E

N

G

L

I

S

H

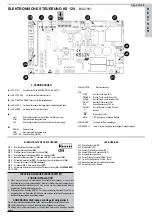

5 – CONTROL OF THE MOTOR ROTATION DIRECTION

This control is carried out to facilitate the installation of the system or any possible future

control.

1 -

After you positioned the limit switch cams on the rack, (Fig.7 page 4)

, set Dip1 on

mode ON. The LED DL5 starts blinking.

2 - Press and keep the button PROG. (the gate is now controlled with manned operation:

open-stop-close-stop-open-etc.).

THE GREEN LED DL6 “OPEN” turns on and the

gate opens and stops after having reached the limit switch cams.

If this does not

happen, release the button and invert the two cables of the motor.

3 - Press the button PROG. and keep it.

THE RED LED DL7 “CLOSE” turns on and the

gate closes and stops after it reaches the limit switch cams.

4 -

At the end of the control, position DIP1 on mode OFF

. The LED DL5 turns off,

signalling you exit from the control.

NB: The encoder and the photocells are not active during this control.

6 - TIMING

PROGRAMMING

The programming can be carried out regardless of the gate position.

1 - Position the micro switch Dip 2 on mode ON => The LED L1 emits short blinkings

2 - Push button PROG. => the gate closes. 2 seconds after the gate closed, it opens

automatically. When the opening cycle Is concluded, the gate stops. Wait as long as you

want the gate to remain open (excluded by DIP3 OFF)

3 - Push button PROG. to operate the gate closing (also the pause time count stops

before the automatic closing - max. 5 minutes).

4 - The gate stops when the closing cam is reached.

5 - Position Dip 2 back on mode OFF when the programming is concluded.

COMMAND ACCESSORIES OPERATION

OPENING BUTTON (with timer function) COM-OPEN

When the gate is standstill, the button controls the opening movement. If the button Is

operated while the gate Is closing, It opens the gate again.

TIMER FUNCTION

This function can be useful in rush hours, when vehicle traffic is slow (e.g. entry/exit of

workers, emergencies In residential or parking areas, and, temporary, for removals).

APPLICATION MODES

If you connect a switch and/or a daily/weekly timer (at place or in parallel to the opening

button N.O. “COM-OPEN”), you can open the automation and keep it open as long as the

switch is operated or the clock is activated.

When the automation is open, all operating functions are inhibited.

If the automatic closing Is selected, the automation Immediately closes when the switch Is

released or at the time previously set; If not, you need to use a command.

CLOSING BUTTON (COM-CLOSE)

It operates the closing movement when the gate is standstill.

JOGGING OPERATION BUTTON (COM-K BUTTON)

If DIP5 is OFF => It cyclically commands open-stop-close-stop-open-etc.

If DIP5 is ON => It opens the gate when this is closed. If this button Is operated while the

gate Is opening, It has no effect. It closes the gate If Is operated when this Is open and

opens the gate If Is operated while this Is closing.

RADIO TRANSMITTER

If DIP4 is OFF => It cyclically commands open-stop-close-stop-open-etc.

If DIP4 is ON => It opens the gate when this is closed. If It Is operated while the gate Is

opening, It has no effect. If It Is operated when the gate Is open, It closes the gate. If It Is

operated while the gate Is closing, it opens the gate again.

AUTOMATIC CLOSING

Pause times before the automatic closing of the gate are set with the timing procedure.

The max. pause time is 5 minutes.

DIP3 (ON started) can start or stop the pause time.

SAFETY ACCESSORIES OPERATION

SAFETY ENCODER (KPLUS)

It serves as a safety device both when the gate is opening and when it is closing,

with movement reversal.

DIP 7 (ON) enables the motor operation with encoder.

If the Encoder does not work (due to power supply failure, disconnected wires, broken or

defective disk), the gate Is not operated.

If the encoder operates the opening or the closing and than gives a reverse command, the

gate stops and than reverses Its movement for 1 second.

The buzzer is operated to

signal the alarm 5 minutes long and the blinker blinks one minute long.

During and after the 5 minutes when the buzzer alarms, you can make the gate work

again, just pressing the operating button you want.

PHOTOCELL 1 (COM-PHOT 1)

They work when Dip 6 is operated.

If Dip 6 is OFF

- When the gate is closed, It does not open if there is an obstacle within

the photocells range of action.

During operation, photocells work both when the gate opens (by starting the opening

movement after half a second), and when It closes (by starting the reverse movement

after one second).

If Dip 6 is on mode ON

- If an obstacle is present within the photocells range of action

when the gate is closed and Its opening Is commanded, the gate opens (during the

opening movement, photocells do not work).

Photocells work only during the gate closing (by starting the reverse motion after one

second, even if they are still engaged).

STOP BUTTON

The STOP button stops the gate during any operation.

If you push It when the gate Is totally open (or partly open, by using the pedestrian

command), this button temporary excludes the automatic closing (If selected by DIP3 and

DIP9). It Is than necessary to operate another command to make the gate close again.

The automatic closing function is enabled again the following opening cycle (If selected by

DIP3 and DIP9).

BLINKER

N.B.: This electric board can supply power only to BLINKERS WITH (ACG705

7

)

BLINKING CIRCUIT, with max. 10W lamps.

PRE-BLINKING FUNCTION:

- With DIP8 on ON

=> The motor, the blinker and the buzzer start at the same time.

- With DIP 8 on OFF

=> The blinker and the buzzer start 3 seconds before the motor.

BUZZER (Optional)

The buzzer emits an intermittent sound signal during opening and closing cycles.

When safety devices are operated (alarm), the intermittence frequency of this sound

signal increases.

WARNING LIGHT - GATE OPEN (COM-SIGNAL):

Its function Is to signal when the gate Is open, partly open or not totally closed anyway. It

turns off only when the gate Is totally closed.

This signal is not enabled during the programming procedures.

N.B.: If push button panels or lamps are overused, the logic system of the control

board will be compromised, resulting into a possible operation block.

TECHNICAL DATA

- Temperature range

0 ± 70°C

- Moisture

< 95% without capacitor

- Power supply voltage

230V~ or 120V~ ±10%

- 12Vac transformer power supply

- Frequency

50/60 HZ

- Max. power consumption of the card, loadless 120 mA

- Transient mains power drops

100mS

- Max. capacity of the warning light - gate open

3 W (corresponding to 1 3W lamp or to 5

LEDS with 2,2 kΩ resistance In

series)

- Max. load at the blinker output

10W 12Vdc

- Available current for photocells and accessories 1A 12Vdc

- Available current on the radio connector

200mA 12Vdc

- Battery power supply

10,2÷13Vdc

- Transformer capacity

180VA

- All inputs must be used as clean contacts, without being earthed, because the power

supply is generated in the card and is arranged so as to allow for double or reinforced

Insulation with respect to live parts.

All inputs are controlled by a programmed integrated circuit that carries out a self-control

cycle every time the gate is operated..

OPTIONALS

EXTRA FUNCTIONS

EXPANDER 12V

CARD (ACG5471)

!! FEED THE EXPANDER 12V CARD IN WHEN POWER IS NOT SUPPLIED !!

CAPTION

TR

=>

Adjustment trimmer for the courtesy light time

1-2

=>

12Vdc power supply for photocells, FOTOCOSTA units, etc….

3-4

=>

Traffic light 1 contact

5-6

=>

Traffic light 2 contact

7-8

=>

Courtesy light contact

Pag. 18 di 28