Installation

17

2916050

GB

4.7.4

Adjusting the nozzle flow rate

The nozzle flow rate varies according to the fuel pressure on the

nozzle return.

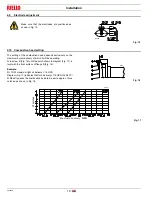

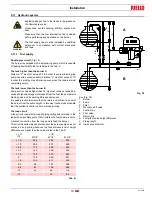

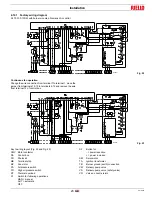

Diagram (Fig. 13) indicates this relationship for type A4 return flow

nozzles with pump delivery pressure of 290 PSI.

NOTE:

with a pump delivery pressure of 290 PSI, the pressure on the

nozzle return must not exceed 246.5 PSI.

The pressure difference between pump delivery and nozzle return

must be at least 43.5 PSI. With smaller pressure differences, the

pressure on the nozzle return can be unstable.

4.8

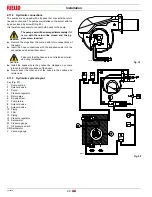

Pressure controller

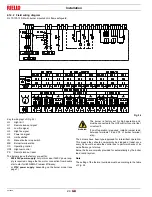

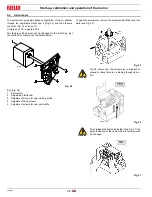

The nozzle return pressure value is indicated by the pressure

gauge 1)(Fig. 14).

The output and the pressure of the nozzle are at maximum when

the servomotor is positioned on maximum.

The fine adjustment of the pressure in the return line may be

carried out by changing the setting of the eccentric 6)(Fig. 14),

of the nut and lock-nut 4)(Fig. 14).

The eccentric setting should be carried out by loosening

screws 7), and turning the screw 5) to obtain the desired

eccentricity.

Turn clockwise, screw 5) to increase the eccentricity, increas-

ing the difference between the min. and max. capacity of the

nozzle.

Turn counter-clockwise, screw 5) to decrease the eccentricity

and, consequently the difference between the min. and max.

capacity of the nozzle.

When the setting is carried out, verify manually that no slow-down

occurs between 0° and 130° and that the maximum and minimum

pressures correspond to those chosen as per diagrams (Fig. 13).

If you wish to check the delivery capacity of the nozzle, open the

burner, attach the nozzle, simulate the start-up and then proceed

with observing of the maximum and minimum pressures of the fuel.

If at the maximum capacity of the nozzle (maximum pressure in the

return line) pressure fluctuations are detected on the gauge 1),

slightly decrease the pressure in the return line until they are com-

pletely eliminated.

Gauge for pressure in return line

2

Oil pressure switch

3

Ring for piston stop

4

Nut and lock-nut for piston setting

5

Eccentric adjusting screw

6

Variable eccentric

7

Eccentric locking screws

WARNING

The proper setting of the eccentric 6) is possible

when its operation field follows the servomotor op-

eration field (20°-130°): so, that every variation of

the servomotor position corresponds to a pressure

variation.

CAUTION

Do not let the piston bottom out repeatedly: the stop

ring 3)(Fig. 14) determines the max. stroke.

D1227

Fig. 14