)

(Method 2)

By printing the color balance adjustment sheet with SIM 46-21

and comparing each process (CMY) black patch color balance

with the black patch, the color balance adjustment can be

checked more precisely.

If the color balance of each patch of the process black (CMY

mixed color) is slightly shifted to Magenta, it means that the

adjustment is proper. If the color balance of the adjustment

pattern printed in this mode is slightly shifted to Magenta, it is

converted into the natural gray color balance by the color cor-

rection table in an actual copy mode. (When the color balance

target is DEF 1.)

If the automatic adjustment cannot obtain satisfactory results

of the copy color balance and density, use SIM 46-21 (ADJ

20C) (Manual adjustment).

11) Check the printer color balance and density.

There are two methods to check the color balance and density.

(Method 1)

Use SIM 64-5 to print the print test pattern and check the print

color balance and the density.

Set each setting value to the default and press [EXECUTE]

key, and the print test pattern is printed.

(Refer to the item of the printer color balance and density

check.)

(Method 2)

Use SIM67-25 to print the color balance adjustment sheet and

compare the black patch color balance of each process (CMY)

with the black patch. This procedure allows checking the color

balance adjustment result correctly.

If the color balance of each patch of the process black (CMY

mixed color) is slightly shifted to Magenta, it means that the

adjustment is proper. If the color balance of the adjustment

pattern printed in this mode is slightly shifted to Magenta, it is

converted into the natural gray color balance by the color table

in an actual printer mode. (When the color balance target is

DEF 1.)

If a satisfactory result on the print color balance and the den-

sity is not obtained with the automatic adjustment, execute the

manual adjustment (SIM 67-25) (ADJ 21B).

L. Function and operation check

Check that the following operations are normal.

;

/

%

$M

3

/CZ

1 2

0

/

.

-

,

+

*

)

(

'

&

%

$

#

CMY

Blend

High density

Low density

Patch A of each of Y, M, C, and

BK are not copied.

2) Patch C or D of each of Y, C, M, and

BK is very slightly copied.

3) Patch for each of C, M, Y, BK

The patch density is identical between patches or not reversed.

The patch density is changed gradually.

1) The max. density section is not blurred.

Check item list

Equipped condition

Key-in (operation panel)

Display (operation panel)

Paper feed

operation

Hand feed

Main unit paper

tray

Desk unit paper

feed tray

With the desk unit installed

Paper size detection

Originals size

detection

Original table

mode

RSPF mode

RSPF operation/

two sided copy

S-S mode

D-S mode

S-D mode

D-D mode

Bookbinding operation

When the finisher is installed

Stapling operation

When the finisher is installed

Grouping operation

When the finisher is installed

Sorting operation

When the finisher is installed

;

/

%

$M

3

/CZ

1

2

0

/

.

-

,

+

*

)

(

'

&

%

$

#

CMY

Blend

High density

Low density

Patch A of each of Y, M, C, and

BK are not copied.

2) Patch C or D of each of Y, C, M, and

BK is very slightly copied.

3) Patch for each of C, M, Y, BK

The patch density is identical between patches or not reversed.

The patch density is changed gradually.

1) The max. density section is not blurred.

Summary of Contents for MF 9841

Page 89: ......