1. Place both thumbs on the camera ball assembly, above the

camera lens.

2. Push your thumbs downwards, whilst pulling the cover away

from the base of the camera with the rest of your grip.

3. Once the cover is detached, slide it up and off the camera.

Making internal connections

If there is limited space or you want the cable connection to be

made internally follow the steps below.

D12848-1

1. Remove the camera’s outer cover.

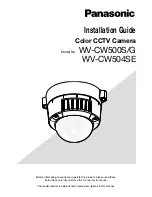

2. Unscrew the light grey cable capture nuts on both of the

cable glands on the base of the camera.

3. Pull the rubber glands and clamping claws out of the bore

holes.

4. Pull both cables up through the base.

5. Remove the rubber gland, clamping claw and capture nut

from both cables.

6. Connect the camera’s ethernet cable to one end of the

ethernet coupler (supplied).

7. Thread the external ethernet and video cables through the

bore holes.

8. Thread the external ethernet cable through the rubber gland,

clamping claw and capture nut.

9. Connect the external ethernet cable to the other end of the

ethernet coupler.

10. Using the zip ties (supplied) secure the ethernet coupler to

the rear of the camera ball assembly.

11. Pull any excess cable back through the bore hole.

12. Secure the ethernet cable by reassembling the rubber gland

and clamping claw into the bore hole and tightening the

capture nut.

13. Feed the camera’s video cable around the front of the

camera ball assembly.

14. Apply Locktite to both ends of a female to female connector.

15. Connect a female to female connector to the camera’s video

cable.

D12856-1

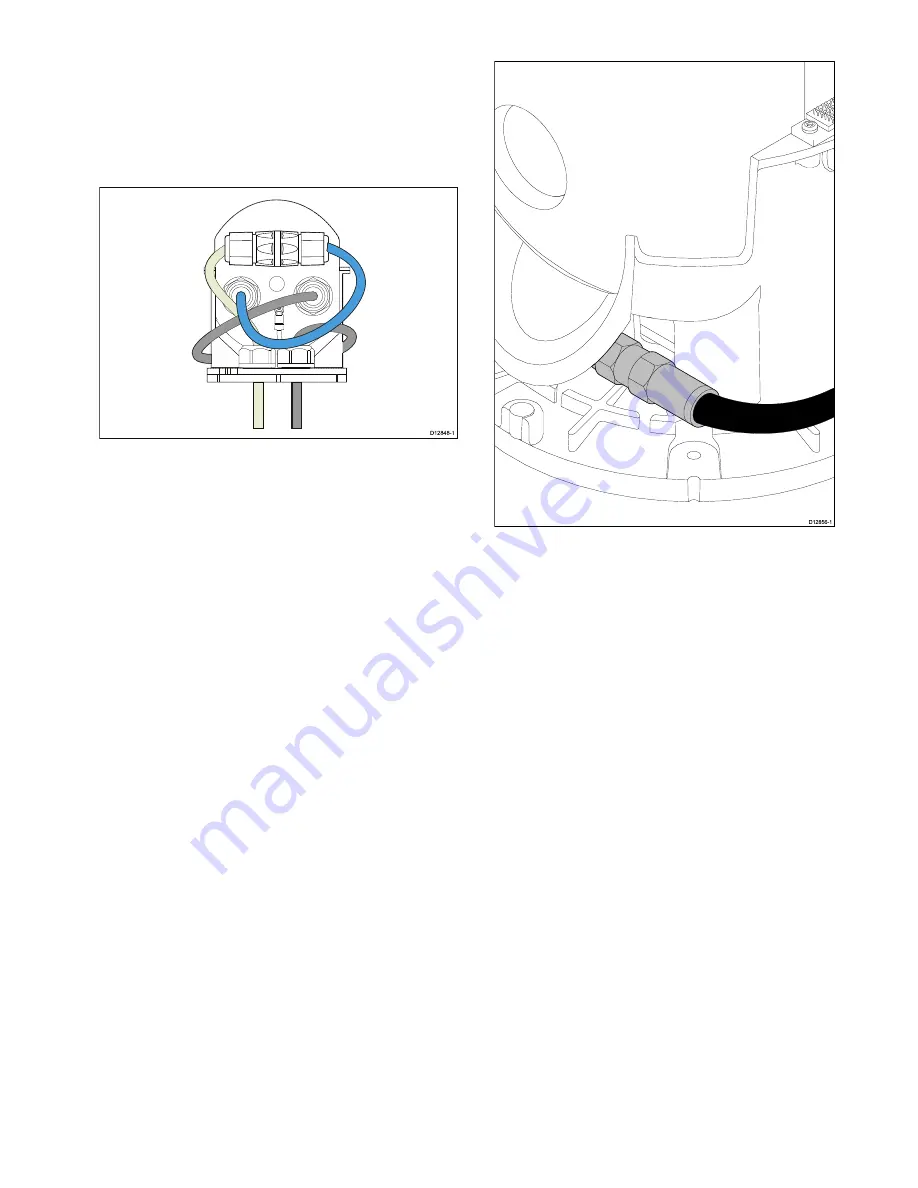

16. Feed the external video cable through the bore hole.

17. Connect the external video cable to the other end of the

female to female connector.

18. Wrap the video connection with marine grade sealing tape

(e.g. 3M Scotch-Seal 2229 or equivalent).

19. Secure the video cable to the front of the ball assembly using

the zip tie (supplied).

20. Pull any excess cable back through the bore hole.

21. Secure the video cable by reassembling the rubber gland

and clamping claw into the bore hole and tightening the

capture nut.

Installation