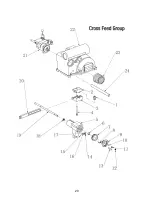

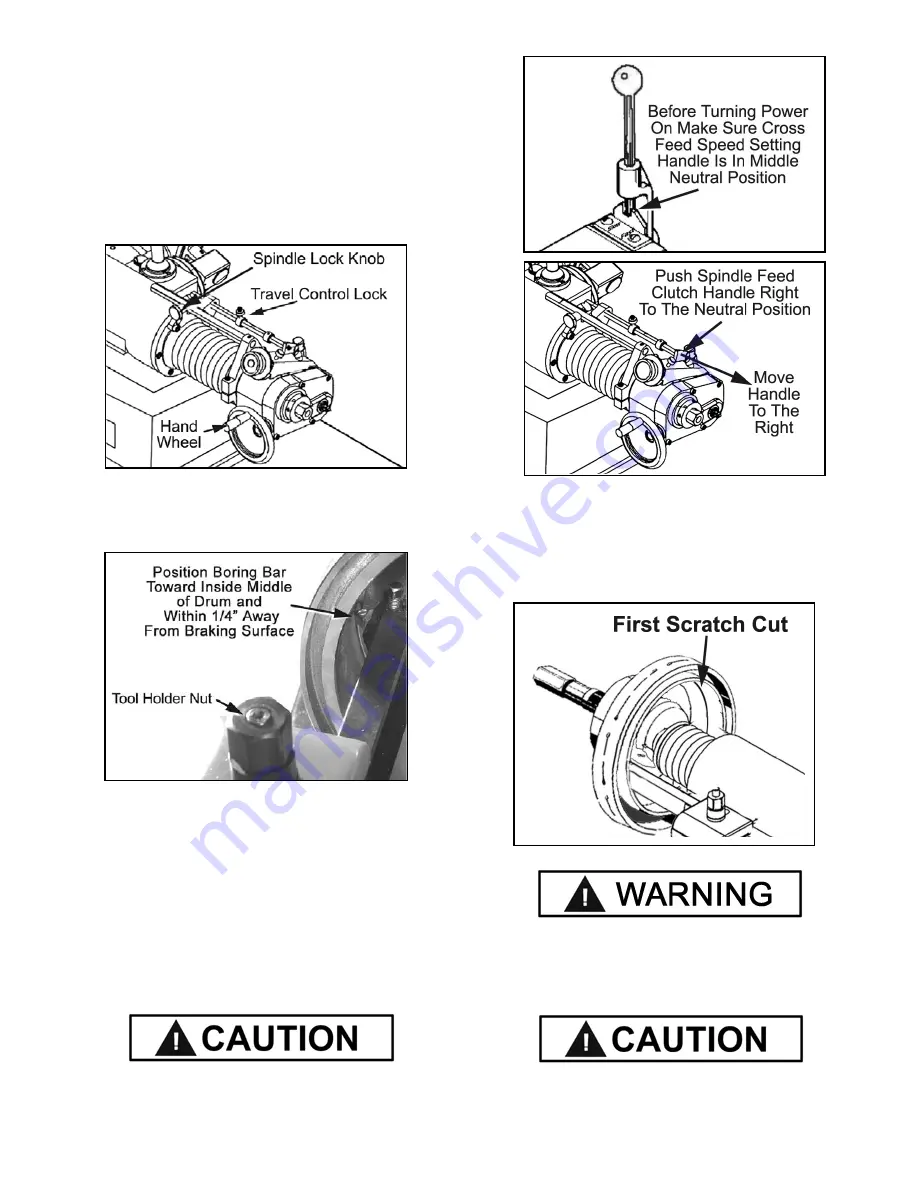

7. Using the cross feed hand wheel, move the cross feed

to its innermost position by turning the hand wheel

clockwise.

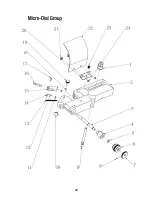

8. Using the spindle feed hand wheel, move the spindle to

its innermost (right hand) position by turning the hand

wheel clockwise and then back off by turning dial wheel

five turns counterclockwise. NOTE: If the hand wheel does

not turn freely, check to make sure the spindle lock and

travel control lock knobs are loosened.

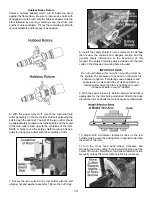

9. Next, position the boring bar by loosening the tool holder

nut and sliding the boring bar towards the innermost side of

the drum, within 1/4” away from the braking surface.

IMPORTANT NOTE

The boring bar position will have to be changed

whenever a drum of different diameter is machined. The

entire boring bar tool holder may be swiveled to achieve

the best cutting position.

10. Check all clearances closely to make sure that nothing

will “crash” when the power is turned on and the drum

starts rotating. NOTE: It may help to turn the arbor nut

counter-clockwise and manually turn the drum by hand to

pre-check all clearances.

Before turning the power on, make sure the cross feed

speed setting handle and the spindle feed clutch handle

are in their neutral positions.

11. Turn the power on.

12. Turn the cross feed hand wheel counterclockwise and

bring the boring bar cutting tip into the braking surface

until it just barely contacts the drum surface and makes a

slight scratch cut.

KEEP HANDS clear of moving parts at all times. Keep

hair, loose clothing, neckties, shop rags, jewelry, fingers,

and all parts of body away from moving parts.

Always wear safety glasses or a face shield. Cutting an

exposed surface such as a brake drum or rotor will

produce flying chips and debris.

11