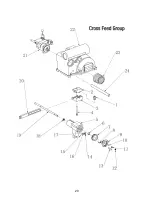

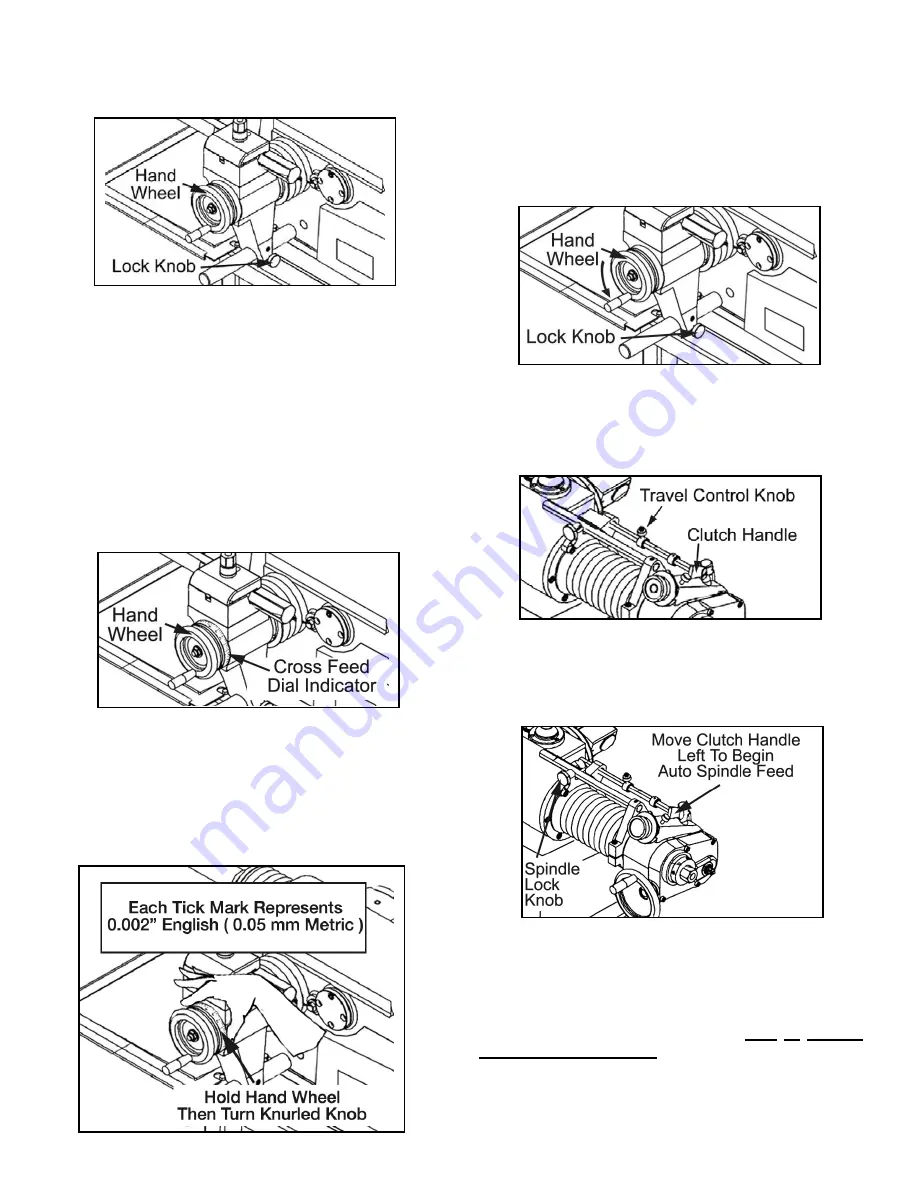

IMPORTANT NOTE

If the hand wheel does not turn freely, check to make

sure the cross feed lock knob is loosened.

13. Examine the scratch cut making sure it is uniform

around the entire circumference of the drum. If the scratch

cut appears to be deeper on one side of the drum and not

a uniform depth, then turn the power off, remove the drum

from the arbor, check the mounting adapters and arbor for

nicks, burrs, or chips, then remount the drum, and repeat

steps 4 - 13 until a uniform scratch cut is achieved.

14. Holding the cross feed hand wheel firmly in position with

your left hand, carefully rotate the cross feed dial indicator

(the outer, knurled knob) with your right hand until ZERO is

positioned at top dead center and lined up with the tick mark.

This will give you an initial zero-set starting point.

15. Turn the spindle feed hand wheel clockwise until the

boring bar reaches the innermost part of the drum. Be

careful not to crash the boring bar and cutting tip on the

inside wall of the drum or damage to tooling may result.

16. There are 100 graduations on the dial indicator. Each

tick mark represents 0.002” ( 0.05 mm metric ).

GUIDELINES TO DETERMINE THE DEPTH-OF-CUT

• Rough cuts should be no deeper than 0.020”.

• Finish cuts should be no shallower than 0.004” deep.

17. With the lathe running, turn the cross feed hand wheel

dial counterclockwise to the depth desired and then lock

the cross feed by tightening the lock knob.

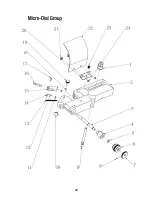

18. Set the automatic feed shut-off by sliding the travel control

lock knob on the limit rod to a point that approximately equals

the depth of the drum and tighten the knob in place. The limit

rod will then automatically disengage the clutch handle and

stop the spindle feed when it reaches this point.

19. Double check to make sure the spindle lock knob is

loosened then engage the spindle feed clutch handle (move

to the left) to begin auto-feed drum resurfacing. To make sure

the clutch gear is fully engaged, hold the clutch handle to the

left until the spindle feed handwheel starts turning.

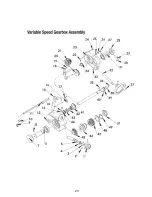

By engaging the spindle feed clutch handle, the spindle and

arbor will move the mounted brake drum to the left. The

spindle feed rate can be adjusted by using the spindle

variable speed dial. Adjust the feed rate depending on the

surface finish you desire. Fast for rough cuts and slower for

finish cuts.

REMEMBER!

Spindle feed must be adjusted

with the lathe running only. Do not try to adjust speed dial

without the drive motor running or gear damage will occur.

20. After the first cut is made, repeat steps 14 - 19 until a

smooth finish cut is made.

12