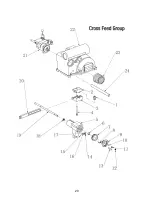

19. Manually turn the cross feed hand wheel

counterclockwise and move the cutting tools outward

toward the edge of the rotor to remove any rust build-up or

high areas on the outer edge.

20. After cleaning up the outer edge of the rotor manually

feed the cutting tools inward towards the center of the rotor

to a point slightly beyond the contact surface of the brake

pads being careful not to run the carbide inserts into the

hub portion of the rotor.

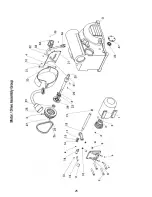

21.Turn both tool bit controls (OUTER KNURLED

KNOBS) to the desired depth-of cut then lock them in

position by tightening the dial lock knobs.

USE THESE GENERAL GUIDELINES

TO DETERMINE THE DEPTH-OF-CUT

Either rough or finish cuts may be taken to resurface a

rotor. Generally, finish cuts should be 0.004” (0.10 mm)

to 0.006” (0.15 mm) per side. Very shallow cuts of less

than 0.004” (10 mm) per side tend to reduce tool bit life

because the heat generated during reconditioning isn’t

transferred to the rotor efficiently. Rough cuts may be

taken from 0.006” to 0.010” per side.

IMPORTANT NOTE

Hold OUTER knobs with one hand and turn CLOCK-

WISE to move cutting tips inward towards rotor. There

are 10 large graduations on each dial indicator. Each mark

represents 0.002” english ( 0.05 mm metric ).

22. Engage the automatic cross feed to begin the cut by

moving the lever to the desired speed. The cross feed will

stop automatically when the cutting tools have moved all

the way across the face of the rotor.

IMPORTANT NOTE

For roughing cuts, move the cross feed lever to the

FAST position. Rough cuts may be taken from 0.006” to

0.010” per side.

23. Manually feed the cutting tools inward towards the

center of the rotor to a point slightly beyond the contact

surface of the brake pads being careful not to run the

carbide inserts into the hub portion of the rotor.

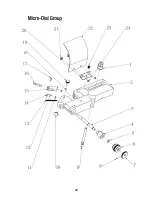

24. Turn the end knob of each tool bar micro-dial

individually to set each tool bit to the desired depth-of cut.

Remove only enough material to clean up each side.

25. Engage the automatic cross feed to begin another cut.

26. When the tool bits have cleared the rotor, disengage

the cross feed and turn the lathe OFF.

27. Inspect the brake surfaces. If part of the surface was

not cut, leave the tool bars locked in position, turn the

lathe ON, slowly turn the cross feed handwheel clockwise

until the outer tool reaches the groove at the rotor hub,

and repeat steps 20 -23.

28. Repeat steps until a smooth finish cut is made.

16