If your glass breaks

If your glass breaks, call your dealer for the exact replace-

ment glass and instructions on how to replace the glass

and gasket.

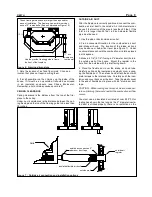

1. Remove the door from the fireplace by lifting it off the

hinges. If the right side glass needs to be replaced remove

door by removing the adjustment/mounting screws (See

Figure 1).

2. Remove the clips holding the glass in place.

3. Clean out any bits of glass and dirt from the gasket.

4. Place the new glass into the opening and replace

the clips,

being careful not to overtighten the screws

.

5. Check the glass by trying to move it back and forth. It

should feel snug, but move slightly without too much effort.

If the right glass was replaced, replace the door and adjust

it square with the centre door. See section DOORS if the

door needs adjustment.

GOLD PLATING

If you have gold doors or gold louvers, you will be happy to

know that they will not tarnish. However, they are not

scratch resistant and require a totally abrasive free clean-

ing. Use only mild soap and warm water to clean the gold

when the surface is cool. The use of any household clea-

ner, such as Windex, abrasive cleaners, or any form of

acid, may permanently etch or remove some of the gold

plating. Before every fire, be absolutely sure to wipe off all

fingerprints from the gold plating. Acid from debris or your

fingerprints may permanently etch the gold plating.

CHIMNEY CLEANING

Check the chimney for creosote buildup every month until

experience shows how often cleaning is necessary. A

buildup of 1/4 inch or more should be cleaned mechanical-

ly before more creosote accumulates. Use a plastic bristle

or wire brush that fits correctly into the chimney. The baf-

fle in the firebox can be removed to gain access to the flue

from below.

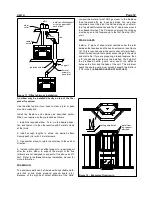

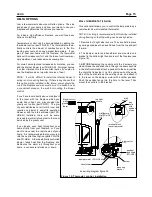

To remove the baffle, first remove the secondary air pipe.

This can be done by removing the cotter pin from the top

right side of the secondary air pipe and sliding the pipe as

far as it goes to the left. Then when the right side drops out

of its hole, slide it to the right until the other side drops. To

remove the baffle, push up and slide it off the brackets.

Replace both as you removed them and be sure the holes

on the secondary air pipe are facing toward the front.

PAINT

You may touch up the face of the Delta with STOVE

BRIGHT flat black high temperature paint. The correct

paint is available from your dealer. When you paint the

face of the fireplace, remove or cover the gold items (i.e.,

doors and louvers), and cover the area surrounding the

fireplace with newspaper. Follow the directions outlined on

the spray can. DO NOT attempt to paint while the fireplace

is still warm. Keep the spray can away from any source of

heat or open flame. Ensure that there is adequate ventila-

tion in the room from the time you start painting until the

paint is dry.

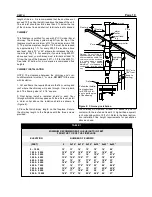

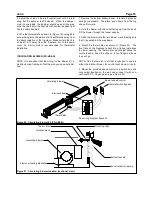

REFRACTORY BRICKS INSTALLATION

The refractories or refractory bricks for the Delta fireplace

are placed in the fireplace at the factory. If, for any reason,

they should need to be replaced the following order should

be observed.

The bottom refractory R4606 and R4605 should be placed

at the bottom of the firebox. The two rear refractories

R4602 and R4601 should then be positioned taking care to

place them as in the diagram. The two side refractories

R4604 and R4603 are then positioned once again being

careful to place them properly. If the refractories on the

back and sides do not fit immediately into position as in the

diagram they should not be forced. The refractories can

only be fitted into place as they were designed to do. The

last three refractories should be placed in front from left to

right looking at the fireplace R4608, R4609, and R4607.

These directions should be reversed in order to remove the

refractory bricks from the Delta.

Page 6

DELTA

Figure 1b: Refractory bricks installation