O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

13

S A G E M E T E R I N G , I N C .

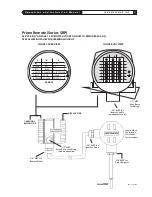

ANSI Class Flanges

(user supplied)

Largest of the

Two Perforated

Plates

Flow Conditioning

Assembly is

inserted here.

One Pipe

Diameter

FLOW

Gaskets

One Pipe

Diameter

Straight Run Requirement

from this Flange

CAPTIVE FLOW CONDITIONERS

Can Be Installed in Conjunction with Insertion Style Flow Meters

NOTE: The larger of the two perforated plates of the Sage

Flow Conditioning assembly is positioned between two flanges

and two gaskets as shown. The smaller of the two perforated

plates of the conditioner will freely slide into the application

pipe, facing downstream. The probe mounting hardware will be

placed one diameter downstream of the downstream plate.

Probe location must be one pipe ID diameter downstream of

Flow Conditioners or errors will occur.

Front View of one of the Conditioning Plates

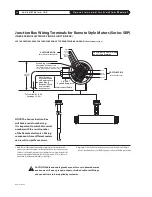

IMPORTANT The location of the probe must be exactly one pipe ID diameter (i.e., 4” in a 4” pipe; 6” in

a 6” pipe, etc.) downstream of the Captive Flow Conditioning assembly. The Captive Flow Conditioners

are always designed to be separated by one pipe diameter. See drawing below. The probe location must

be one pipe ID diameter downstream of Flow Conditioner, or errors will occur.

Note: See table on page 11

(last Column) for Straight Run

Requirement

Summary of Contents for SIP

Page 2: ......

Page 6: ......

Page 7: ...Section GETTING STARTED A...

Page 8: ......

Page 25: ...Section STYLES AND FEATURES B...

Page 26: ......

Page 32: ......

Page 33: ...Section DRAWINGS C...

Page 34: ......

Page 41: ...Section DIAGNOSTICS D...

Page 42: ......

Page 47: ...Section WARRANTIES AND SERVICE WORK E...

Page 48: ......

Page 53: ...Section MODBUS F...

Page 54: ......

Page 63: ...G Section APPENDIX G...

Page 64: ......