PUB. NO. DFNDRB JANUARY 2013

19

DEFENDER

™

FEATURE RICH - ENCODER SETUP / PROGRAMMING

ENCODER SETUP INSTRUCTIONS

1.

Verify wiring to encoder is properly terminated.

Note: right-hand drive doors require a RED wire to be

terminated in the ‘DC’ terminal, while left-hand drive doors

do not. If motor phase is changed during this setup,

please restart this procedure.

2.

Move curtain to closed position.

3.

Power up door and press enter button to enter

“MAIN MENU”.

4.

Using down arrow, scroll to

“Open Distance”.

5.

Press enter button to view parameter value (measured in

feet), should be O.D.H. - (two) 2’ [610]. Change the value

using the up or down arrow keys, round down if required,

then press enter to return to

“MAIN MENU”.

6.

Scroll using down arrow to item

“Set Close Pos.”

.

7.

Press enter button to view parameter. The controller will

display the following message “RESET ALL LIMITS” …

“Press Up to Start”.

Pressing the up arrow key will reset

all of the limits, and reboot the controller.

NOTE: DO NOT use this menu item to make

adjustment to the limits; this is only for initial setup.

8.

Press green Open/Reset button.

a. The door should begin to open, be ready to shutdown

the door if it begins to move in the wrong direction. If

motor phase is changed, start over at step #2.

b. If rotation is correct proceed to the instructions for

adjusting the “Open and Close positions”.

Open and Close Position Adjustment

To adjust CLOSE position:

1.

Power up door and press enter button to enter

“MAIN

MENU”.

2.

Scroll using up arrow to the item

“Close Pos. Adjust”.

3.

Press enter button to view parameter value. This

parameter will show a coded value on the left and relative

change in inches on the right. When entering this

parameter the value will always start at 0.0”.

Change values using the up or down arrows.

To bring the curtain closer to the floor, adjust this value so

that it is less than zero. (i.e. To close the door 4” [102]

more, the value for

“Close Pos. Adjust”

will be -4.0”

[102]) Moving this parameter in the positive direction

raises the curtain relative to the floor. Changing this value

will not affect the open position.

Note: If you leave this parameter and return to it, its value will

again be zero. Any changes made before leaving the

parameter will still be effective. For example: If you

lowered the door 4.0”, leave the parameter and return, the

parameter will display 0.0”. Even though the display

shows 0.0” the -4.0” change has been recorded.

4.

When parameter is changed press enter button for three

(3) seconds to return to the

“MAIN MENU”.

5.

Test operation of door and continue adjustment.

TIP: At any point in the menu mode, Pressing and holding the

enter button for at least 2 seconds will cause the

controller to automatically accept all the changes made

and exit the menu system.

To adjust the OPEN position:

1.

Power up door and press enter button to enter

“MAIN MENU”.

2.

Using up arrow key, scroll to

“Open Pos. Adjust”.

3.

Press enter button to view parameter value. This

parameter will show a coded value on the left and the

opening height in inches on the right. This value will

always be less than the door opening height.

Change the value using the up and down arrow keys.

To bring the open position down (closer to the floor)

adjust this value to be less than the current value. To

open the door more relative to the floor, adjust this

parameter in a positive direction. (i.e. To open the door 4”

more, and the current value is 72.0” [1829]. Change the

value for

“Open Pos. Adjust”

to be 76.0” [1930]).

Changing this value will not affect the close position.

4.

When parameter is changed press enter button for three

(3) seconds to return to the

“MAIN MENU”.

5.

Test operation of the door, and continue adjustment.

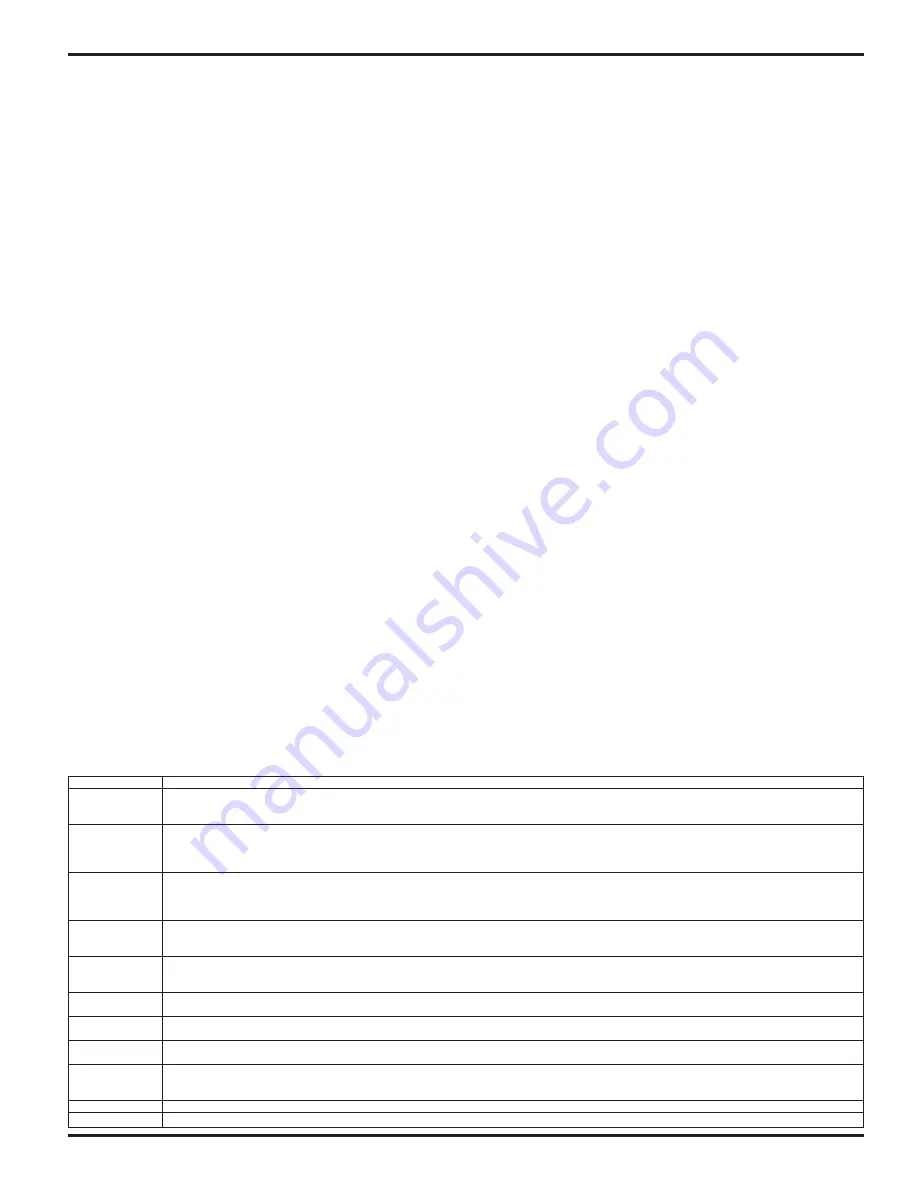

OPTION

DESCRIPTION

Open Distance

Use this option to set the overall opening distance of the door (in feet). For example, for an 8’ tall Defender. This option should

be set to 7’ [178]. This measurement is used for initial position setup only. For small adjustments of the open and close position,

use “Close Position Adjust” or “Open Position Adjust”

Set Open Pos

Use this option for initial position setup. Manually place door in the open position and select this option. Alternatively “Set Close

Pos.” can be used if it is more convenient to place the door in the closed position.

NOTE: This option approximately sets the open and close positions.

For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust”

Set Close Pos

Use this option for initial position setup. Manually place door in the close position and select this option. Alternatively “Set Open

Pos.” can be used if it is more convenient to place the door in the open position.

NOTE: This option approximately sets the open and close positions.

For additional adjustment of the open and close position, use “Close Position Adjust” or “Open Position Adjust”

Open Pos Adjust Use this option to make small adjustment to the open position. The number displayed is the measurement between the open and

closed position. For example if this option was set to 100” [2540] the door would open 100 inches from the closed position.

It is recommended to adjust the closed position of the door first, before adjusting the open position.

Close Pos Adjust Use this option to make small adjustment to the closed position. The number displayed is the relative displacement of the closed

position. For example, if this option was set to -1.0”[-25] the door would close approximately 1.0” [25] more.

If this option was set to 2.0” [51] the door would close 2.0” [51] less.

Apr Open Pos

Use this option to adjust the approach open position. This option is a measurement in inches from the open position. For

example, if this option was set to 24.0” [610] the door would slow down 24.0” [610] from the open position.

Encoder Startup The controller is waiting for valid data from the encoder. It the controller does not receive a response at startup, this will remain

on the screen indefinitely. If this does not clear with 5 seconds, please check all encoder wiring.

Encoder Read

The controller is unable to read valid data from the encoder. Check all wiring. Ensure that the shield on the encoder cable is

connected to ground, and that the control box is grounded. The error requires the power to be cycled to reset.

Encoder Velocity The controller has received a signal from the encoder that the door is moving faster than allowed. This can occur if the encoder

is not properly attached to the shaft, bad electrical connection to the i-COMM, or improper grounding.

The error requires the power to be cycled to reset.

Open Time Limit Door tried to run, but did not reach the open or close position within 8 seconds.

Photoeye Failure Non-Drive PE’s must have green light on, drive PE’s must have red & yellow lights on. Check for alignment & power to each.

Summary of Contents for FROMMELT SAFETY PRODUCTS GUARDIAN DEFENDER

Page 4: ...4 PUB NO DFNDRB JANUARY 2013 DEFENDER GUIDE BASE PLATE POSITIONS ...

Page 18: ...18 PUB NO DFNDRB JANUARY 2013 DEFENDER FEATURE RICH I COMM SETTINGS ...

Page 45: ...PUB NO DFNDRB JANUARY 2013 45 DEFENDER ARCHITECTURAL DRAWING DIRECT DRIVE ...

Page 46: ...46 PUB NO DFNDRB JANUARY 2013 DEFENDER ARCHITECTURAL DRAWING DIRECT DRIVE II ...

Page 47: ...PUB NO DFNDRB JANUARY 2013 47 DEFENDER ARCHITECTURAL DRAWING CHAIN DRIVEN ...