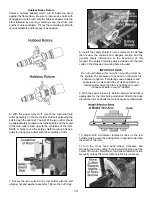

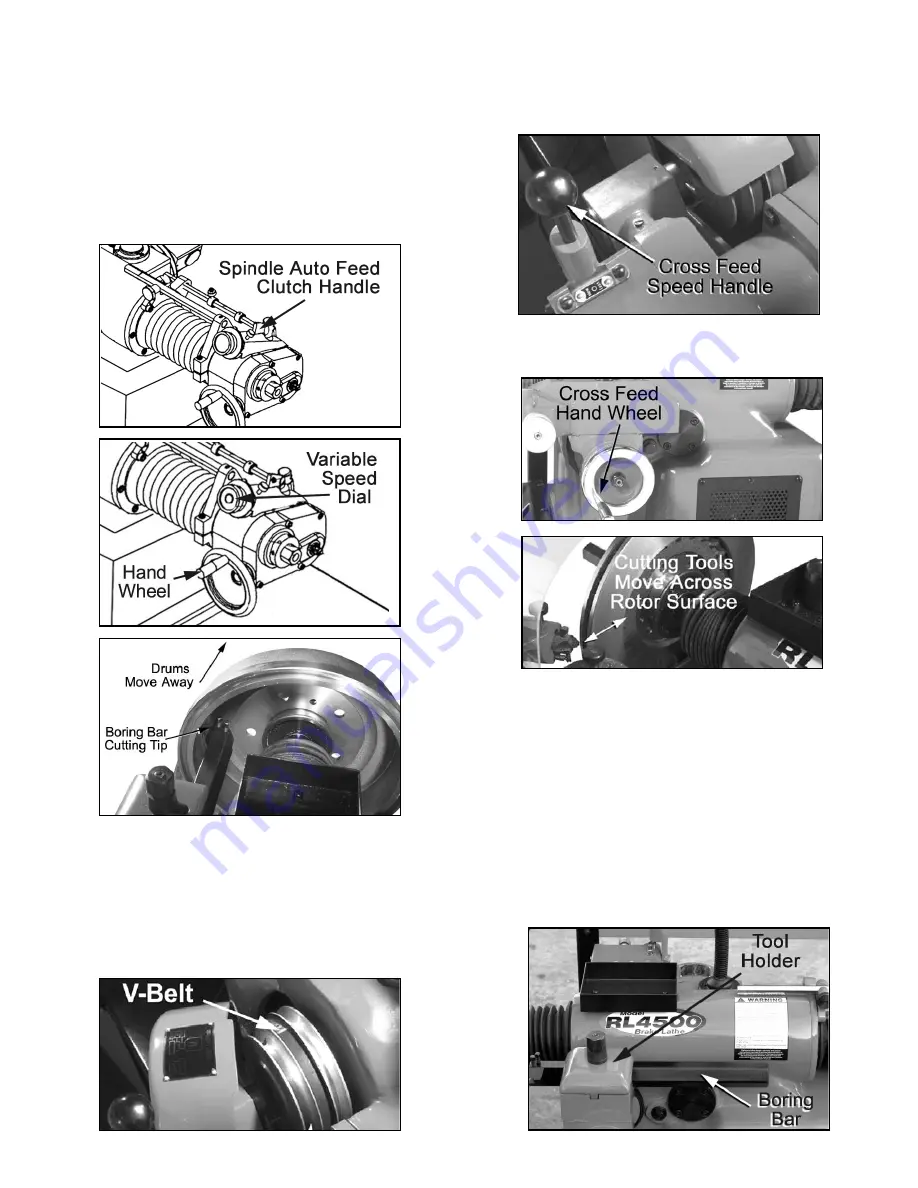

Horizontal Spindle / Arbor Feed

By engaging the spindle feed clutch handle, the spindle

and arbor will move the mounted brake drum to the left.

This feeds the drum braking surface across the cutting

tool (boring bar) as the drum moves away. Spindle feed

may also be done manually without engaging the spindle

feed clutch handle by using the spindle feed hand wheel.

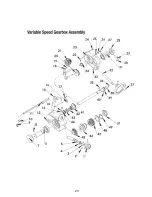

Spindle feed rate refers to the distance the spindle is

moved for each revolution. This speed is variable and can

be adjusted using the spindle variable speed dial.

IMPORTANT NOTE

Spindle feed must be adjusted with the lathe running.

Do not try to move any feed levers or dials without the

drive motor running. Damage may occur to the gears.

Spindle Speed

Spindle speed is adjustable by changing the position of

the V-belt pulley on the rear of the lathe. See page 17.

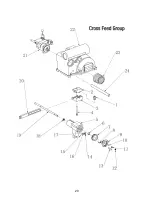

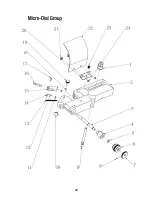

Cross Feed

The cross feed (forward and aft) draws the tool bit ( micro-

dial twin cutters or boring bar ) across the face of a brake

rotor or flywheel when the cross feed speed setting handle

is engaged.

The cross feed may also be operated manually without

engaging the feed handle using the cross feed hand wheel.

RECONDITIONING BRAKE DRUMS

1. After the following instructions are read and understood,

obtain a scrap drum for practice. First determine if the drum

will be within factory recommended limits after resurfacing is

performed. The DISCARD diameter is often cast or stamped

into brake drums, not the maximum machining diameter.

2. Inspect the brake drum. Do not attempt to machine a drum

that is damaged, excessively worn or in poor condition.

3. Install the boring bar tool holder and boring bar as shown.

9