MAINTENANCE

RC115/118/120/125 02/12

Maintenance Section 5-3

© 2012 Alamo Group Inc.

MAINTENANCE

LUBRICATION INFORMATION

Before operating your Implement, take the time to inspect and repair any damage to the machine or tractor.

Only a minimum of time and effort is required to maintain this machine to provide long life and trouble free

operation.

Lubricate the PTO shaft slides and all universal joints every 8 hours. Grease all bearings and grease points

before operating shredder and after every 8 hours of operation.

The gearbox is shipped with the proper amount of Multi-Purpose Gear Oil P/N 00786250 . Check the level of

the gearbox. The oil level should reach the mark on the dip stick attached to the breather. Do not overfill, as

this will damage the seals. The gearbox lubricant should be changed after 100 hours of operation and every

1000 hours of operation thereafter. The gearbox requires approximately 5 quarts of lubricant.

LUBRICATE SHREDDER BEFORE INITIAL USE. Lubricate all locations indicated every 8 hours with a clean,

N.L.G.I #2 grease. Wipe off fittings and end of grease gun before attaching grease gun.

The wheel bearings should be inspected and re-packed yearly.

Before each day's use, follow this procedure:

1. Visually check the unit and make certain all items are properly tightened.

2. Check the rotor shaft to make certain it is fully knifed. Replace any missing knives, then run the unit at full

speed to check for vibrations. Do not operate the unit in an out-of-balance condition.

Before doing maintenance, turn off power and securely block up shredder.

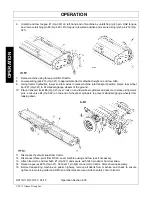

The RC flail is fitted with seven U-joints: two on the main driveline from the tractor, two on either side of the

gear box, and one on each side by the adjustment tube.

On pull type models there are nine bearings which require regular maintenance: two center bearings between

cutter-shafts, two at either end of the machine which are fitted with external grease lines, one on the jack-shaft

support bearing, and one on each top drive which is accessed through the top drive shield.

Other grease points include: one on either end of the wheel bar support tube; one on the center wheel bar

support; one on each wheel hub, and one on the ratchet screw jack

For the semi-mount units there are three additional grease points for each caster wheel assembly: one on the

caster pivot and two on the adjusting ratchet jack.

Each bearing assembly houses a double row spherical Roller bearing and requires regular lubrication, once

every eight hours.

Lubricate center bearing from rear only. Never raise machine on three point to service and

always block machines before attempting any servicing or inspection underneath.

PARTS INFORMATION

Rhino mowers use balanced and matched system components for blade carriers, blades, cuttershafts, knives,

knife hangers, rollers, drivetrain components, and bearings. These parts are made and tested to Rhino

specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit”

parts may reduce mower performance, void warranties, and present a safety hazard. Use genuine Rhino

mower parts for economy and safety.

(SPRM-1)

SEE YOUR RHINO DEALER

Summary of Contents for RC 115

Page 6: ......

Page 10: ......

Page 11: ...Safety Section 1 1 2012 Alamo Group Inc SAFETY SECTION...

Page 28: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 18 2012 Alamo Group Inc SAFETY...

Page 29: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 19 2012 Alamo Group Inc SAFETY...

Page 30: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 20 2012 Alamo Group Inc SAFETY...

Page 31: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 21 2012 Alamo Group Inc SAFETY...

Page 32: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 22 2012 Alamo Group Inc SAFETY...

Page 33: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 23 2012 Alamo Group Inc SAFETY...

Page 34: ...SAFETY RC115 118 120 125 02 12 Safety Section 1 24 2012 Alamo Group Inc SAFETY...

Page 36: ......

Page 37: ...Introduction Section 2 1 2012 Alamo Group Inc INTRODUCTION SECTION...

Page 42: ......

Page 43: ...Assembly Section 3 1 2012 Alamo Group Inc ASSEMBLY SECTION...

Page 48: ......

Page 49: ...Operation Section 4 1 2012 Alamo Group Inc OPERATION SECTION...

Page 88: ......

Page 89: ...Maintenance Section 5 1 2012 Alamo Group Inc MAINTENANCE SECTION...

Page 108: ...MAINTENANCE RC115 118 120 125 02 12 Maintenance Section 5 20 2012 Alamo Group Inc MAINTENANCE...

Page 109: ......

Page 122: ...Secci n de Seguridad 1 1 2012 Alamo Group Inc SECCI N DE SEGURIDAD...

Page 123: ......