Page 9

Motor Installation

Real Carriage Door & Sliding Hardware Copyright 2020© all rights reserved

10. Check clearance and movement by swinging

door slowly

11. Relock the motor (take out of manual release

mode)

12. Repeat these steps for the other leaf, if installed

Wiring the Motor

1. Locate the stress relieving cord-grip

2. Attach connecting nut (F) to grip body (G).

Tighten securely using finger pressure only

3. Slip compression nut (H) over a length of 16/3

(16 Gauge, 3 strand) motor wire and thread wire

through the assembled cord-grip

4. Tighten the compression nut (H) with finger

pressure only

5. Refer to Wiring Simplified for wiring from motor

to control board terminals

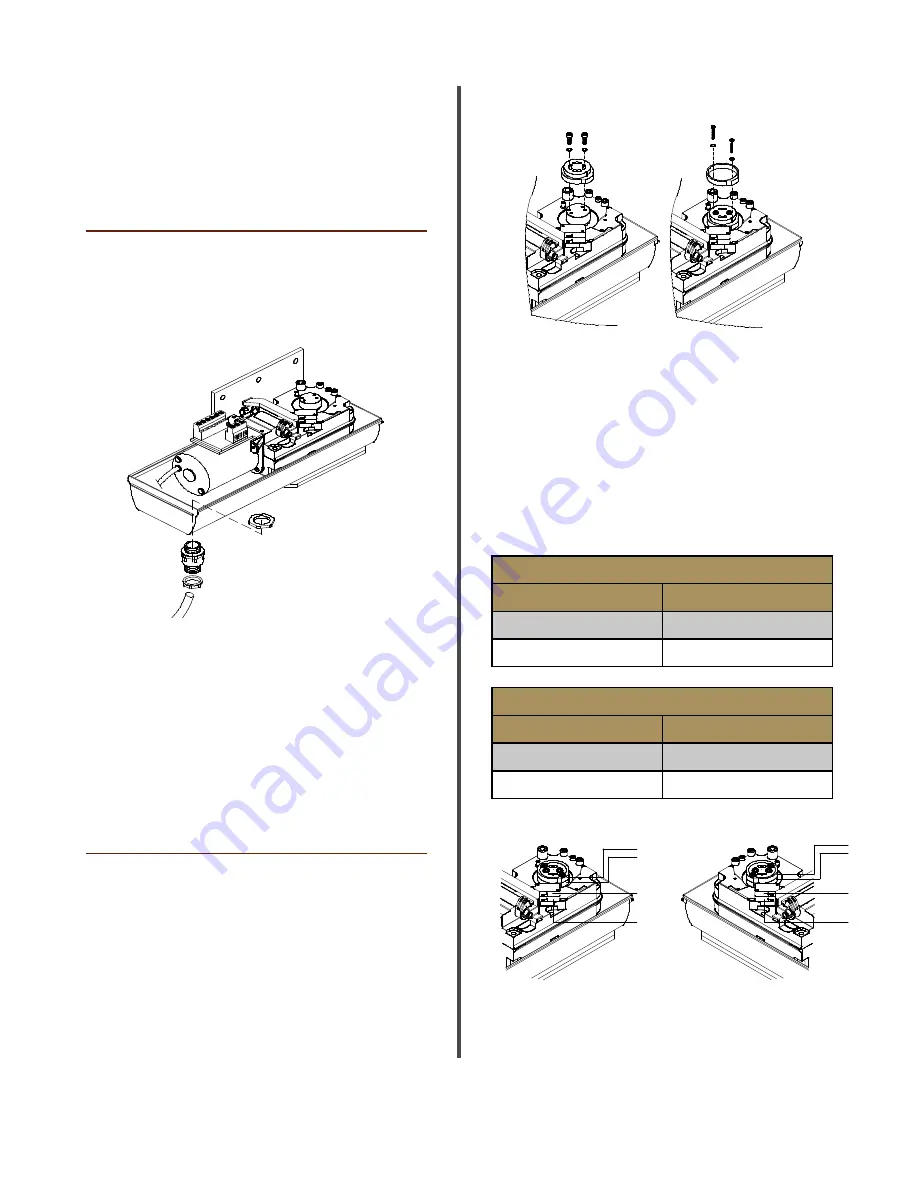

Installing the Limit Switches

1.

Install the full cam on top of the metal shaft

• Then install the ring cam on top of the full cam

•

Do not fully tighten the fixing screws

2. When the door is fully open, rotate the

corresponding cam (fig. 4), until you hear a

‘click’ indicating the limit switch has been

depressed

• Lock it in position by tightening the appropriate

screws

•

Repeat for the fully closed position

•

Refer to “Manual Operation Mode” to manually

swing the door.

3. Swing the door slowly to its open and close

positions, listening to see that the ‘click’ of the

limits switch occurs where desired

Note:

That the left motor’s cams (close vs open)

are inverted from those of the right motor. Adjust as

necessary

Left Motor (as viewed from inside)

Stop Position

Cam Position

Close

Top

Open

Bottom

Right Motor (as viewed from inside)

Stop Position

Cam Position

Close

Bottom

Open

Top

Installa

�

on

of

Limit

Switches

1.

Install

the

limit

‐

switch

refernce

cams

as

shown

in

g.

3.

Install

the

full

cam

on

top

of

the

metal

sha

�

,

then

install

the

ring

cam

on

top

of

the

full

cam.

Do

not

fully

�

ghten

the

screws.

2.

When

the

door

is

fully

open,

rotate

the

corresponding

cam

(

g.

4),

un

�

l

you

hear

a

‘click’

indica

�

ng

the

limit

switch

has

been

depressed,

then

lock

it

in

posi

�

on

by

�

ghtening

the

appropriate

screws.

Repeat

for

the

fully

closed

posi

�

on.

Refer

to

“Manual

Opera

�

on

Mode”

to

manually

swing

the

door.

3.

Swing

the

door

slowly

to

its

open

and

close

posi

�

ons,

listening

to

see

that

the

‘click’

of

the

limits

switch

occurs

where

desired.

Adjust

as

necessary.

Fig

4.

Limit

Switch

func

�

ons

LEFT

MOTOR

(viewed

from

inside)

RIGHT

MOTOR

(viewed

from

inside)

CLOSE

LIMIT

CAM

OPEN

LIMIT

CAM

CLOSE

LIMIT

SWITCH

OPEN

LIMIT

SWITCH

OPEN

LIMIT

CAM

CLOSE

LIMIT

CAM

OPEN

LIMIT

SWITCH

CLOSE

LIMIT

SWITCH

Fig

3.

Limit

Switch

installa

�

on

FULL

CAM

RING

CAM

Franklin Autoswing Installation Manual

TM

10

© 2012 Copyright Real Carriage Door Company, Inc

1.

Locate

the

control

housing

containing

the

LIBRA

‐

UL

‐

R

panel.

2.

For

moun

�

ng,

the

rear

of

the

housing

must

be

predrilled.

Refer

to

g.

5

for

the

loca

�

ons

of

the

holes

to

be

drilled.

3.

At

this

�

me,

plan

where

you

would

like

to

run

the

wiring

into

the

housing

and

predrill

for

stress

‐

relief

connectors.

Be careful

not to damage the panel when drilling into the housing! It is a

good idea to remove the panel while drilling.

4.

Mount

the

housing

securely,

using

either

screws

or

drywall

anchors

(not

supplied).

Be

careful

not

to

damage

any

wires

or

components

of

the

board.

(See

“Typical

System

Overview”

for

suggested

loca

�

on

of

the

housing)

Moun

�

ng

the

Control

Housing

Fig

5.

Moun

�

ng

loca

�

ons

Fig

6.

Stress

relief

connector

1.

Locate

the

stress

relieving

cord

‐

grip.

2.

A

�

ach

connec

�

ng

nut

(F)

to

grip

body

(G).

Tighten

securely

using

nger

pressure

only.

3.

Slip

compression

nut

(H)

over

a

length

of

18/3

(18

Gauge,

3

strand)

motor

wire

and

thread

wire

through

the

assembled

cord

‐

grip.

4.

Tighten

the

compression

nut

(H)

with

nger

pressure

only.

5.

Refer

to

“Master

Wiring

Diagram”

to

wire

the

motor

to

the

LIBRA

‐

UL

‐

R

control

panel.

6.

For

basic

programming

see

“General

Programming.”

For

advanced

parameters,

please

see

the

BFT

“LIBRA

‐

UL

‐

R

Installa

�

on and User’s Manual”

Wiring

the

Motor

F

G

H

WIRE

USE

min

18/3

wire*

connec

�

ng

motors

to

control

panel

min

22/4

wire

connec

�

ng

RX

photoeye

to

control

panel

min

22/2

wire

connec

�

ng

TX

photoeye

to

control

panel

*Use stranded wire. Increase gauge if motors more than 20’ from panel

TM

Franklin Autoswing Installation Manual

© 2012 Copyright Real Carriage Door Company, Inc

11

Installa

�

on

of

Limit

Switches

1.

Install

the

limit

‐

switch

refernce

cams

as

shown

in

g.

3.

Install

the

full

cam

on

top

of

the

metal

sha

�

,

then

install

the

ring

cam

on

top

of

the

full

cam.

Do

not

fully

�

ghten

the

screws.

2.

When

the

door

is

fully

open,

rotate

the

corresponding

cam

(

g.

4),

un

�

l

you

hear

a

‘click’

indica

�

ng

the

limit

switch

has

been

depressed,

then

lock

it

in

posi

�

on

by

�

ghtening

the

appropriate

screws.

Repeat

for

the

fully

closed

posi

�

on.

Refer

to

“Manual

Opera

�

on

Mode”

to

manually

swing

the

door.

3.

Swing

the

door

slowly

to

its

open

and

close

posi

�

ons,

listening

to

see

that

the

‘click’

of

the

limits

switch

occurs

where

desired.

Adjust

as

necessary.

Fig

4.

Limit

Switch

func

�

ons

LEFT

MOTOR

(viewed

from

inside)

RIGHT

MOTOR

(viewed

from

inside)

CLOSE

LIMIT

CAM

OPEN

LIMIT

CAM

CLOSE

LIMIT

SWITCH

OPEN

LIMIT

SWITCH

OPEN

LIMIT

CAM

CLOSE

LIMIT

CAM

OPEN

LIMIT

SWITCH

CLOSE

LIMIT

SWITCH

Fig

3.

Limit

Switch

installa

�

on

FULL

CAM

RING

CAM

Franklin Autoswing Installation Manual

TM

10

© 2012 Copyright Real Carriage Door Company, Inc