CE Conformity

C-3

Cable Clamps

• Use suitable EMC-tested cable clamps only.

• The connection area must be 360 degrees around the shielded cable.

• The cable clamps also provide strain-relief for the cable.

• When using conduit, the contact point of metal entry connections must be free

of paint or non-conductive surfaces and solidly connected with good

conductivity to the enclosure.

Motor Cable

• The cable between the drive and motor must be a 4-wire shielded cable (three

phases and ground).

• Do not exceed the maximum motor cable length for the specific line filter

module used.

• Inside the shielded enclosure, shielded motor cable must be used as close to the

drive’s output terminals as possible. The shield must be solidly connected to the

PE terminal of the drive.

• Where the shielded motor cable exits the enclosure, an EMC-tested cable

clamp, or metal conduit must be used to solidly connect the cable shield to the

enclosure.

• The shield on the motor side must be solidly connected to the motor housing

with an EMC-tested cable clamp, or conduit, providing good conductivity from

the cable shield to the motor housing.

Motor Connections

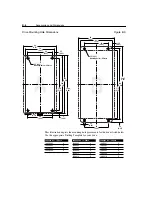

Figure C.2

Shielded Enclosure

U/T1

V/T2

W/T3

= EMC Tested Shielded Cable Clamp (or Metal Conduit)

Motor Wiring

TB2

DC+

W/T3

1

3 4 5 6 7 8 9 10 11

2

V/T2

U/T1

DC–

BR+

T/L3

S/L2

R/L1

BR–

FAULT

READY

Ground Terminal – PE

4 Wire Shielded Motor Cable

Ground to Motor Housing

Summary of Contents for Allen-Bradley 160 SSC Series

Page 12: ...1 6 Getting Started End of Chapter ...

Page 58: ...5 20 Parameters and Programming End of Chapter ...

Page 66: ...A 4 Specifications End of Chapter ...

Page 75: ...Accessories and Dimensions B 9 Drilling Template A Figure B 10 ...

Page 76: ...B 10 Accessories and Dimensions Drilling Template B Figure B 11 ...

Page 82: ...C 6 CE Conformity End of Chapter ...

Page 87: ......