Maintenance

33

2916050

GB

Flame inspection window

Clean the flame inspection window (Fig. 44).

Flame sensor

Clean the glass cover from any dust that may have accumulated.

flame sensor 1)(Fig. 45) can be removed by pulling it outward

forcefully.

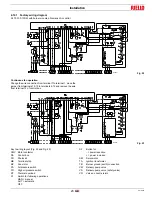

Servomotor

Disengage the cam (Fig. 34 on page 28) from the servomotor and

turn it backwards and forwards by hand to make sure it moves free-

ly.

Nozzles

It is advisable to replace nozzles once a year during periodical

maintenance. Do not clean the nozzle openings;

Hoses

Check that these are in good conditions.

Pump

The pump delivery pressure must be stable at 290 PSI.

The suction must be less than 6.5 PSI.

Unusual noise must not be evident during pump operation.

If the pressure is found to be unstable or if the pump runs noisily,

the flexible hose must be detached from the line filter and the fuel

must be sucked from a tank located near the burner. This measure

permits the cause of the anomaly to be traced to either the suction

line or the pump.

If the pump is found to be responsible, check to make sure that the

filter is not dirty. The vacuum gauge is installed up-line from the fil-

ter and consequently will not indicate whether the filter is clogged

or not. If the problem lies in the suction line, check to make sure

that the filter is clean and that air is not entering the piping.

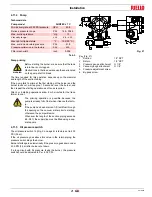

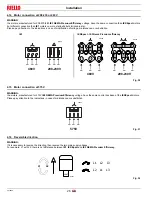

Filters

Check the following filters: on line 1), in pump 2), at nozzle 3), and

clean or replace as required (Fig. 46).

If rust or other impurities are observed inside the pump, use a sep-

arate pump to suck out any water and other impurities that may

have deposited on the bottom of the tank.

Burner

Make sure that the screws securing the electrical leads in the burn-

er connections are fully tightened.

Clean the outside of the burner, taking special care with the linkag-

es joints and cam.

Fuel tank

Approximately every 5 years, suck any water on the bottom of the

tank using a separate pump.

Fig. 44

D709

Fig. 45

D709

D1232

D707

Fig. 46