IDENTIFYING/INSTALLING PERMANENT FLOOR SUPPORTS

GENERAL INSTALLATION INFORMATION

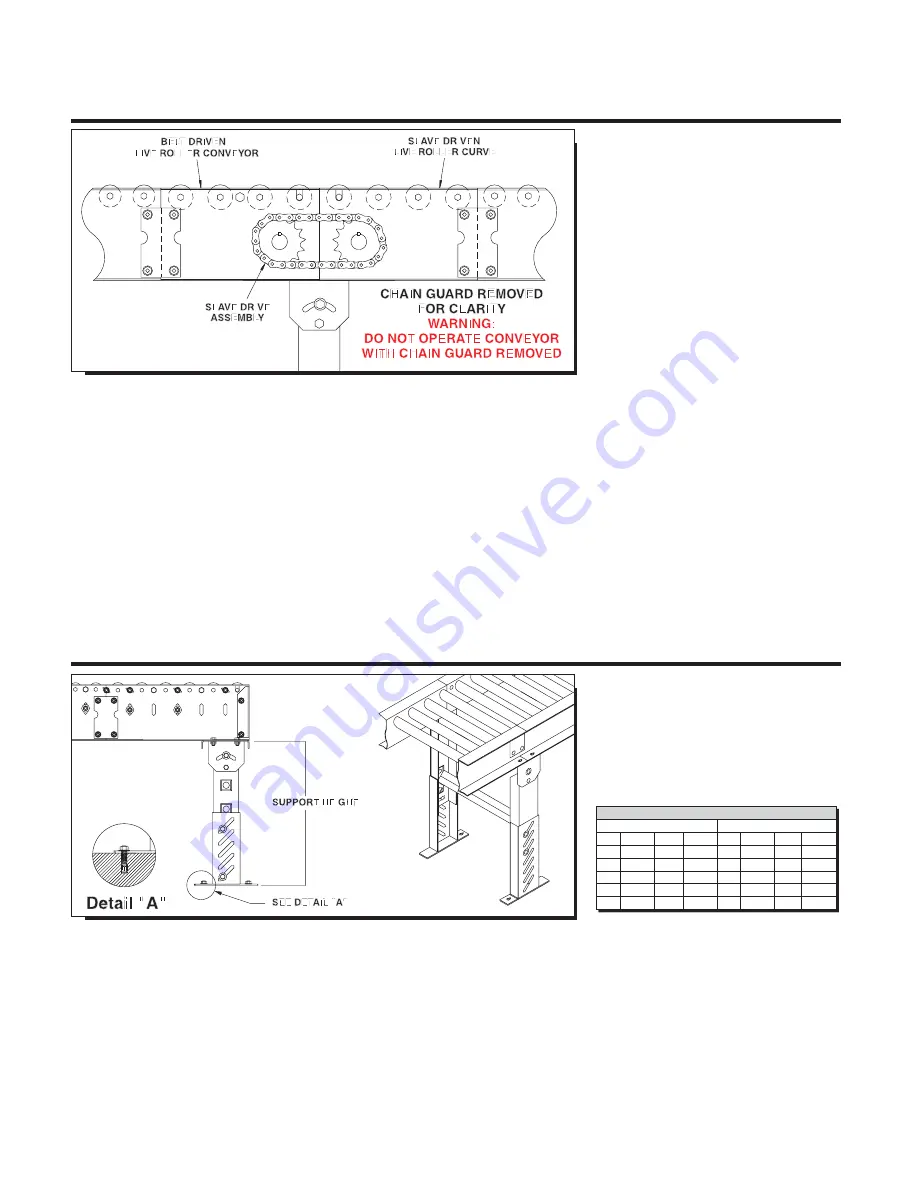

SLAVE DRIVE / MATING TO OTHER CONVEYORS

NOTE:

There are two primary methods of

installation for a curve--driven by its own

gear motor or SLAVE driven from another

conveyor.

Once conveyor is uncrated, installation of

curve or spur may begin (note that in follow-

ing text we will use “curve” for reference to

both curves and curve spurs). Locate unit in

the actual installation area.

There are two primary methods of instal-

lation for a curve--driven by its own gear

motor or SLAVE driven from another con-

veyor. Most often, curves are SLAVE driven

by belt driven live rollers or slider bed belt

conveyors, which eliminates gear motor

drive assembly for curve.

Locate actual bed section of conveyor

which is to slave drive curve to begin instal-

lation. Note that this conveyor is usually

set up before curve is installed. Bed sec-

tion labels are located on bed of driving

conveyor showing where slave driven curve

will be installed (see illustration above). For

curves not slave driven, location of instal-

lation in most usually noted by conveyor

“mark numbers”.

Use mechanical hoist (fork truck or other

available means) to raise bed sections to

approximate installed elevation. Locate sup-

ports, attach to curve and mate curve with

butt couplings.

It is most common to use single tier perma-

nent floor supports at each end of a curve,

for models 138LRC and 196LRC. In the

center of the curve, a single leg support is

required underneath the outside frame rail.

If the frame rail consists of two or more

frame rails

and

is joined together in the cen-

ter of the curve, a full support is required.

For model 138LRCS and 196LRCS curve

spurs, two supports are generally required,

one support at the junction between the

spur and the curve and one support at the

tangent end of the curve.

Adjust elevation to top of conveyor by

loosening bolts in support uprights, raising

or lowering conveyor and fully tightening

bolts at desired elevation. Tighten all bolts

in supports

before

unit operation.

Complete support installation by lagging

support attachment plates to floor with two

lag bolts in a diagonal pattern in support

foot plate mounting holes. Conveyor

must be level across width of unit before

completing final support height adj.

*Supports are normally shipped at minimum

support height. See chart above.

CAUTION: Always

anchor permanent sup-

ports to floor (or mounting surface). Use

3/8” x 2-1/2” (or longer) wedge anchors

for permanent installation in

concrete flooring.

*MINIMUM SUPPORT HEIGHT

MEDIUM DUTY

HEAVY DUTY

SM-1

7-1/4”

SM-7

34-1/4” SH-1

6-1/4”

SH-7

25-3/4”

SM-2 10-1/4”

SM-8

46-1/4” SH-2

7-3/4”

SH-8

31-3/4”

SM-3 13-1/4”

SM-9

58-1/4” SH-3 10-3/4”

SH-9

43-3/4”

SM-4 16-1/4” SM-10 70-1/4” SH-4 13-3/4” SH-10 55-3/4”

SM-5 20-1/4” SM-11 80-1/4” SH-5 16-3/4” SH-11 67-3/4”

SM-6 24-1/4” SM-12 92-1/4” SH-6 19-3/4” SH-12 29-3/4”

5

Summary of Contents for 138LRC

Page 1: ......

Page 9: ...V BELT PATHS V BELT PATH FOR SPURS AND CURVES 9...

Page 17: ...MODEL 138LRC ILLUSTRATIONS FOR UNIT WITH END DRIVE SIDE MOUNT END DRIVE 17...

Page 19: ...MODEL 196LRC ILLUSTRATIONS FOR UNIT WITH END DRIVE SIDE MOUNT END DRIVE 19...

Page 21: ...MODEL 138LRCS ILLUSTRATIONS FOR UNIT WITH END DRIVE SIDE MOUNT END DRIVE 21...

Page 23: ...MODEL 196LRCS ILLUSTRATIONS FOR UNIT WITH END DRIVE SIDE MOUNT END DRIVE 23...