2916050

36

GB

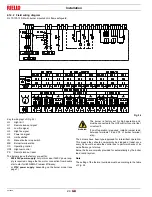

Faults - Probable causes - Solutions

Symbol

(1)

Fault

Probable cause

Suggested remedy

The burner does not start

A limit or safety control device is open

Adjust or replace

Control box lock-out

Reset control box

Oil pressure switch tripped

Adjust pressure switch or eliminate

pressure

Motor protection tripped

Reset thermal cut-out

No electrical power supply

Close all switches - Check connections

Flame safeguard fuse blown

Replace

Contact II of servomotor does not operate,

flame safeguard terminals 11 - 8

Adjust cam II or replace servomotor

Pump is jammed

Replace

Defective motor command control device

Replace

Defective Flame safeguard

Replace

Defective electrical motor

Replace

The burner does not start and a

function lock-out occurs

Flame simulation

Replace control box

Photocell short-circuit

Replace photocell

Missing phase thermal cut-out trips

Reset thermal cut-out when third phase is

re-connected

The burner starts but stops at

maximum air damper setting

Contact I of servomotor does not operate,

flame safeguard terminals 9-8

Adjust cam I or replace servomotor

The burner starts and then goes

into lock-out

Fault in flame detection circuit

Replace flame safeguard

The burner remains in pre-

purging phase

Contact III of servomotor does not operate,

flame safeguard terminals 10-8

Adjust cam III or replace servomotor

After pre-purge and the safety

time, the burner goes to lock-out

and the flame does not appear

No fuel in tank; water on tank bottom

Top up fuel level or suck up water

Inappropriate head and air damper

adjustments

Adjust

Light oil solenoid valves fail to open

Check connections; replace coil

Nozzle clogged, dirty, or deformed

Replace

Dirty or poorly adjusted firing electrodes

Adjust or clean

Grounded electrode due to broken

insulation

Replace

High voltage cable defective or grounded

Replace

High voltage cable deformed by high

temperature

Replace and protect

Ignition transformer defective

Replace

Poor electrical connections of valves or

transformer

Check

Defective flame safeguard

Replace

Pump unprimed

Prime pump and see "Pump unprimes”

Pump/motor coupling broken

Replace

Pump suction line connected to return line Correct connection

Valves up-line from pump closed

Open

Filters dirty: line - pump - nozzle

Clean

Incorrect motor rotation direction

Change motor electrical connections

The flame ignites normally but

the burner locks out when the

safety time has elapsed

Defective flame sensor or flame safeguard Replace flame sensor or flame safeguard

Dirty flame sensor

Clean

1