25

SSCBL-RPBL-IOM (10-22) 149159-C

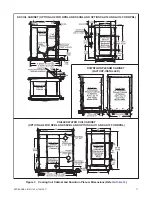

100% Outside Air Hood (Model RPBL with Option AS2)

⚠ CAUTION ⚠

It is recommended that the inlet to the outside air hood NOT be facing into the prevailing wind.

Allow a minimum clearance of 14 inches (356 mm) from the bottom of the air hood to the mounting

surface.

Option AS2 is a weatherized, screened hood designed to be field-assembled and installed around the horizontal

inlet air opening of the blower cabinet . The air hood includes factory-assembled louvers designed to help eliminate

moisture from the inlet air . Complete installation instructions are packaged with the air hood and are listed in

Screened Air Hood for 30% Outside Air Opening (Model RPBL with Option AR6 or AR7)

The outside air hood included in the air inlet options that have a 30% outside air opening (options AR6 and AR7) is

shipped separately for field-installation . Complete installation instructions are packaged with the air hood and are

listed in

Evaporative Cooling Module (Option AS3, AS4, AS5, or AS8)

The evaporative cooling module is factory-assembled, installed and wired . No additional roof mounting is necessary .

Refer to the installation manual listed in

to field-connect the water supply and to make necessary checks

and adjustments before operating the cooling module .

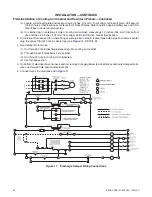

Discharge Air Temperature Sensor Installation

1 . Determine distance of sensor from unit:

a . Ensure that there is sufficient distance from outlet to have good mixture of discharge air temperature .

NOTES:

• According to the latest edition of AMCA Standard 201, in straight ducts, the air is typically well

mixed a minimum of five equivalent duct diameters from the discharge of the unit with equivalent

duct diameter defined as equal to the square root of 4AB/3.14 (A and B are duct cross-sectional

dimensions).

• Locate the sensor a minimum of 96 inches (2,435 mm) from the outlet of the unit.

• If the length of the discharge duct is less than 8 feet (2.4 meters), a mixing vane is recommended

for mixing the discharge air. Do not mount the sensor in the ductwork after a split in the supply

as this will cause loss of control in the duct that does not house the sensor.

b . Refer to following formula for calculating sensor placement . This example assumes cross-sectional dimensions

for supply ductwork of 24

×

12 inches (610

×

305 mm):

5

𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒

𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒

𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑

×

�

4 × 12 × 24

3.14

= 96

𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑ℎ𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑

5

𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒

𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒

𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑

×

�

4 × 305 × 610

3.14

= 2435

𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑒𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑

2 . Determine orientation of sensor:

a . In horizontal ductwork, position sensor in top-middle of duct with sensor probe extending vertically down into

center of air stream .

b . In vertical ductwork, position sensor in middle of duct that corresponds with top-middle of discharge outlet .