60

14.3 Adjustment work

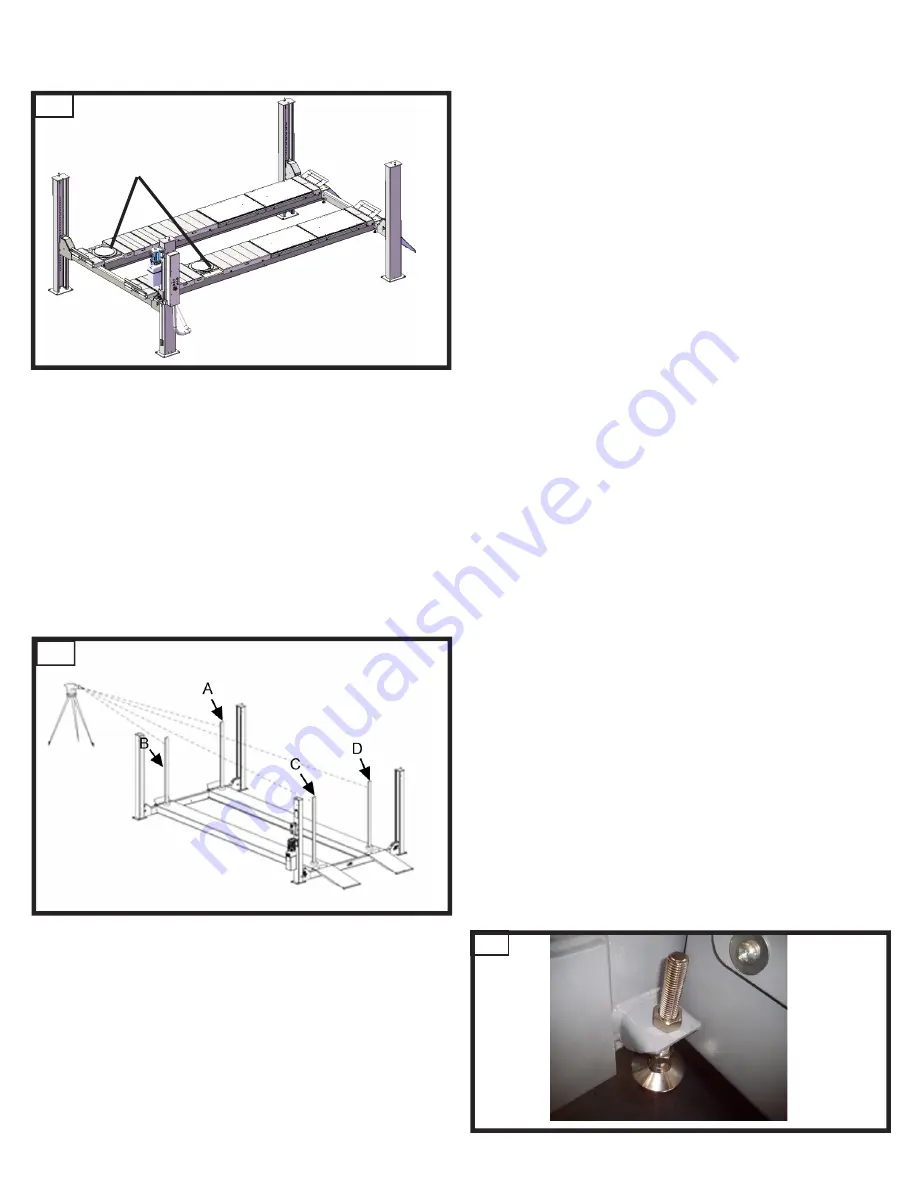

1. To begin making adjustments, first roughly level

the runways.

2. To do so, adjust the 4 cables in such a way that

the loaded runways of the lift are horizontal both

lengthwise and diagonally.

To do this, place a spirit level onto the surface

of the runway first lengthwise and then onto the

cross beam.

Turn table

55

3. Lock the lift into the latch bar.

4. Adjust the cables with the nuts on the cable end.

Then lock the nuts. Make sure that all latches are

at the same height.

Adjust the runways according to the requirements

of the vehicle manufacturer. To do so, the

following measuring equipment is required:

•

Automatic level

•

Measuring stand with scale in mm.

5. Drive the vehicle onto the lift so that the front

wheels stand on the turning radius gauge and the

rear wheels on the slip plate.

The vehicle must come to a halt virtually centered

on the lift in the direction of motion.

6. Loosen the lock pins on the turning radius gauge

and slip plates. Make sure that the vehicle can

now slip easily on the plates and that no tension

exists so that the adjustment work can be carried

out precisely.

7. Now lower the lift into the bottom position.

8. Position the automatic level so that the

measuring stands can be seen positioned one

behind the other on the wheel footprints.

9. For each wheel footprint, note the measurements

according to the scale on the measuring stand.

10. Using the 4 cross beam adjustment screws

in the "bottom position“, (

→

Fig. 46) adjust the

height so that the readings from all 4 measuring

points are the same after they have been

checked again.

57

56